Safety is a top concern for vehicle owners and manufacturers. Among the many safety components in a car, seat belts play a critical role. The fabric that forms the strap of a seat belt is called Car Seat Belt Webbing, and its quality directly impacts the effectiveness of the restraint system. This article explores what makes car seat belt webbing essential, how it is produced, and what factors to consider when selecting it for vehicles.

Understanding Car Seat Belt Webbing

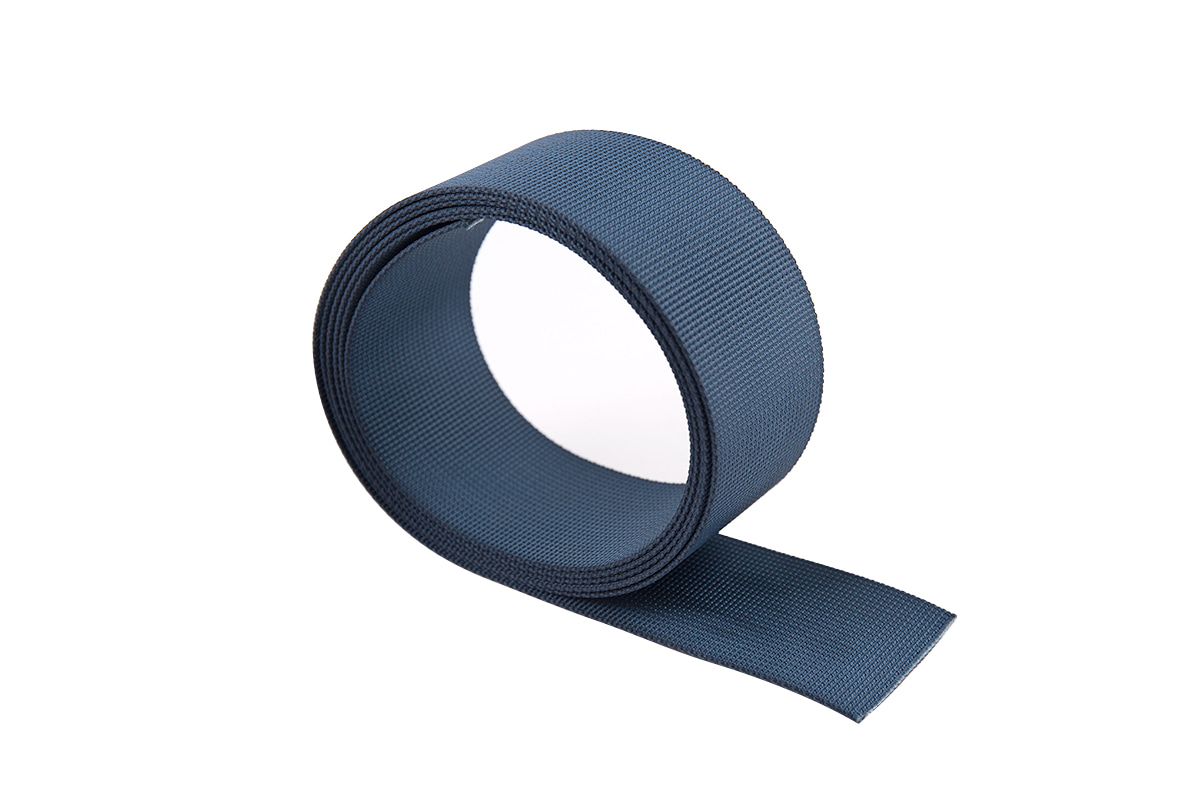

1. Material and Structure

Car seat belt webbing is typically made from polyester or nylon fibers. These materials are chosen for their strength, durability, and resistance to wear and stretching. The weaving technique also matters—tight, consistent weaving ensures that the webbing can handle sudden forces during a collision without tearing or deforming.

The webbing is more than just a strip of fabric. It has to resist abrasion from daily use, UV exposure from sunlight, and chemical exposure from cleaning products or sweat. A Car Seat Belt Webbing that loses integrity over time could fail to provide proper protection.

2. Safety Standards and Testing

Safety standards govern how car seat belt webbing should perform under stress. Factories producing this material often perform tests such as tensile strength measurement, elongation tests, and wear resistance checks. A Car Seat Belt Webbing that passes these tests ensures that it can restrain passengers safely during sudden stops or accidents.

Applications Beyond Regular Seat Belts

Although the main use of Car Seat Belt Webbing is in passenger vehicles, it is also applied in commercial vehicles, child car seats, racing harnesses, and even aircraft seating. Its versatility makes it a reliable material wherever passenger restraint is needed. The consistent quality and strength of webbing are what allow manufacturers to meet various regulatory requirements.

Factors to Consider When Choosing Car Seat Belt Webbing

1. Strength and Durability

The ability of the webbing to withstand high stress without stretching or breaking is essential. Consumers and manufacturers should check the tensile strength and the density of the weave.

2. Comfort and Flexibility

While safety is the priority, comfort is also important. Webbing should be flexible enough to retract smoothly but firm enough to hold passengers securely. A Car Seat Belt Webbing that is too stiff may cause discomfort, while one that is too loose may reduce safety.

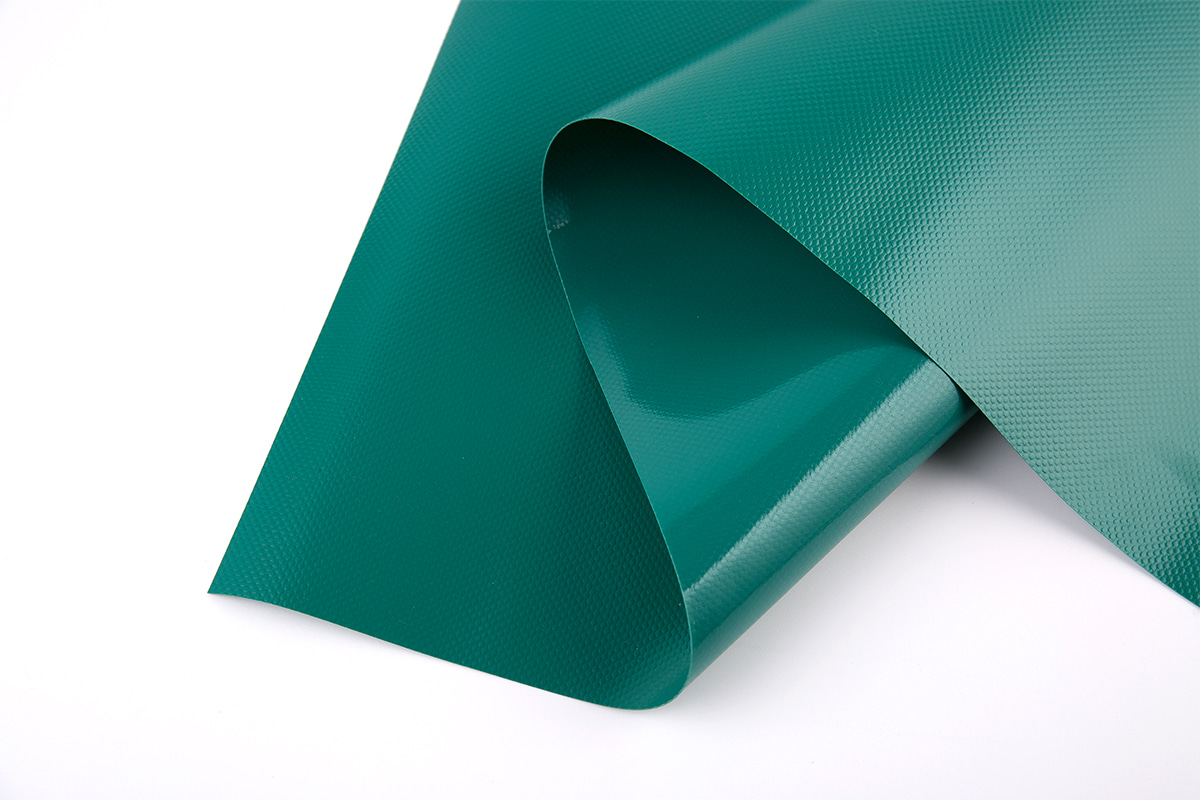

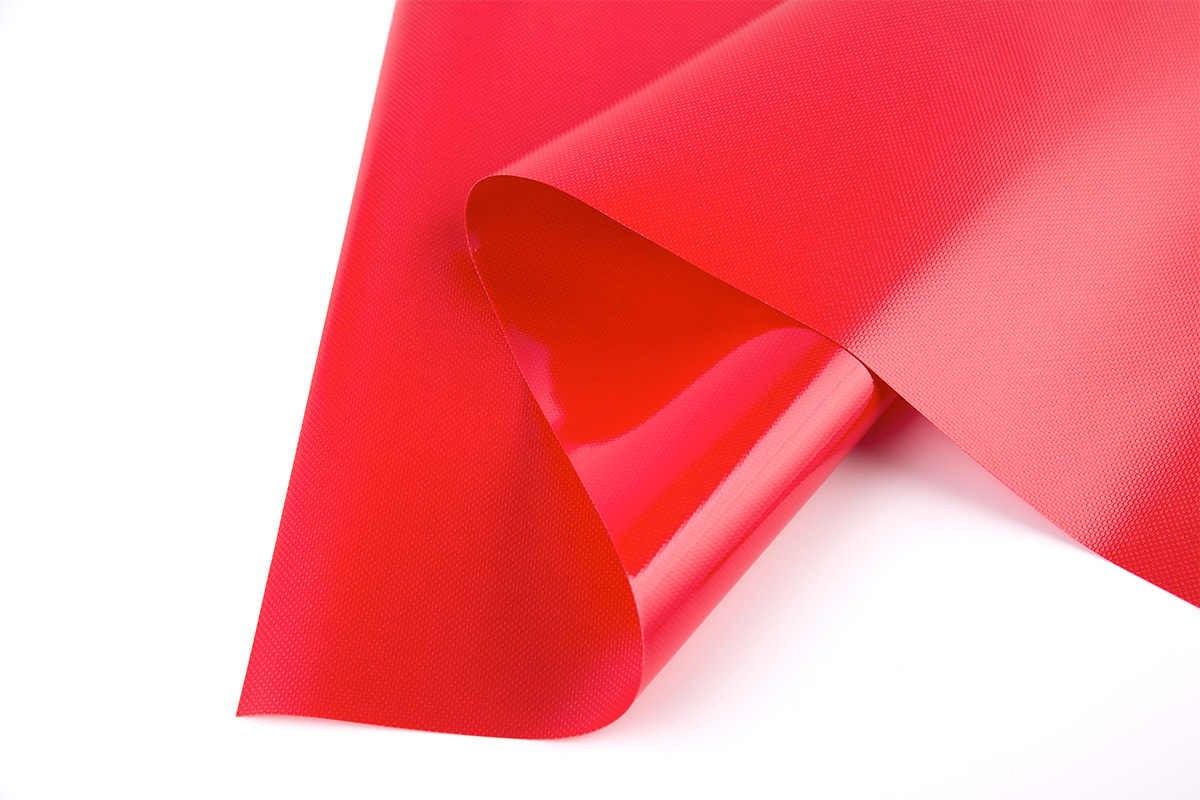

3. Color and Finish Options

Many manufacturers provide webbing in various colors and finishes to match car interiors. Though aesthetics may seem secondary, maintaining colorfastness and resistance to fading is part of the quality check.

Working with Reliable Suppliers

For automakers and aftermarket suppliers, finding a dependable Car Seat Belt Webbing source is important. A factory or supplier that follows consistent quality control practices ensures that every roll of webbing meets safety standards. Regular inspections and certifications can provide peace of mind for vehicle manufacturers and end-users.

Car Seat Belt Webbing is a critical component of automotive safety systems. Its strength, durability, and design directly affect passenger protection. By understanding its material properties, applications, and quality requirements, manufacturers and consumers can make informed choices. Reliable webbing not only supports safe driving but also contributes to the overall comfort and longevity of the seat belt system. For anyone involved in vehicle safety, investing in quality car seat belt webbing is a practical step toward safer roads.

en

en Español

Español