Car safety relies on several components, with seat belts playing a crucial role in protecting passengers during sudden stops or collisions. At the heart of every seat belt is the Car Seat Belt Webbing, a strong woven material designed to absorb force and provide restraint. Understanding its design, manufacturing, and application is important for automotive manufacturers, repair shops, and safety regulators.

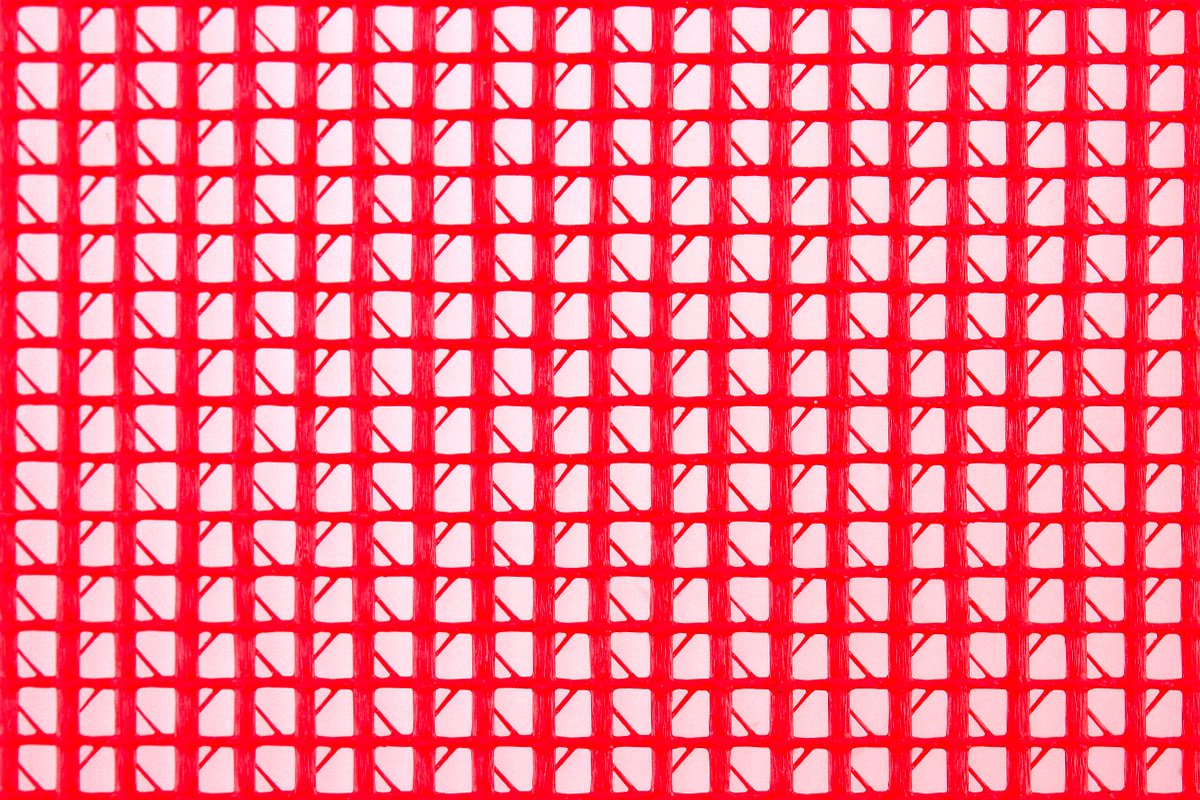

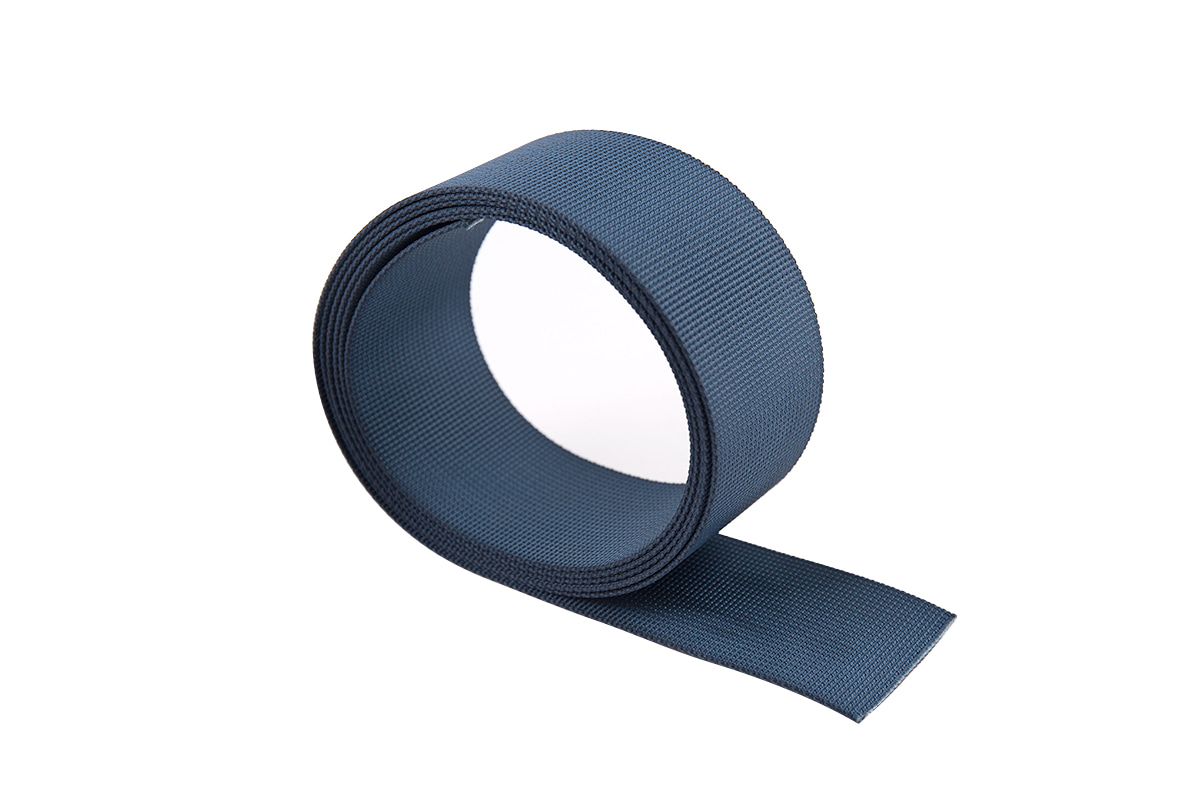

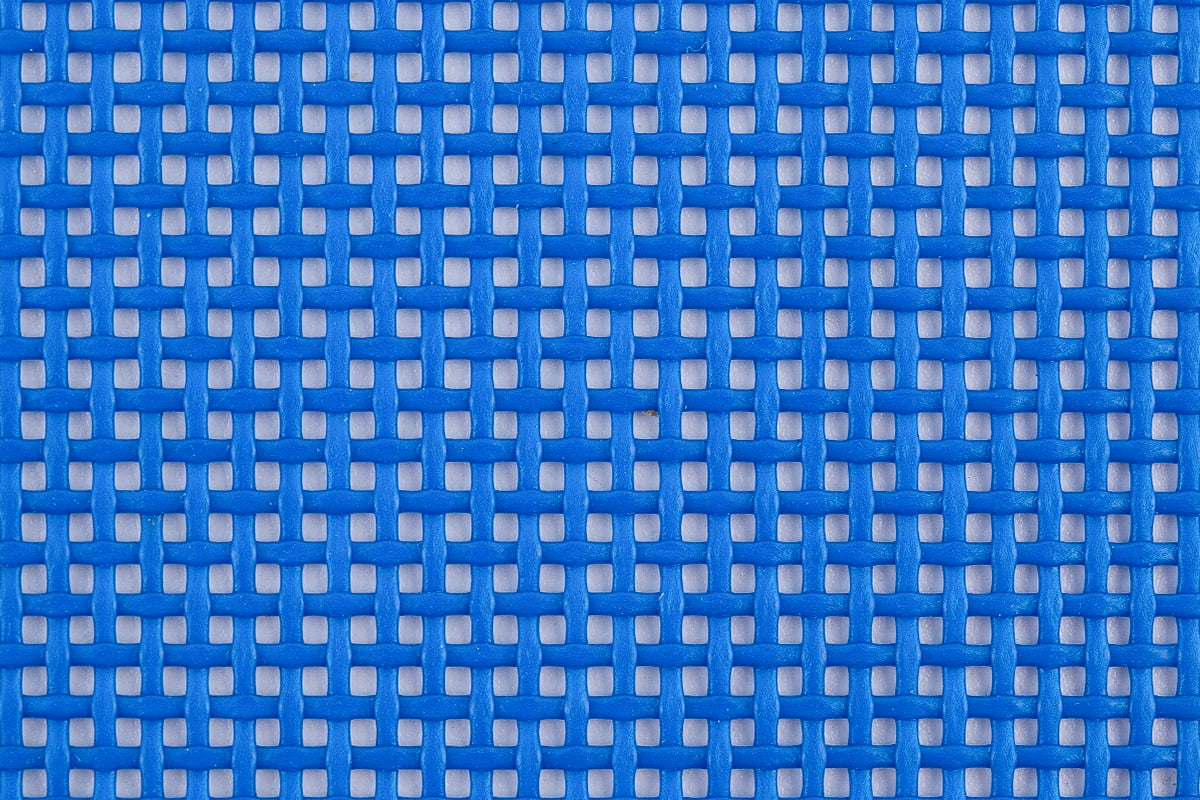

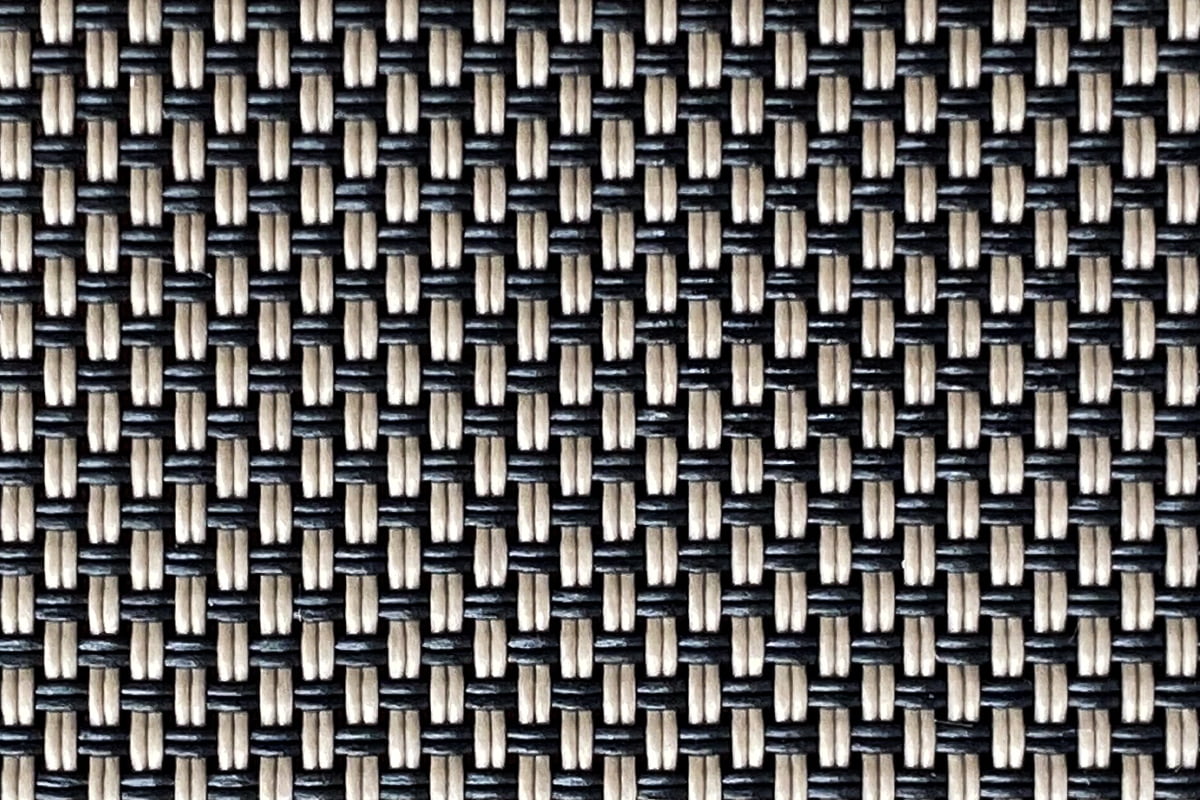

Car Seat Belt Webbing is a durable woven strap, usually made from polyester, nylon, or blended fibers. It is engineered to withstand significant tensile forces while remaining flexible enough for daily use. The weaving pattern, fiber quality, and finishing process all influence its strength, abrasion resistance, and longevity.

Webbing must pass rigorous testing to ensure it can handle the stresses of sudden deceleration, including controlled tensile tests and environmental exposure assessments.

Applications and Functionality

The primary function of Car Seat Belt Webbing is to restrain passengers safely during vehicle movement or accidents. It distributes the force of impact over the pelvis and chest, reducing injury risks. Beyond automotive use, similar webbing materials are sometimes applied in safety harnesses, child car seats, and industrial restraint systems, highlighting their versatility.

Proper installation is critical. Even high-quality webbing cannot provide protection if the belt is not anchored, routed, or locked correctly within the seat belt system. Automotive manufacturers often integrate webbing testing into assembly lines to maintain consistent safety standards.

Manufacturing Process

A Car Seat Belt Webbing factory typically follows a specialized process to ensure reliability. High-strength fibers are woven into flat straps using precise looms, producing a uniform thickness and pattern. Some webbings are dyed, treated with UV protection, or coated to improve abrasion resistance and durability.

Quality control is integrated at multiple stages. Visual inspections detect weaving defects, while tensile tests measure the breaking strength. Additional evaluations may include flame resistance, stretch tests, and chemical exposure resistance, ensuring the webbing performs under different conditions.

Selection Considerations

Choosing the right Car Seat Belt Webbing depends on several factors. Fiber composition, webbing width, thickness, and tensile strength should align with vehicle specifications and safety regulations. For replacement parts, compatibility with existing seat belt retractors and buckles is essential.

Environmental factors such as temperature, humidity, and exposure to sunlight are also important. Webbing designed for long-term durability must resist UV damage, moisture absorption, and wear from repeated use.

Maintenance and Inspection

Though designed for long-term use, Car Seat Belt Webbing requires periodic inspection. Visible fraying, cuts, or discoloration can indicate that the webbing's strength is compromised. Routine checks, especially after an accident or exposure to harsh conditions, are necessary to ensure continued safety.

Manufacturers provide guidelines for lifespan and replacement, helping vehicle owners and fleet operators maintain reliable restraint systems.

Supporting Vehicle Safety

Ultimately, Car Seat Belt Webbing is a critical component in passenger protection systems. Its strength, flexibility, and durability directly influence the effectiveness of seat belts. Automotive manufacturers, parts suppliers, and repair workshops all depend on high-quality webbing to meet safety standards and provide reliable performance for drivers and passengers.

By focusing on material quality, precise manufacturing, and rigorous testing, a Car Seat Belt Webbing factory ensures that every strap contributes to safer travel and peace of mind on the road.

en

en Español

Español