Car seat belt webbing is a critical safety component in vehicles, designed to restrain passengers during collisions and sudden stops. The strength and reliability of the webbing directly affect its ability to protect occupants. Manufacturers employ rigorous testing methods to ensure that seat belt webbing meets safety standards and performs consistently under demanding conditions.

Understanding Seat Belt Webbing

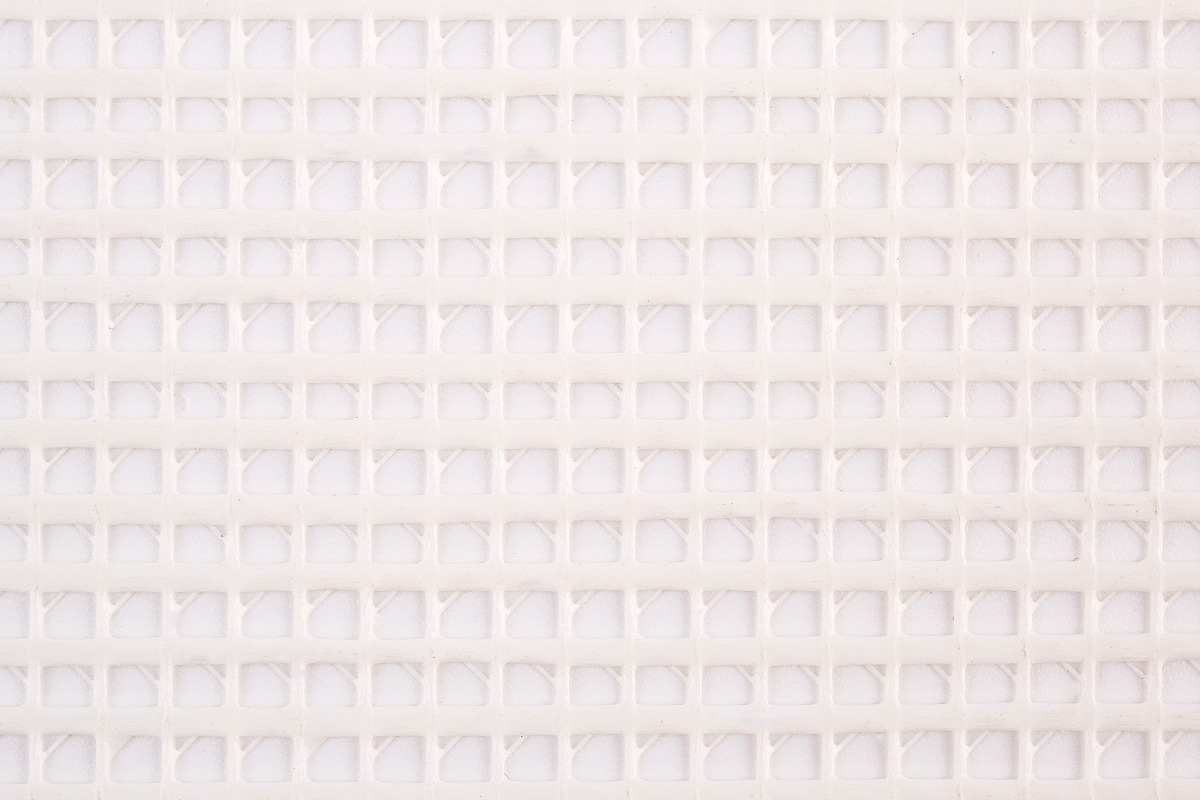

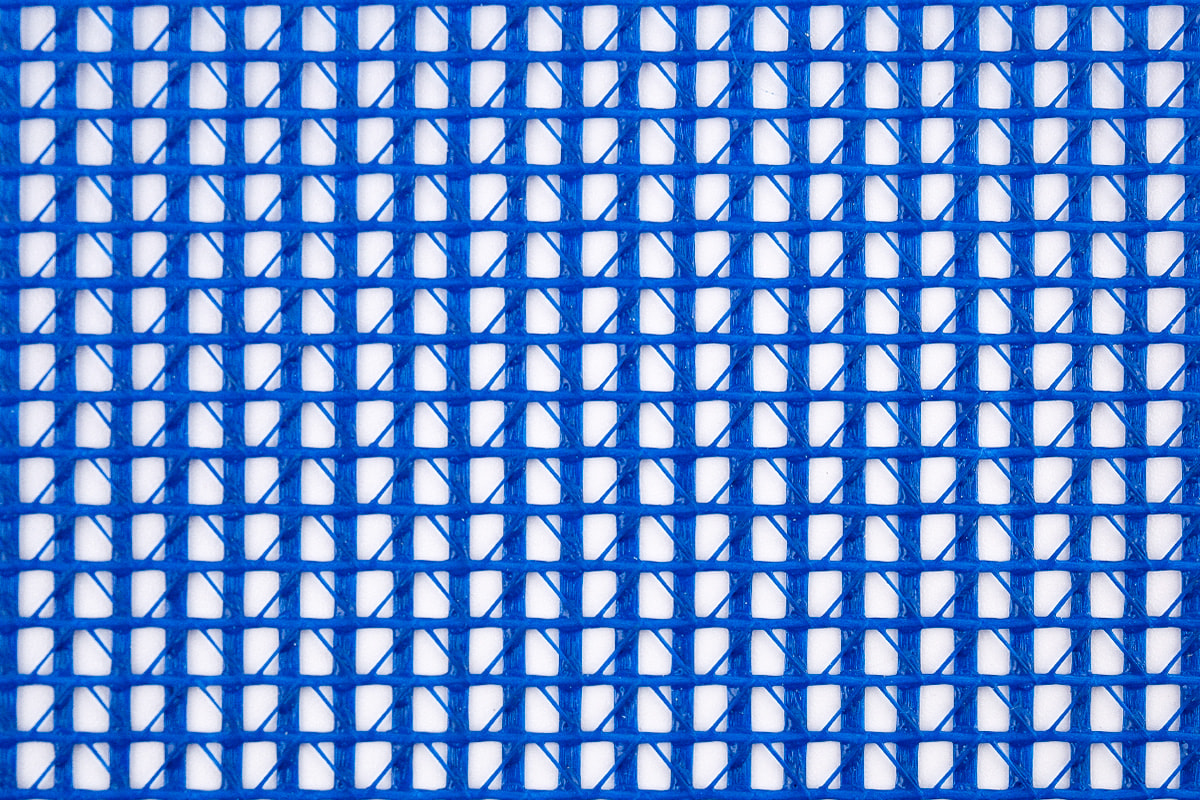

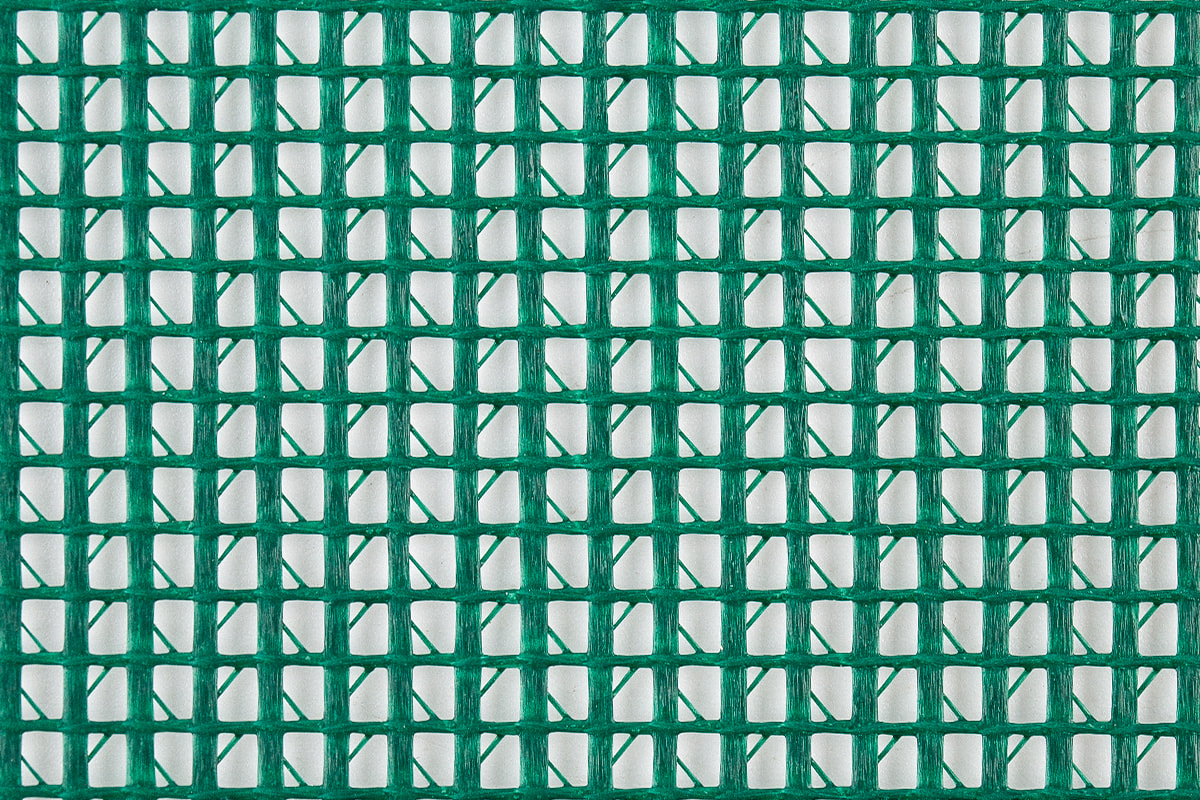

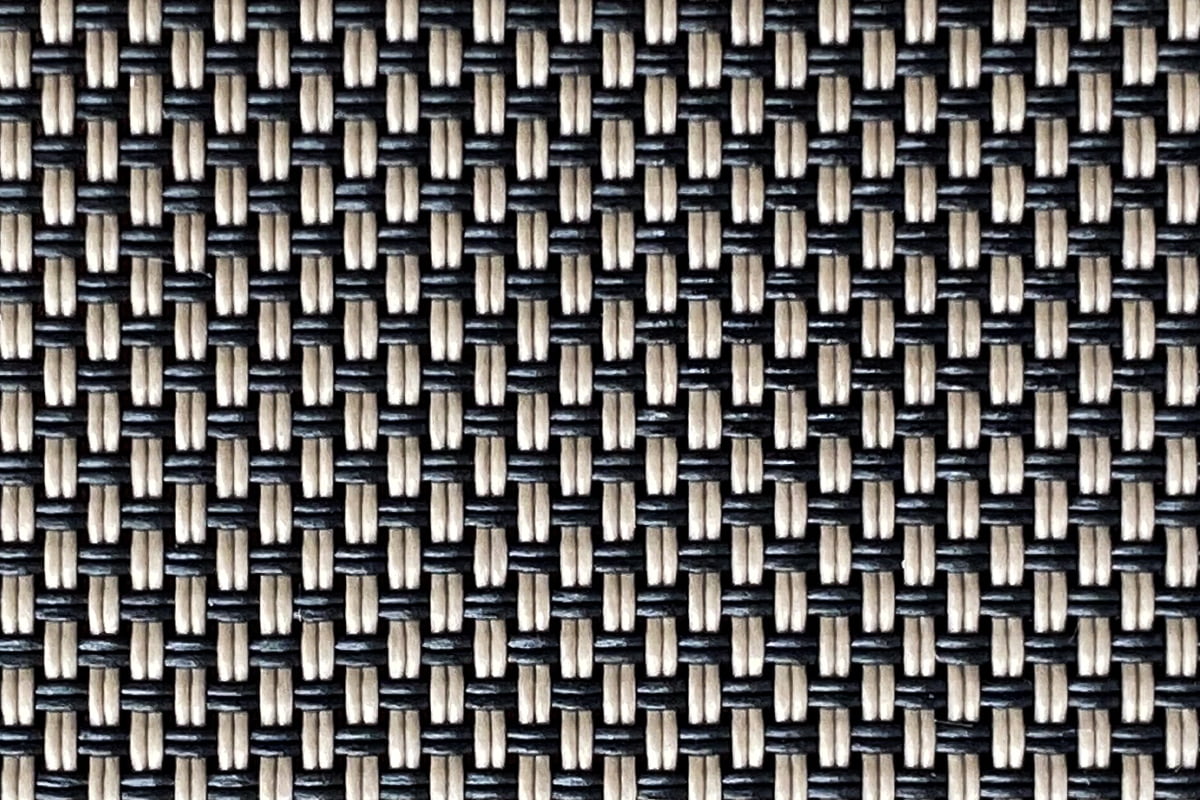

Seat belt webbing is typically made from high-strength polyester or nylon fibers woven together to provide durability, flexibility, and resistance to wear. The webbing must withstand high forces without tearing or elongating excessively. In addition to strength, it needs to retain its integrity over time, resisting degradation from UV exposure, heat, and repeated use.

Tensile Strength Testing

One of the primary tests for car seat belt webbing is tensile strength testing. Manufacturers place a sample of the webbing in a specialized testing machine that gradually applies force until the material breaks. This test measures the load the webbing can endure. The results are compared against safety standards to ensure the material can handle forces experienced in real-world collisions.

Elongation and Stretch Testing

In addition to strength, manufacturers assess how much the webbing stretches under load. Excessive elongation can reduce the effectiveness of the seat belt during sudden stops. By measuring elongation at different force levels, manufacturers can confirm that the webbing maintains its restraint capability without significant stretching. Controlled elasticity ensures comfort while still providing reliable protection.

Environmental and Aging Tests

Seat belt webbing is exposed to sunlight, heat, moisture, and chemicals throughout its life. To simulate long-term conditions, manufacturers conduct environmental aging tests. Webbing samples may be subjected to UV light, high temperatures, or chemical exposure to evaluate how these factors affect strength and flexibility. These tests help ensure that the webbing remains reliable over many years of use.

Abrasion and Wear Testing

Daily use can cause wear and abrasion to seat belt webbing, especially where it contacts buckles, hardware, or seat surfaces. Manufacturers perform abrasion tests by rubbing the webbing against standardized materials under controlled pressure for a set number of cycles. This simulates long-term wear and ensures that the webbing can withstand repeated use without fraying or weakening.

Compliance with Safety Standards

After testing, manufacturers verify that the seat belt webbing meets international and regional safety standards, such as FMVSS 209 in the United States or UNECE Regulation 16 in Europe. These standards define tensile strength, elongation limits, and other performance criteria. Compliance ensures that vehicles equipped with the webbing provide reliable occupant protection during collisions.

Quality Control and Batch Testing

In addition to laboratory testing, manufacturers implement ongoing quality control for production batches. Random samples from each batch are tested for strength, elasticity, and wear resistance to ensure consistent performance. This helps prevent defects and ensures that all seat belt webbing supplied to automakers meets the required safety standards.

Car seat belt webbing is tested rigorously to ensure it provides reliable protection for passengers. Tensile strength, elongation, environmental resistance, and abrasion tests all contribute to verifying durability and performance. By adhering to strict safety standards and implementing continuous quality control, manufacturers ensure that seat belt webbing can withstand real-world forces and maintain its protective function over time.

en

en Español

Español