PVC mesh fabric is widely used in applications ranging from outdoor banners and tents to protective coverings and industrial nets. The role of a PVC Mesh Fabric Factory is to manufacture this versatile material efficiently while maintaining consistent quality, durability, and usability for various industries.

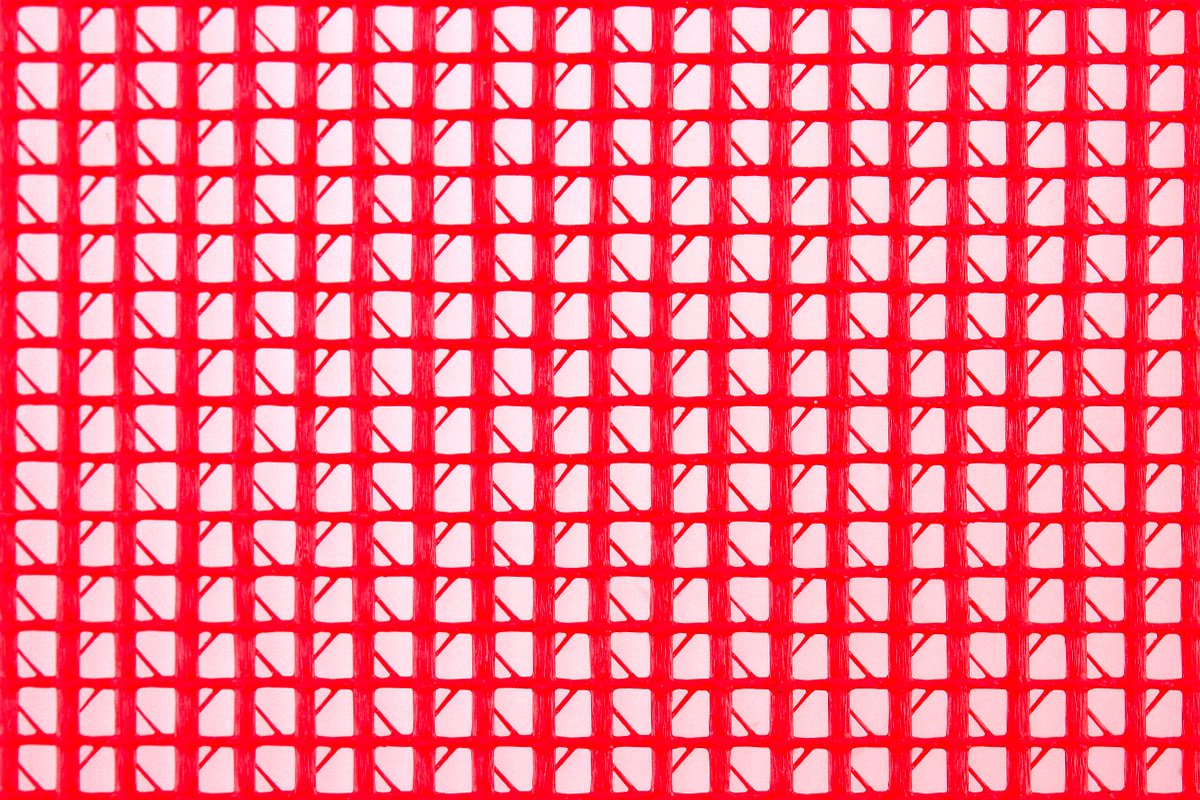

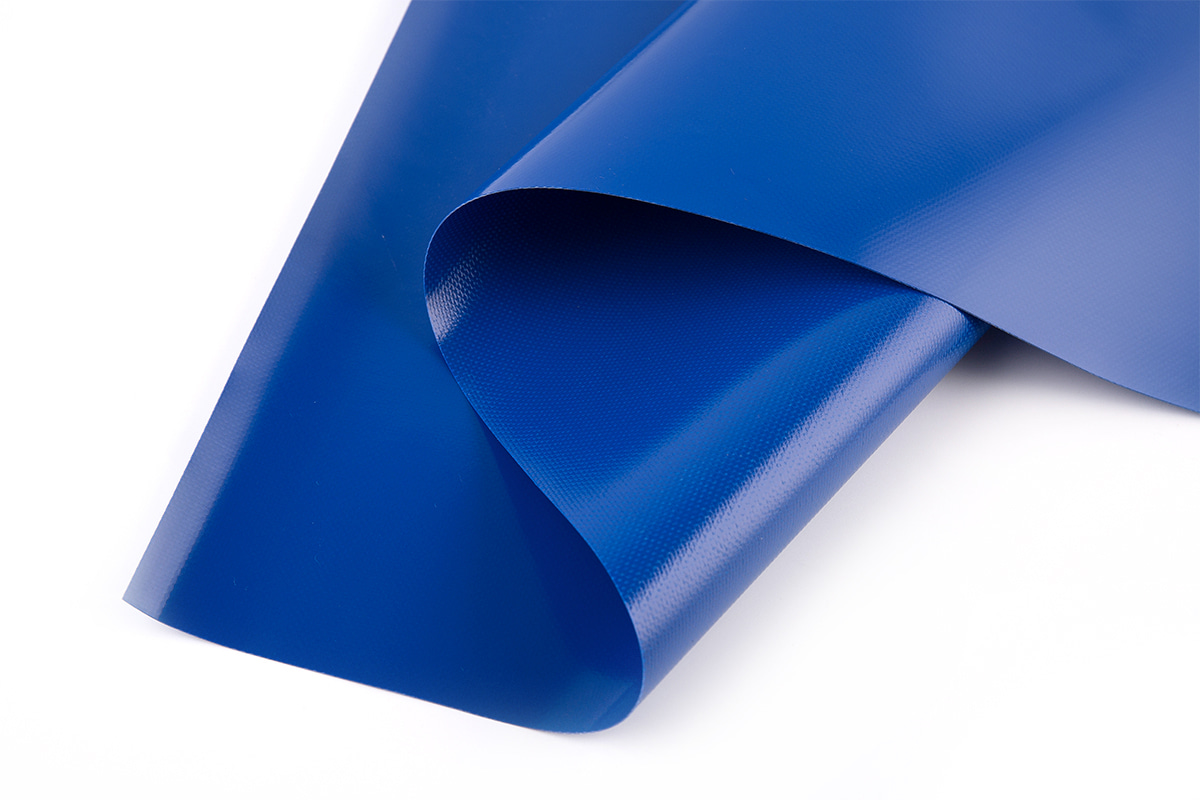

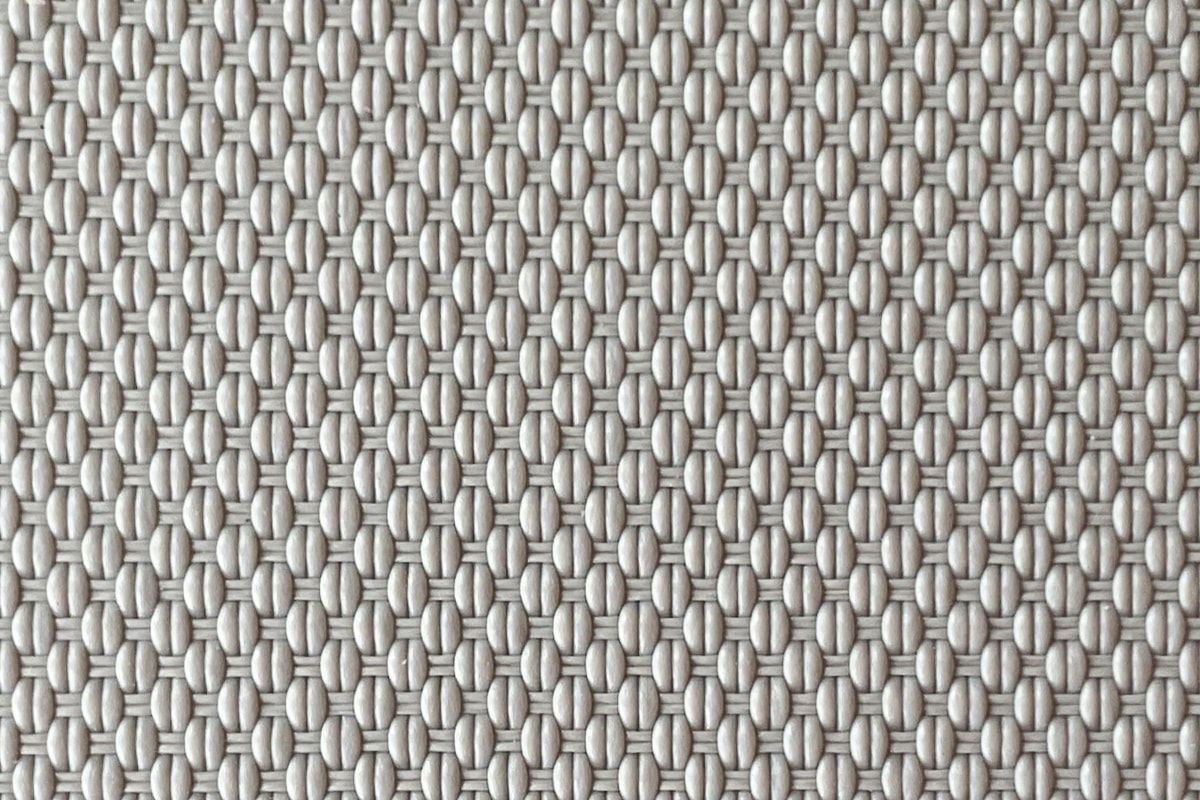

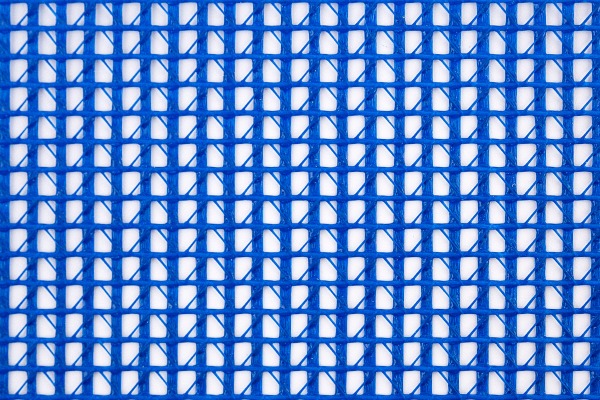

A PVC Mesh Fabric Factory specializes in producing woven or knitted mesh fabrics coated with polyvinyl chloride (PVC). The PVC coating provides water resistance, durability, and strength, while the mesh structure allows ventilation, light transmission, and flexibility. These properties make the fabric suitable for applications where durability and weather resistance are essential.

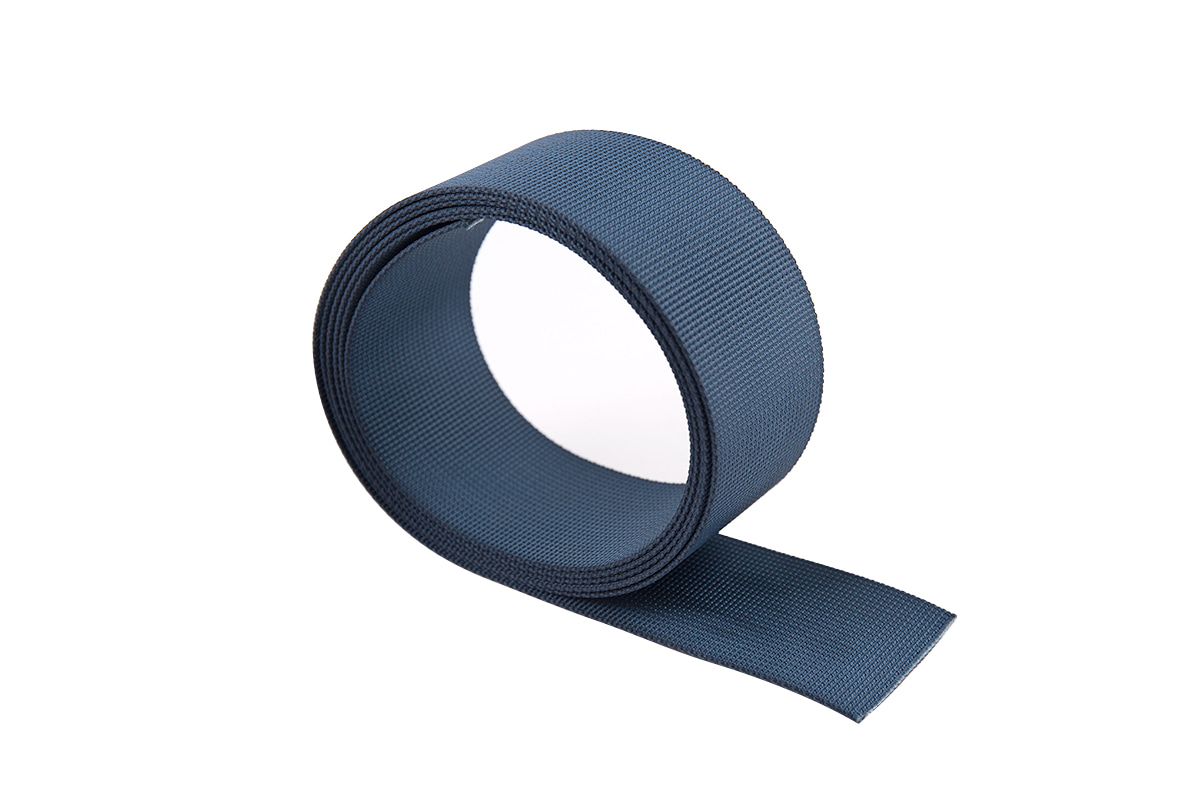

The production process begins with raw material preparation, usually polyester or polyethylene yarns. The yarns are woven into mesh using industrial looms, and then coated with PVC through calendaring, coating, or lamination processes depending on the fabric type and thickness requirements.

Key Production Considerations

Consistency in mesh size, coating thickness, and tensile strength is critical in a PVC Mesh Fabric Factory. Factories often implement rigorous quality control measures to ensure uniformity across large production batches. This includes monitoring the weaving tension, PVC coating application, and curing processes to maintain stability in dimensions and mechanical properties.

Color matching and finishing are also important. The factory may use color additives or surface treatments to ensure that each roll of fabric meets client specifications for visual appearance and functional performance.

Equipment and Technology

A modern PVC Mesh Fabric Factory relies on specialized machinery, including automatic weaving looms, coating lines, and curing ovens. Automated systems help maintain consistent production speed and reduce manual errors. For example, advanced coating machines apply PVC uniformly over the mesh while controlling temperature and pressure to prevent defects such as bubbles, wrinkles, or uneven thickness.

Automation also allows for flexibility in producing different mesh densities, fabric widths, and PVC formulations to meet the requirements of various industries.

Applications Across Industries

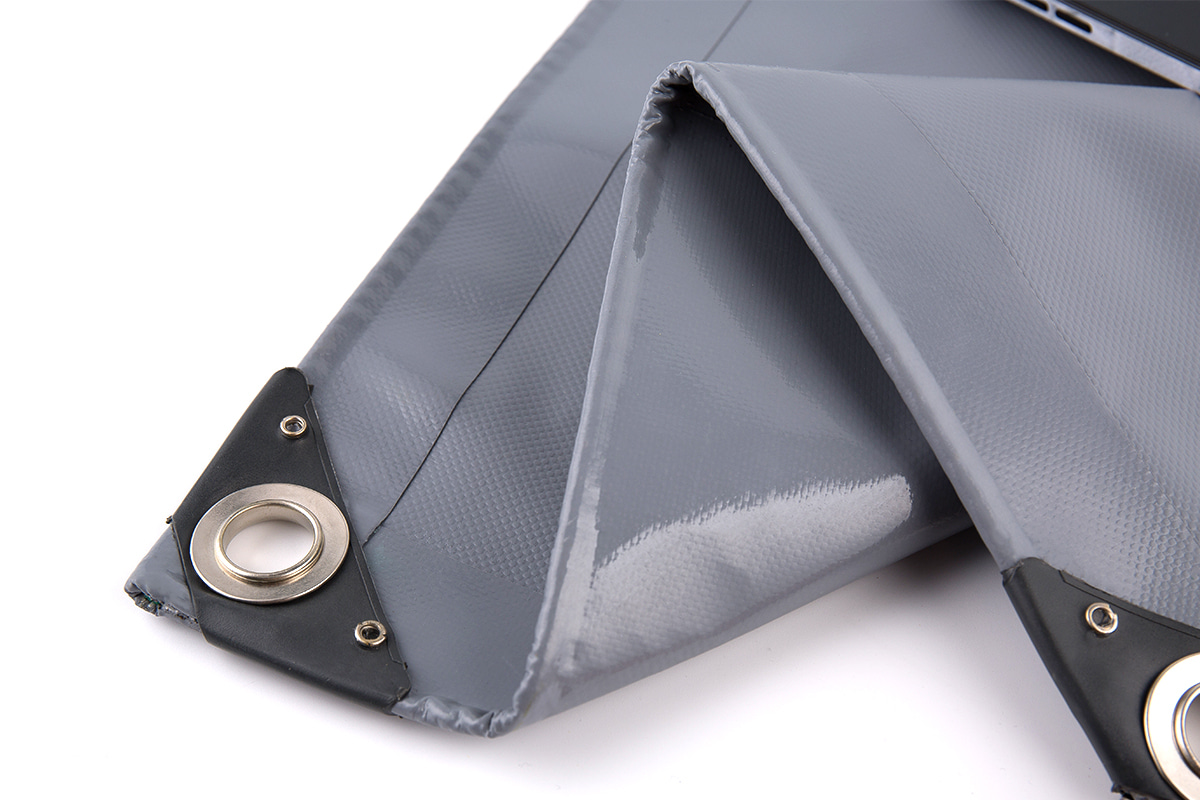

PVC mesh fabric produced by the factory finds use in multiple sectors. In construction, it is used for scaffolding nets, protective tarps, and sunshades. In advertising, it serves as durable outdoor banners and exhibition displays. Agriculture and horticulture industries utilize PVC mesh for plant protection and shading, while transportation and logistics industries use it for cargo covers and tent materials.

The versatility of the fabric requires the factory to adapt its production process according to different specifications, ensuring that each batch meets functional and aesthetic requirements.

Quality Control and Testing

A PVC Mesh Fabric Factory often integrates quality testing at several stages of production. Tensile strength, tear resistance, waterproofing, and UV resistance are commonly measured to ensure that the fabric can withstand intended usage conditions. Regular inspections reduce the likelihood of defects reaching customers and support long-term reliability.

Sustainability and Material Management

Many factories are adopting more sustainable practices, such as recycling production scraps or using eco-friendly PVC formulations. Efficient material management helps reduce waste and ensures that raw materials are used economically. This approach benefits both the factory and clients who prefer environmentally responsible suppliers.

A PVC Mesh Fabric Factory plays a crucial role in producing durable, functional, and versatile mesh fabrics for diverse industries. From weaving and PVC coating to finishing and quality control, each stage of production is designed to maintain consistency, strength, and usability. By combining advanced equipment, skilled labor, and careful process management, these factories deliver fabric that meets industrial and commercial demands, supporting projects that rely on reliable and durable mesh materials.

en

en Español

Español