PVC mesh fabric has become a popular choice for a wide range of applications, from outdoor banners and tents to industrial filtration and packaging. Its versatility, durability, and lightweight structure make it an appealing material for both commercial and personal projects. Finding a reliable PVC Mesh Fabric Manufacturer is essential for ensuring consistent quality and supply.

1. Understanding PVC Mesh Fabric

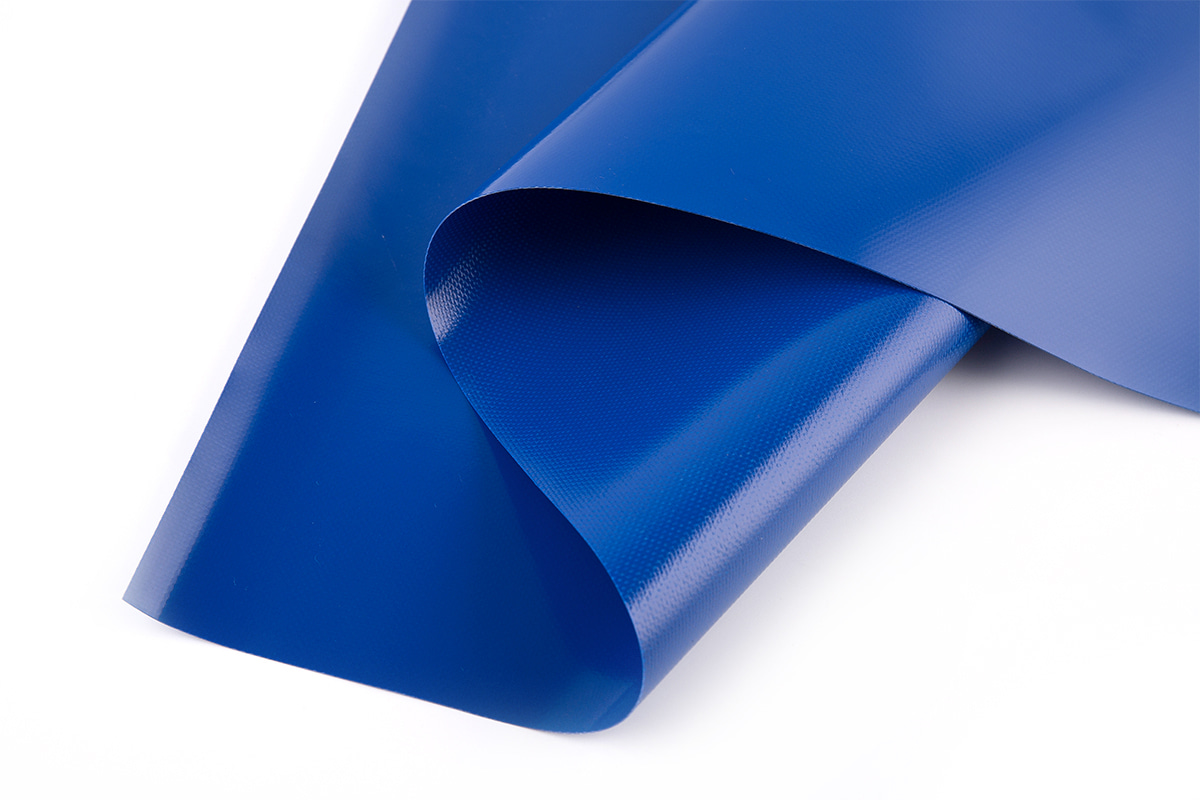

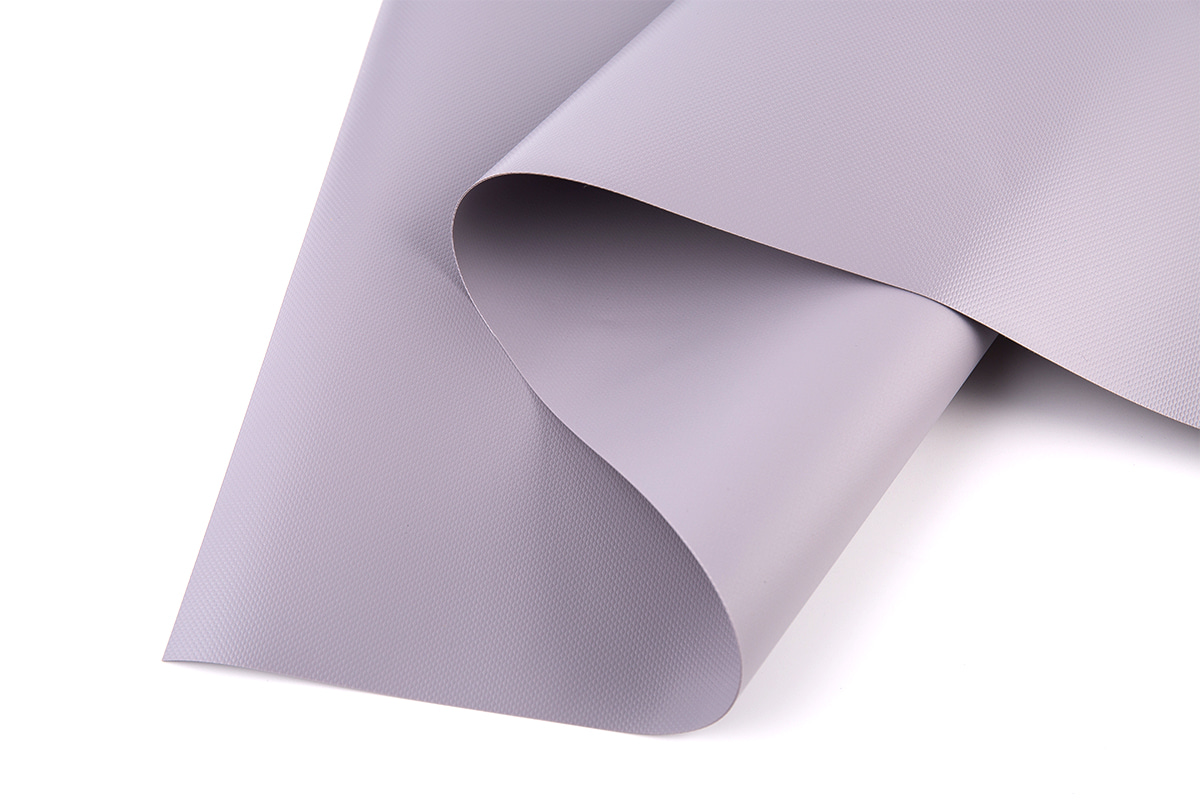

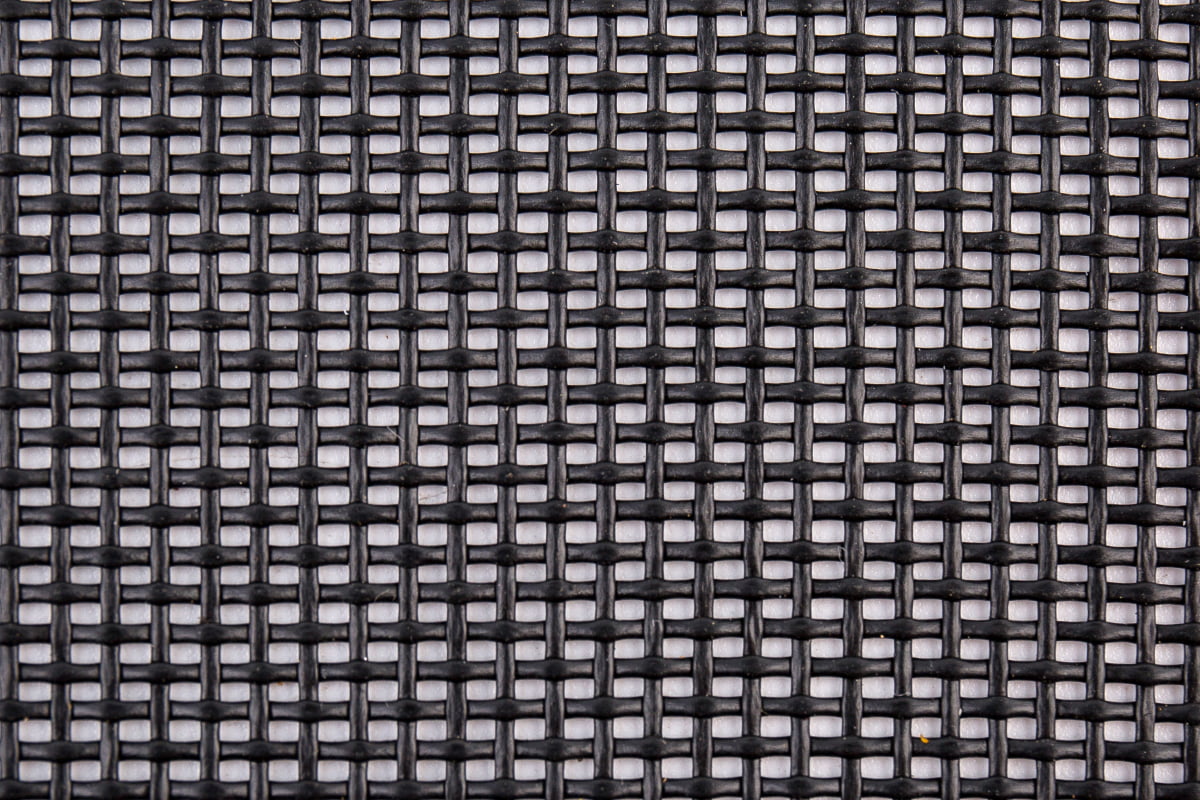

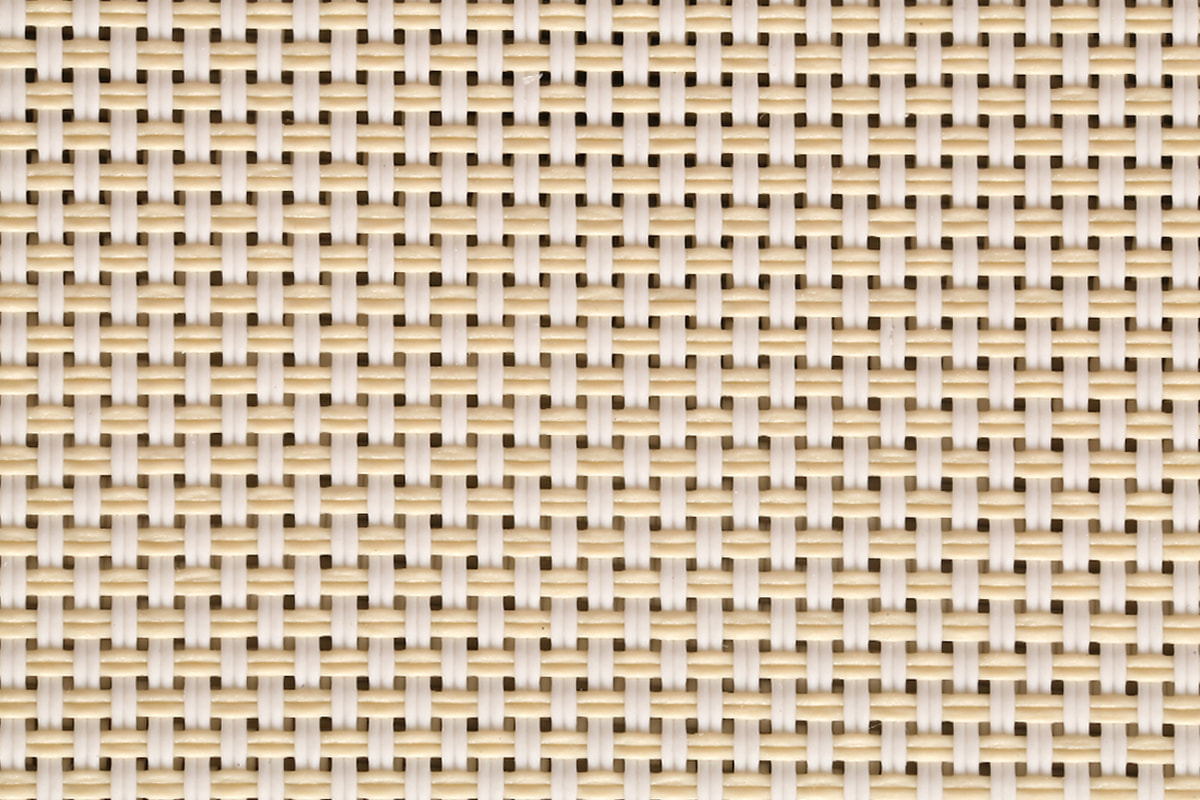

PVC mesh fabric combines the strength of woven materials with the flexibility of PVC coating. This structure gives it several useful properties:

- Durability: Resistant to wear, tear, and environmental conditions.

- Breathability: Mesh structure allows airflow, reducing moisture buildup.

- Lightweight: Easy to transport and handle in large quantities.

- Customizable: Can be produced in various thicknesses, colors, and patterns.

These qualities make PVC mesh fabric ideal for a variety of applications such as awnings, banners, agricultural covers, and even industrial curtains.

2. The Role of a PVC Mesh Fabric Manufacturer

A PVC Mesh Fabric Manufacturer is responsible for producing fabrics that meet precise quality standards and performance requirements. Their expertise impacts not only the durability of the material but also its usability in specific applications.

Key responsibilities include:

- Selecting appropriate PVC coatings and woven fibers

- Maintaining consistent weaving density and coating thickness

- Ensuring color stability and resistance to UV or weather conditions

- Providing custom sizes, patterns, or reinforced fabrics according to client needs

Working with an experienced manufacturer ensures the end product performs as expected and minimizes the risk of defects or inconsistencies.

3. Benefits of Choosing the Right Manufacturer

Partnering with the right PVC Mesh Fabric Manufacturer brings practical advantages:

- Reliable Supply: Steady production and inventory help meet project timelines.

- Technical Support: Guidance on suitable fabric types and treatments for specific applications.

- Quality Assurance: Regular inspection and testing maintain fabric performance.

- Customization Options: Ability to produce fabrics tailored to color, size, and coating specifications.

These factors make it easier for businesses to integrate PVC mesh fabric into their products or operations without worrying about material failure or delays.

4. Common Applications of PVC Mesh Fabric

PVC mesh fabrics are used in a variety of industries. Some common applications include:

- Outdoor advertising: Durable banners and signs that withstand weather conditions.

- Agriculture: Shade nets and greenhouse coverings.

- Industrial use: Partition walls, filtration materials, or safety covers.

- Consumer products: Tent walls, backpacks, and protective covers.

By choosing a knowledgeable PVC Mesh Fabric Manufacturer, you can select materials that suit your exact project requirements and longevity expectations.

5. Tips for Working With a Manufacturer

When sourcing PVC mesh fabric, consider the following tips:

- Check for certifications and quality standards

- Request fabric samples before bulk orders

- Discuss UV, waterproofing, or fire-retardant options if needed

- Maintain clear communication about delivery schedules and customization

- Build a long-term relationship for consistent supply

These steps help ensure your projects proceed smoothly with high-quality material.

A PVC Mesh Fabric Manufacturer plays a crucial role in delivering consistent, durable, and customizable materials for various industries. By carefully selecting a reliable manufacturer, businesses and individuals can benefit from both product quality and dependable supply. Whether you are producing banners, tents, or industrial fabrics, working with a skilled manufacturer helps achieve smoother, long-lasting results.

en

en Español

Español