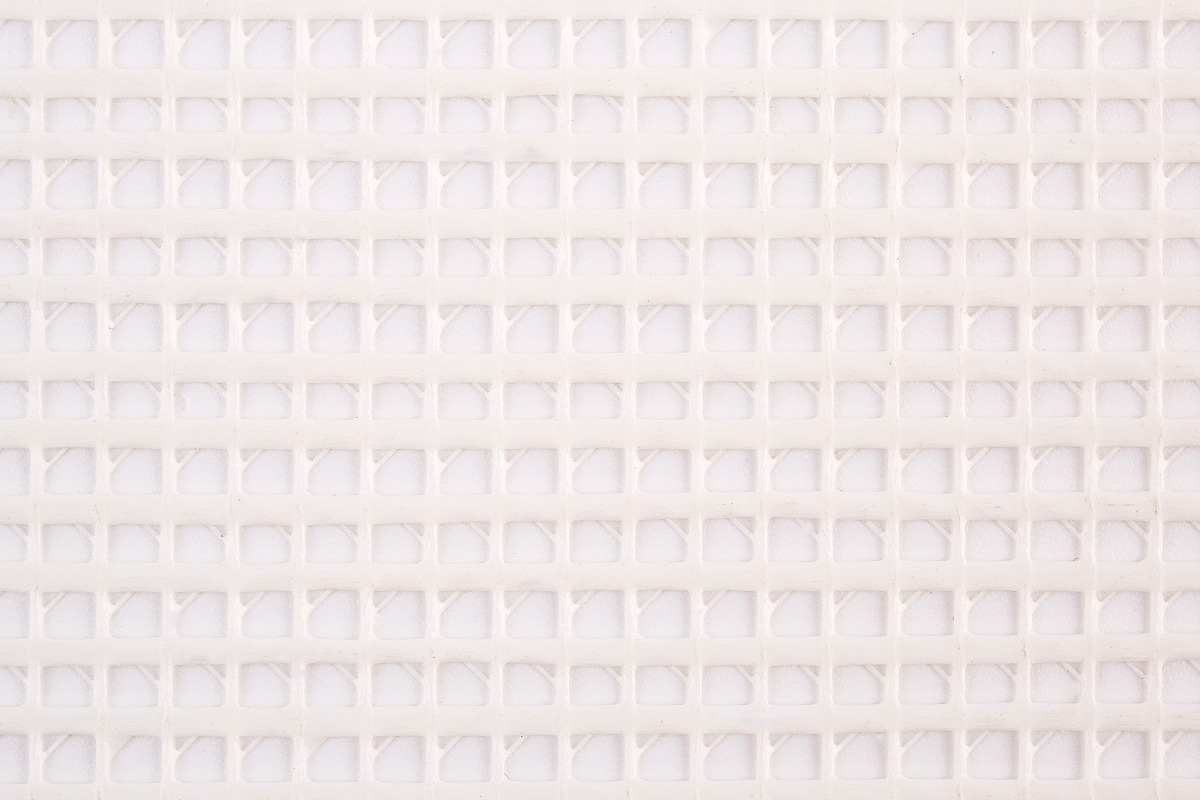

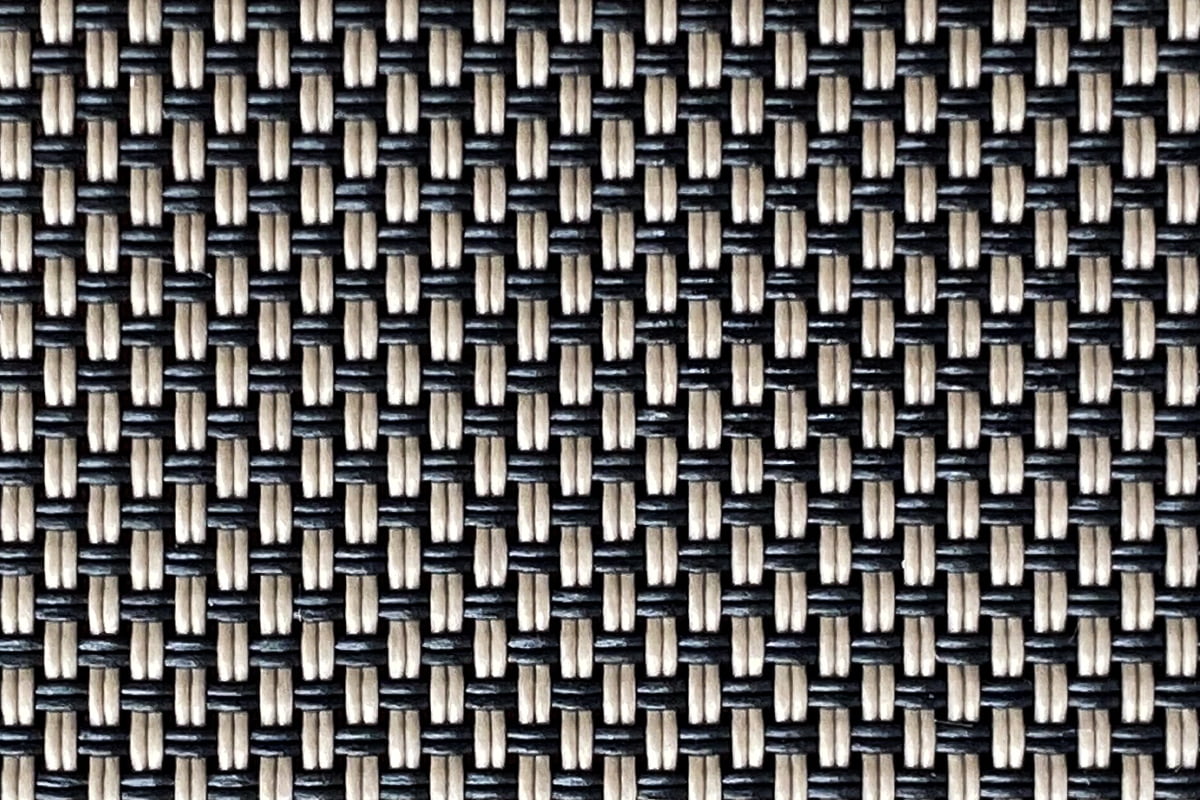

PVC mesh fabric is widely used in applications such as outdoor furniture, banners, tents, and construction projects. Choosing a reliable PVC mesh fabric factory is crucial for ensuring consistent quality, timely delivery, and competitive pricing. Understanding what to look for can help businesses make informed decisions and establish lasting partnerships.

Evaluate Experience and Expertise

One of the factors to consider when selecting a PVC mesh fabric factory is its experience in the industry. A factory with years of production experience is more likely to understand material standards, manufacturing processes, and quality control. Experienced factories can provide guidance on suitable fabric types, thicknesses, and coatings to meet specific application requirements.

Checking for certifications, technical expertise, and a history of working with reputable clients can give additional confidence in a factory's capabilities. Experienced factories are also better equipped to handle large orders and custom specifications.

Inspect Production Capabilities

Assessing production capabilities is essential when choosing a PVC mesh fabric factory. This includes the factory's machinery, output capacity, and ability to maintain consistent quality. Modern weaving and coating equipment can improve the durability, strength, and finish of PVC mesh fabric.

Factories that can provide samples or small trial orders allow clients to evaluate material quality before committing to bulk purchases. Understanding times, order flexibility, and scalability is important, especially for businesses with fluctuating or high-volume demands.

Quality Control Measures

Quality control is a key aspect of a reliable PVC mesh fabric factory. Factories should have established procedures to inspect raw materials, production stages, and finished products. Testing for tensile strength, colorfastness, and coating uniformity ensures that the PVC mesh fabric meets performance standards.

A factory that prioritizes quality control is less likely to produce defective batches or inconsistent materials. Requesting product certifications, inspection reports, or visiting the factory can provide assurance of their quality management practices.

Consider Customization and Service

Many projects require PVC mesh fabric with specific patterns, colors, or coatings. A reliable PVC mesh fabric factory should offer customization options and be willing to work with clients to meet unique requirements. This includes adjusting mesh size, thickness, or applying special coatings for UV resistance, waterproofing, or fire retardancy.

In addition to production capabilities, service quality matters. Responsive communication, technical support, and problem-solving skills indicate a factory that values client relationships and long-term cooperation.

Evaluate Reputation and References

Checking the reputation of a PVC mesh fabric factory can provide insight into reliability. Online reviews, industry forums, and client testimonials help assess past performance. Asking the factory for references or case studies can demonstrate their ability to handle orders similar to your needs.

A factory with a consistent record of on-time delivery, quality assurance, and client satisfaction is more likely to be a dependable partner. Reliability, transparency, and experience together ensure smoother collaboration and fewer operational risks.

Choosing a reliable PVC mesh fabric factory involves evaluating experience, production capabilities, quality control, customization options, and reputation. By carefully assessing these factors, businesses can select a factory that consistently delivers high-quality materials, supports project requirements, and fosters long-term partnerships.

en

en Español

Español