PVC mesh fabrics are widely used in outdoor applications, from shade structures and banners to protective covers and tents. Their popularity comes from their durability, flexibility, and ability to handle harsh environments. For businesses and end-users, understanding how PVC mesh fabrics resist weathering and maintain performance is essential. PVC Mesh Fabric Factories design and test these materials to ensure they can withstand outdoor conditions while retaining strength and appearance.

Material Composition

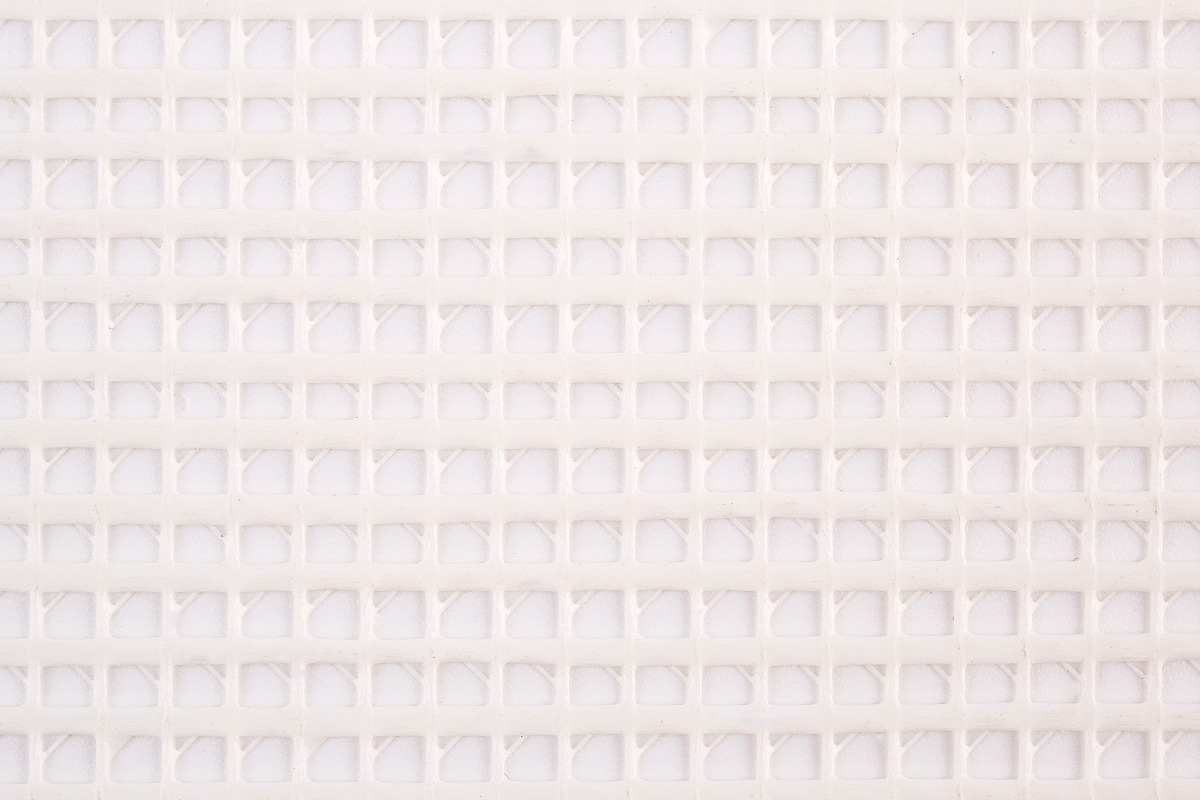

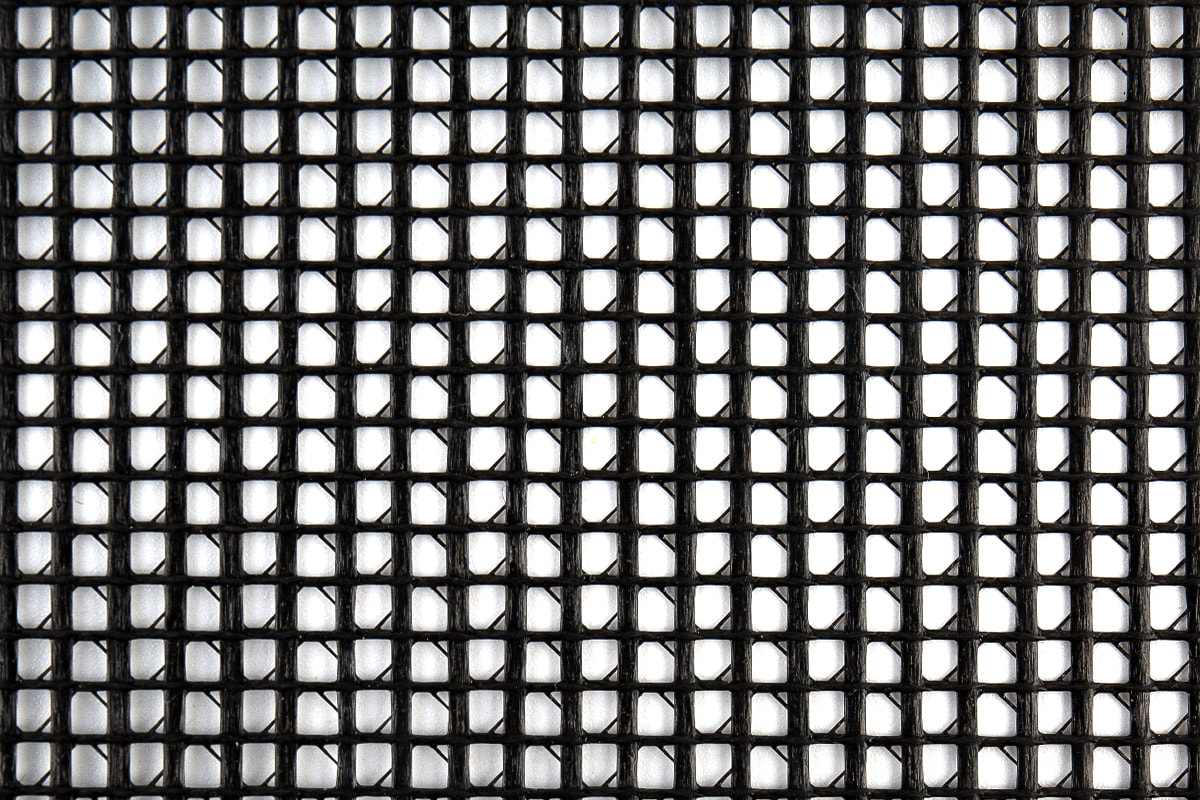

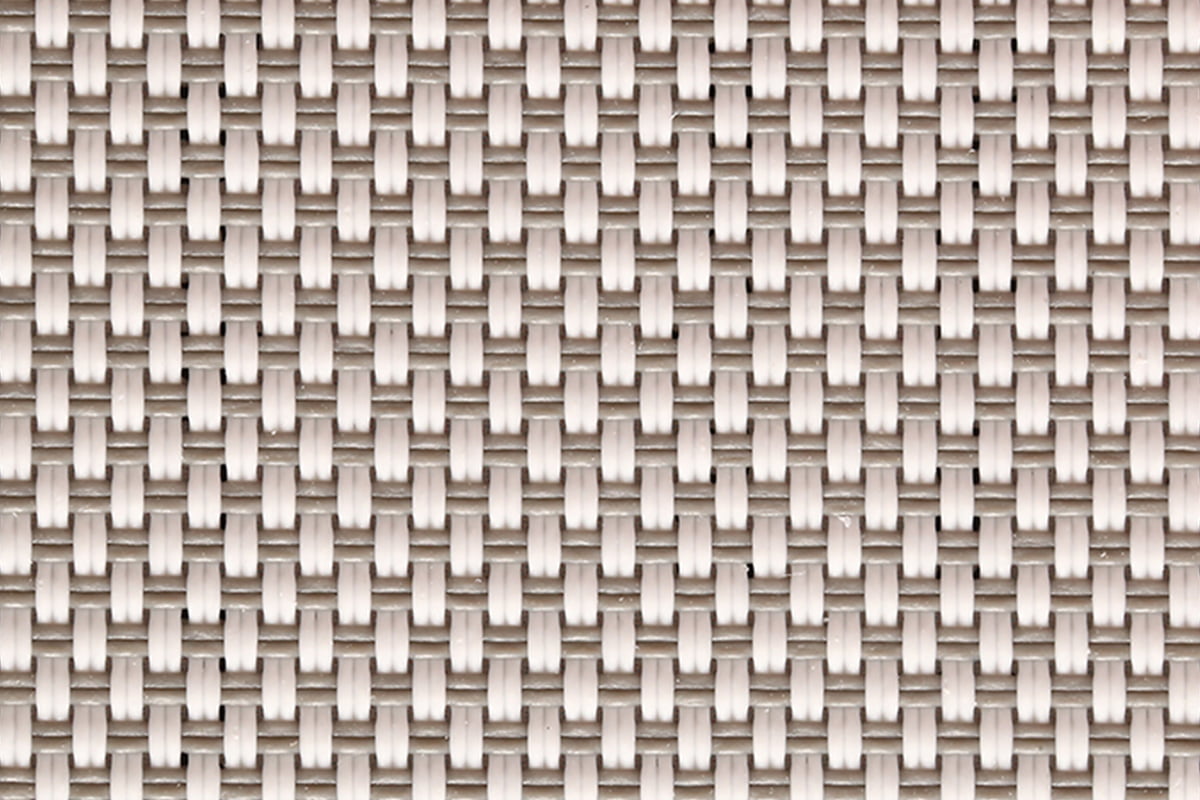

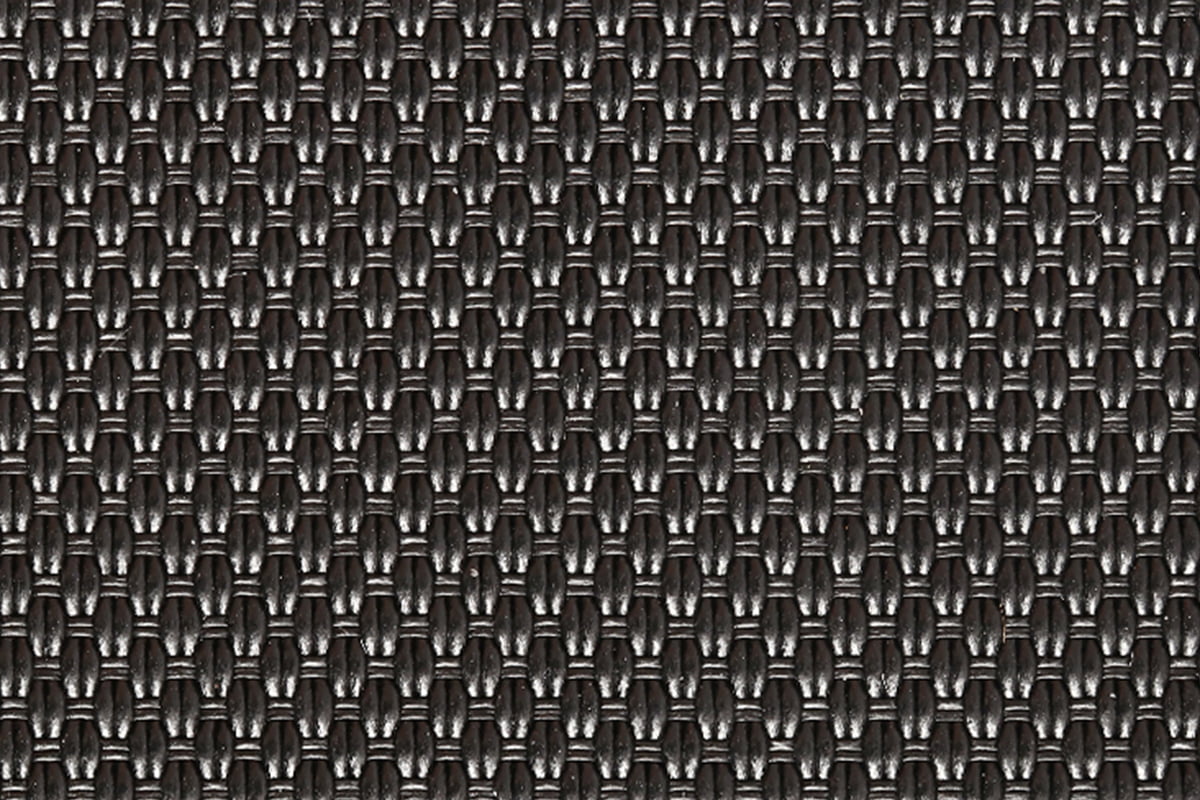

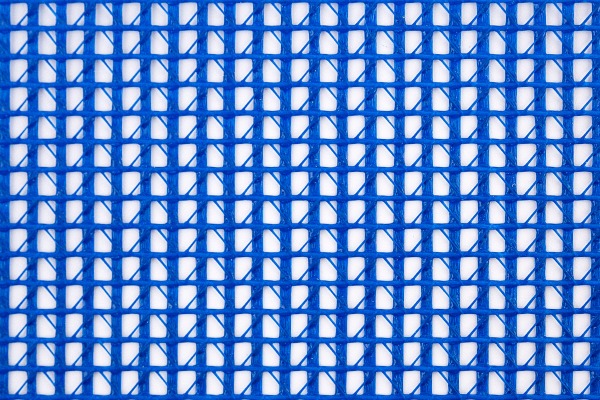

The resilience of PVC mesh fabrics begins with their composition. These fabrics are made by coating a woven polyester or polyethylene base with a layer of PVC (polyvinyl chloride). The PVC coating provides water resistance, UV protection, and flexibility, while the woven core ensures tensile strength and shape retention. PVC Mesh Fabric Factories carefully select high-quality polymers and weave patterns to create fabrics capable of enduring extended exposure to sun, rain, and wind.

UV Resistance

Sunlight can be particularly damaging to outdoor materials, cause to fading, brittleness, and structural degradation. PVC mesh fabrics are treated with UV stabilizers during manufacturing to minimize the effects of prolonged exposure. This treatment allows the fabric to maintain its color and strength over time. Manufacturers test samples under simulated sunlight to measure how well the fabric resists fading and cracking, ensuring the finished product remains functional and visually appealing for outdoor use.

Water and Moisture Resistance

Outdoor fabrics must also resist water and moisture. The PVC coating on mesh fabrics acts as a barrier against rain, humidity, and condensation. Unlike untreated fabrics, PVC mesh does not absorb water, preventing mold, mildew, and material weakening. PVC Mesh Fabric Factories often perform water spray tests or immersion trials to ensure that the fabric maintains integrity and does not degrade when exposed to wet conditions. Proper drainage and breathable weaving patterns further enhance durability in outdoor settings.

Strength and Wind Resistance

Another key consideration for outdoor applications is mechanical strength. PVC mesh fabrics are designed to withstand wind pressure and tension without tearing. The woven structure, combined with the PVC coating, distributes stress evenly across the fabric. Factories conduct tensile and tear resistance tests to verify that the material can endure repeated stress. These tests ensure that the fabric will hold up on banners, tents, and shade structures even in challenging weather conditions.

Maintenance and Longevity

While PVC mesh fabrics are durable, proper maintenance helps extend their lifespan. Regular cleaning with mild soap and water, avoiding harsh chemicals, and storing the fabric properly during off-season periods can prevent premature wear. PVC Mesh Fabric Factories provide guidance on care practices to maintain both performance and appearance. Following these recommendations ensures that the fabrics continue to resist UV, water, and mechanical stress effectively over time.

PVC mesh fabrics are engineered to endure the challenges of outdoor conditions through a combination of durable materials, UV resistance, water repellence, and mechanical strength. PVC Mesh Fabric Factories test these fabrics thoroughly to confirm their performance and longevity. With proper selection and care, PVC mesh fabrics can maintain their functionality, appearance, and reliability even in harsh environments, making them a practical choice for a wide range of outdoor applications.

en

en Español

Español