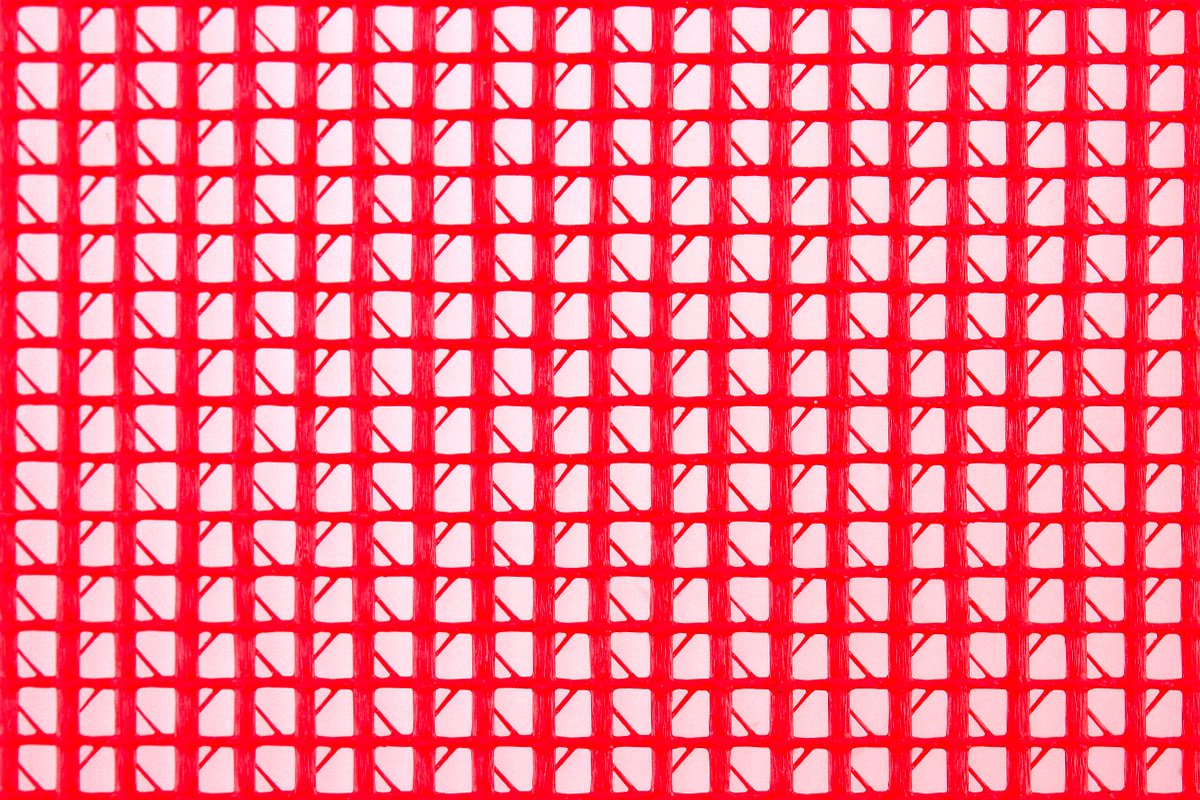

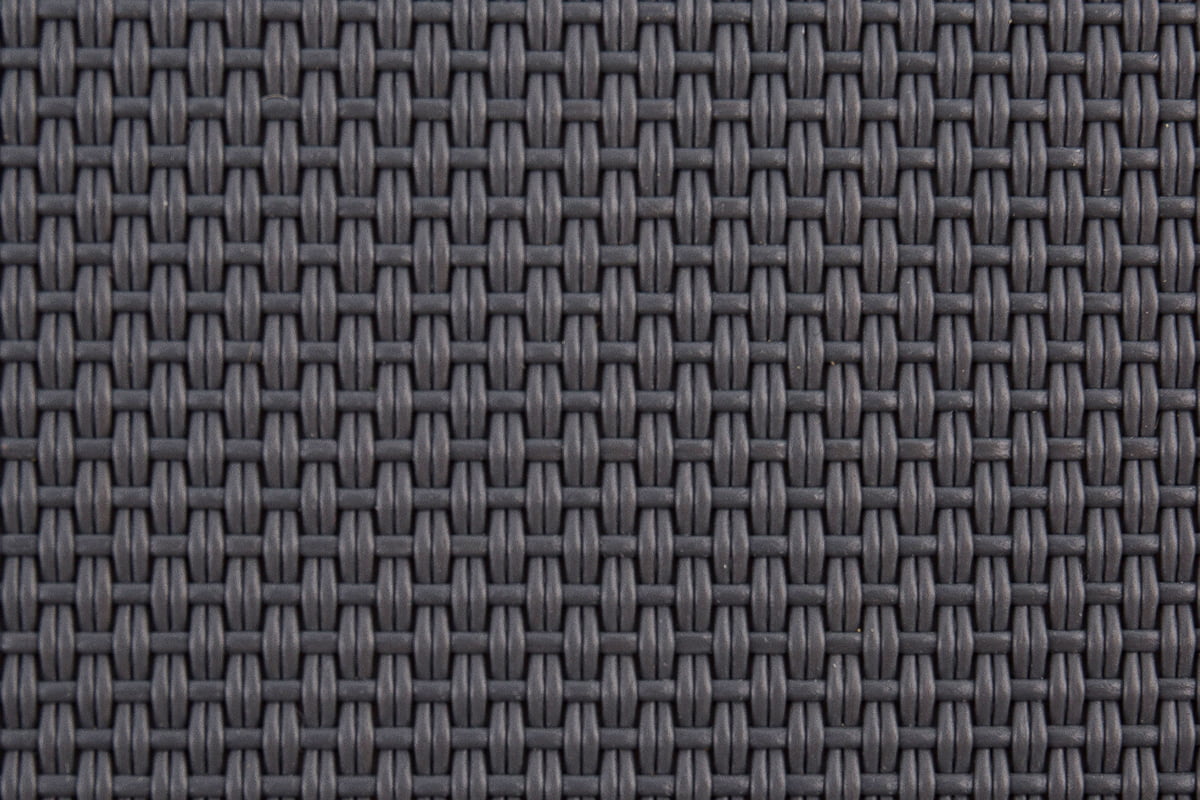

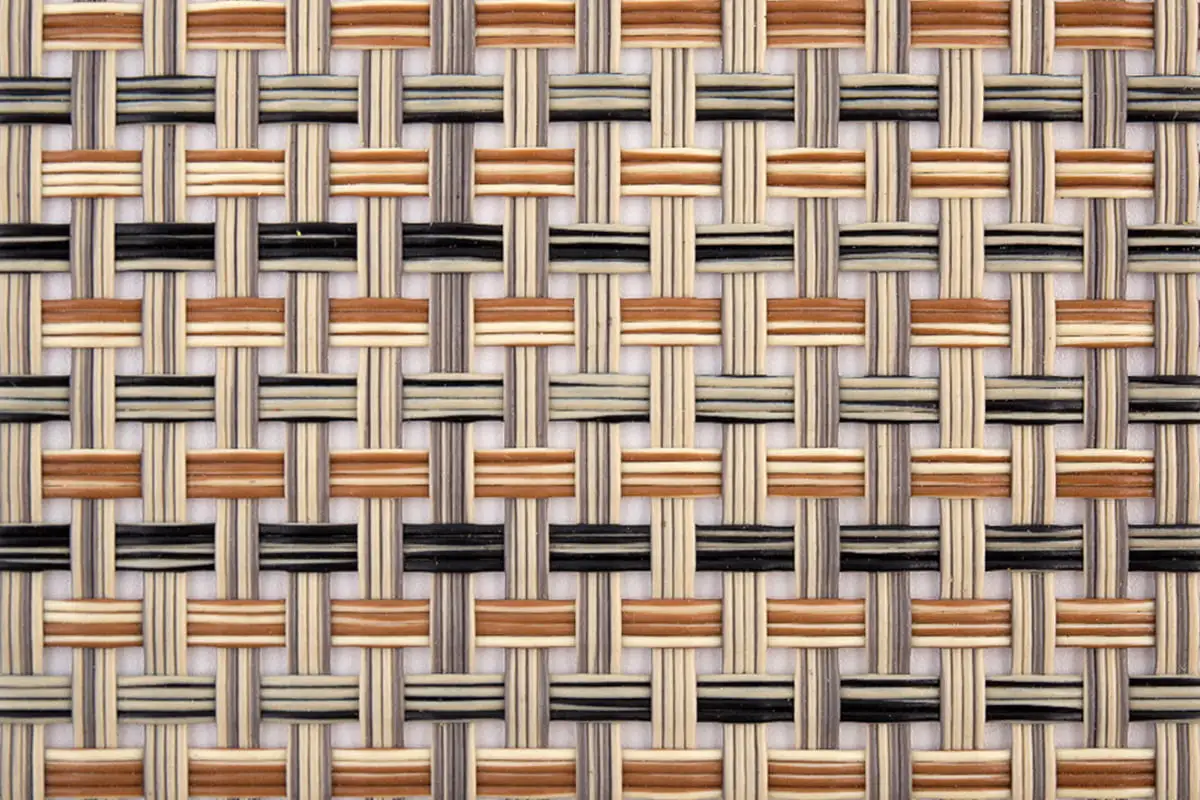

Vinyl woven mesh fabric is widely used in industries ranging from construction and agriculture to furniture and outdoor applications. Beyond its durability and versatility, there is increasing interest in the environmental impact of this material. Understanding why vinyl woven mesh fabric can be considered environmentally friendly helps businesses and consumers make more sustainable choices.

1. Use of Recyclable Materials

One factor that enhances the environmental friendliness of vinyl woven mesh fabric is its recyclability. Many manufacturers source vinyl polymers that can be collected, processed, and reused at the end of the product's life. This reduces the demand for virgin materials and lowers waste in landfills. Vinyl woven mesh fabric manufacturers often design products with recycling in mind, making it easier to recover and repurpose the material after use.

2. Durability and Long Lifespan

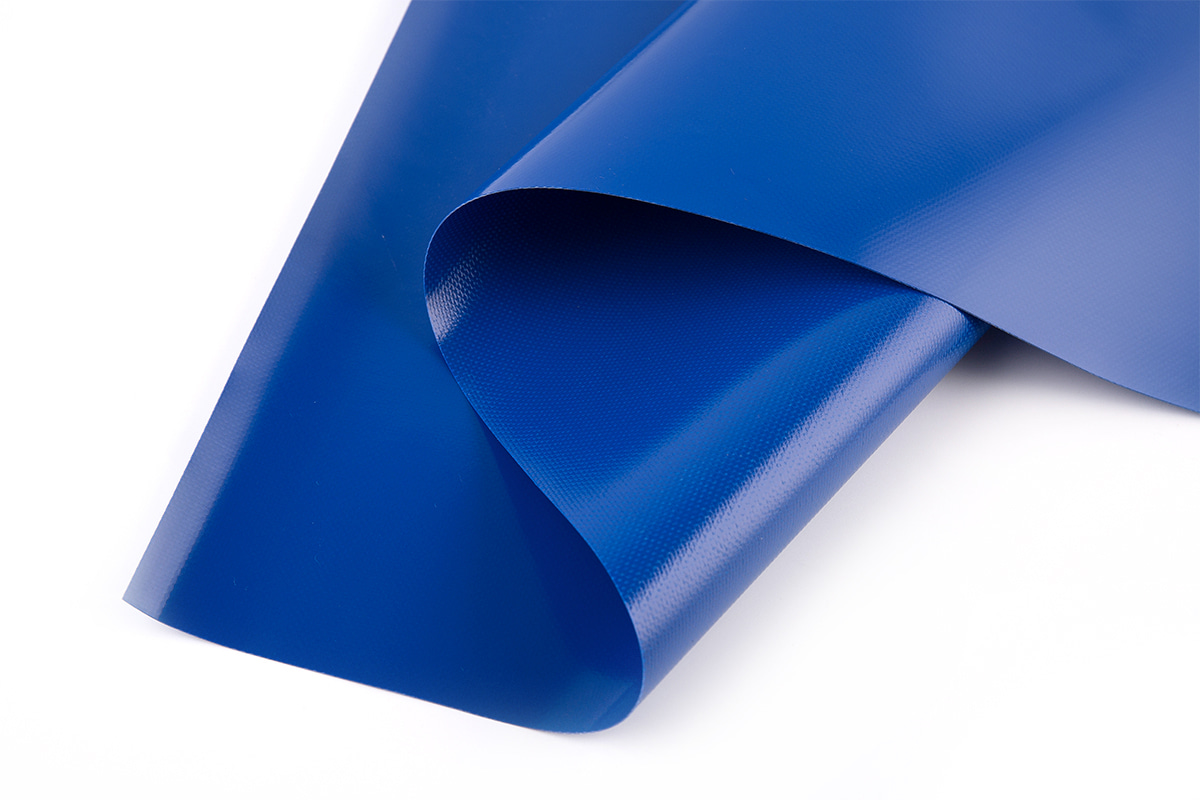

Durability is another key element of sustainability. Vinyl woven mesh fabric is resistant to tearing, UV exposure, mold, and moisture, which allows it to last longer than many alternative materials. Products with extended lifespans reduce the frequency of replacement, lowering overall material consumption and waste. By producing fabrics that endure harsh conditions, vinyl woven mesh fabric manufacturers contribute to more sustainable applications in various industries.

3. Low Maintenance and Reduced Resource Use

Vinyl woven mesh fabric requires minimal maintenance, which contributes to its environmental profile. Unlike fabrics that need frequent cleaning, special treatments, or chemical products, vinyl mesh can often be cleaned with water or mild detergents. This reduces water usage, chemical runoff, and energy consumption over the product's lifetime. Materials that demand fewer resources for upkeep are naturally more environmentally friendly.

4. Production Practices and Energy Efficiency

Environmentally conscious vinyl woven mesh fabric manufacturers also focus on efficient production processes. Advances in weaving technology and extrusion methods can reduce energy consumption during fabrication. Some factories implement recycling of scrap materials, use non-toxic additives, and optimize energy use to minimize environmental impact. By combining durable materials with eco-conscious production, manufacturers enhance the overall sustainability of vinyl woven mesh fabric.

5. Contribution to Eco-Friendly Applications

Vinyl woven mesh fabric is often used in applications that support environmental initiatives. For example, it is employed in agricultural shade structures, erosion control, and outdoor protective covers, reducing water loss and promoting sustainable farming practices. Its lightweight and breathable properties also make it suitable for reusable items, further limiting disposable material waste. In this way, the fabric's functionality aligns with environmentally responsible usage.

6. Certifications and Compliance

Many vinyl woven mesh fabric manufacturers adhere to environmental standards and certifications, which verify that the material and production processes meet sustainability criteria. Compliance with regulations such as REACH or OEKO-TEX ensures that the fabric is free from harmful chemicals and produced responsibly. These certifications provide assurance to buyers that the products they choose are not only functional but also aligned with environmental goals.

Vinyl woven mesh fabric can be considered environmentally friendly due to its recyclability, durability, low maintenance requirements, and responsible production practices. Additionally, its applications often support sustainable solutions in agriculture, construction, and everyday use. By combining material resilience with energy-efficient manufacturing and eco-conscious design, vinyl woven mesh fabric manufacturers provide products that reduce environmental impact while maintaining functionality. Choosing these fabrics is a practical step toward more sustainable consumption in multiple industries.

en

en Español

Español