Vinyl woven mesh fabric has become increasingly popular across industries due to its strength, durability, and adaptability. Whether used in furniture, outdoor shading, or industrial applications, this material offers practical benefits that make it suitable for diverse needs. Understanding its properties, manufacturing process, and applications can help buyers, designers, and manufacturers make informed decisions.

Material Composition and Construction

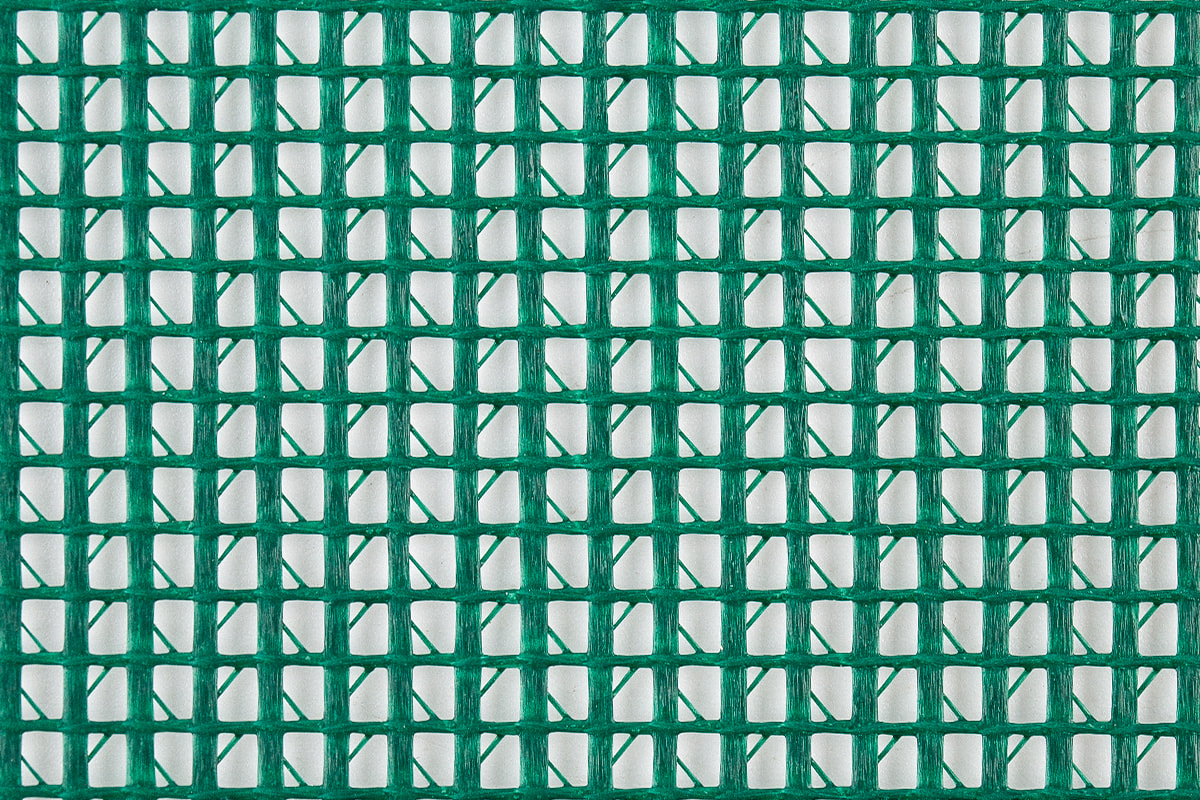

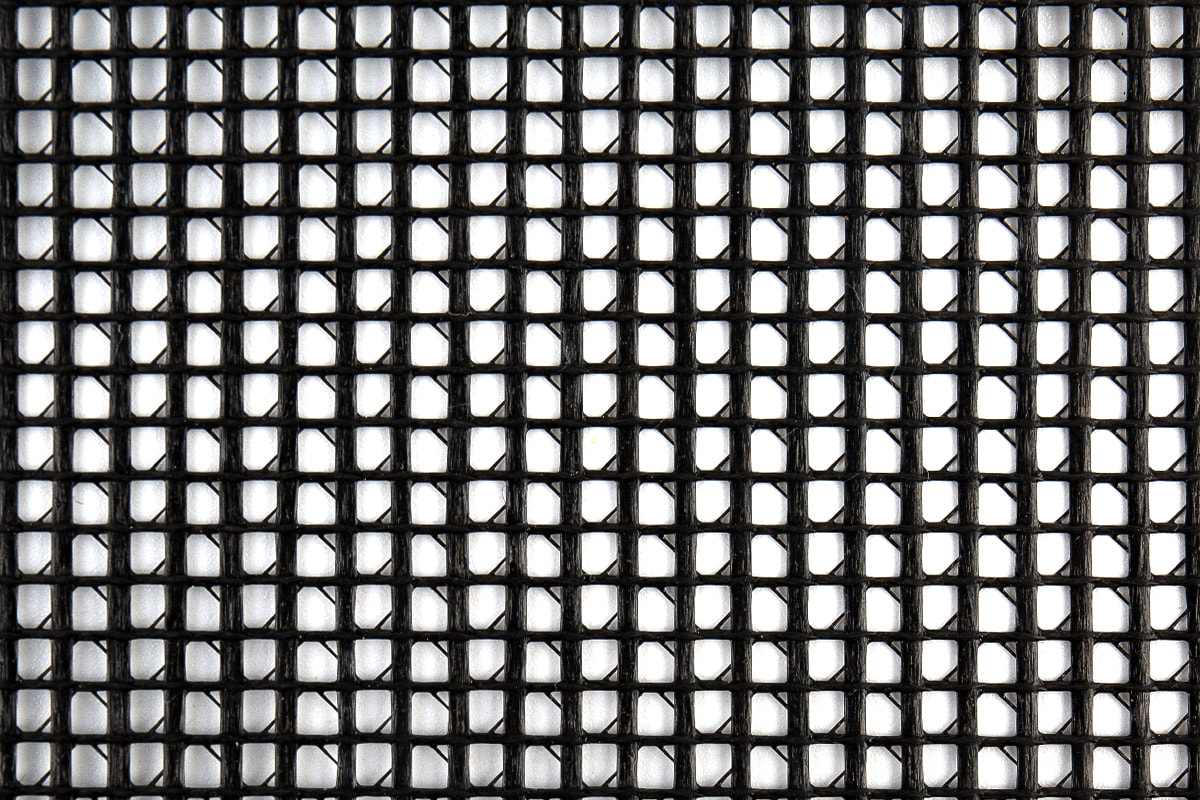

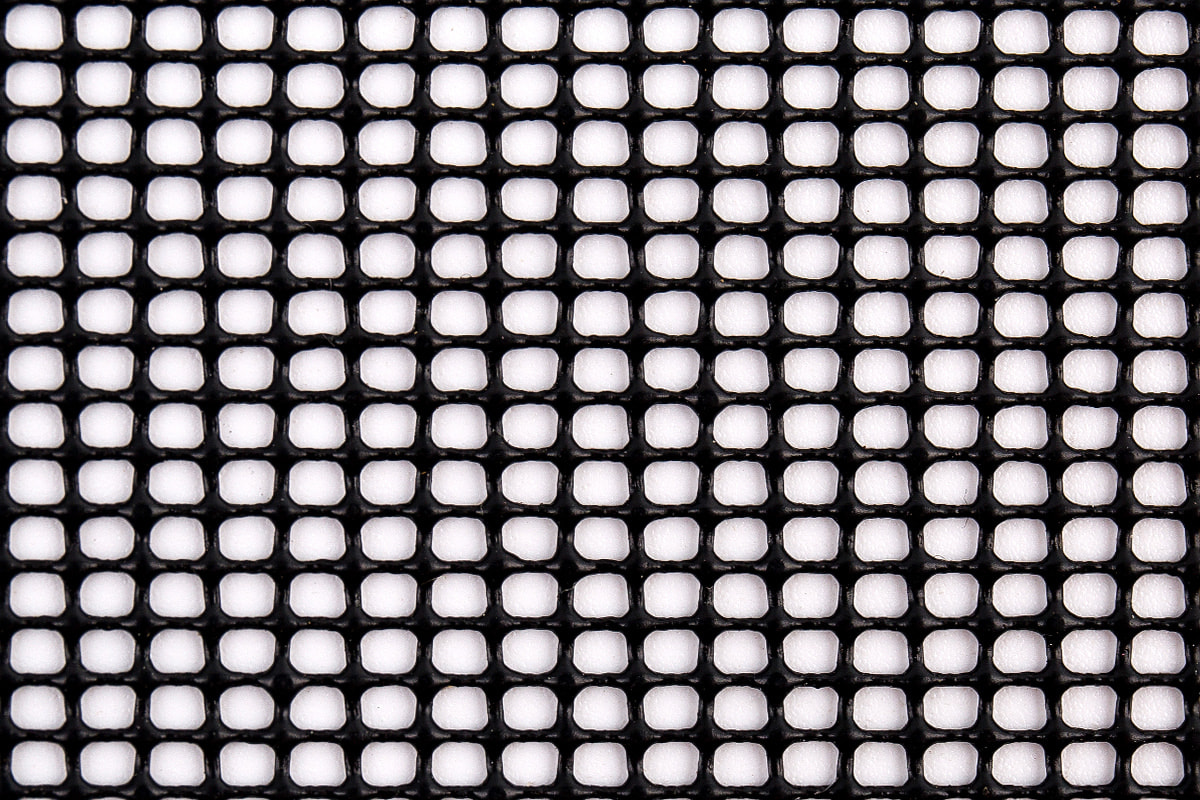

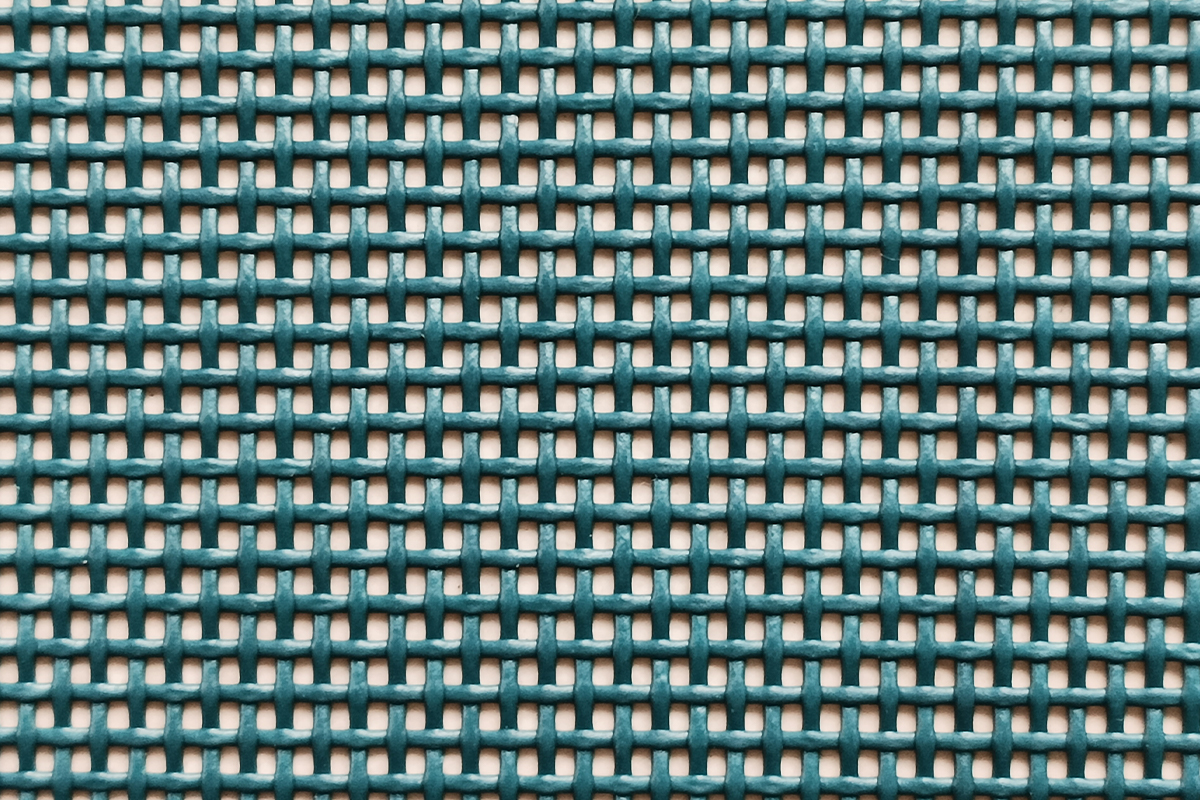

At its core, vinyl woven mesh fabric is made by weaving synthetic fibers, typically polyester or PVC-coated yarns, into a grid-like structure and then coating them with vinyl. This combination provides a balance of strength, flexibility, and weather resistance. The woven design allows for breathability, which is particularly useful in outdoor or high-temperature environments. The vinyl coating adds an extra layer of protection against moisture, mold, and fading caused by sunlight.

Different weaving patterns and coating thicknesses affect the fabric's performance. For example, tighter weaves improve structural integrity, while looser weaves increase airflow and comfort. Understanding these differences helps users select the right fabric for specific applications.

Common Applications

A vinyl woven mesh fabric is widely used in furniture, especially for chairs, loungers, and sunbeds. Its breathable nature allows for comfort in hot weather, while the vinyl coating ensures easy cleaning and resistance to stains. Outdoor furniture designers often favor this material because it maintains its shape and color even under frequent exposure to sunlight and moisture.

Beyond furniture, vinyl woven mesh fabric finds applications in industrial settings, such as conveyor belts, safety screens, and protective covers. Its durability and resistance to tearing make it suitable for repeated use, while its flexibility allows it to adapt to various shapes and sizes. Some manufacturers also produce mesh fabric for sports equipment, tents, and awnings.

Advantages of Vinyl Woven Mesh Fabric

One of the main benefits of vinyl woven mesh fabric is its combination of strength and breathability. Unlike solid plastic or metal materials, the mesh structure allows air circulation, reducing heat buildup. The vinyl coating adds resistance to water, mildew, and UV damage, prolonging the material's life in outdoor applications. Maintenance is relatively easy; dirt or stains can be wiped off with mild soap and water, making it practical for everyday use.

Durability and Maintenance

Durability is a key factor when selecting vinyl woven mesh fabric. The woven structure combined with vinyl coating provides resistance to stretching, tearing, and environmental stress. Over time, proper care, such as avoiding harsh chemical cleaners or sharp objects, helps maintain the fabric's appearance and performance. Some industrial applications may also require periodic inspection to ensure the mesh remains intact and functional.

Sustainability Considerations

As sustainability becomes more important, some manufacturers are exploring recyclable or environmentally friendly versions of vinyl woven mesh fabric. Reusing or recycling the material reduces waste and minimizes environmental impact. Buyers who prioritize eco-conscious sourcing may want to verify the manufacturer's production practices and material composition.

Vinyl woven mesh fabric is a versatile and practical material suitable for furniture, outdoor, and industrial applications. Its combination of strength, breathability, and weather resistance makes it valuable for a wide range of uses. By understanding its composition, advantages, durability, and maintenance requirements, buyers can make informed choices that suit their specific needs. Selecting the right vinyl woven mesh fabric ensures lasting performance, aesthetic appeal, and functional efficiency across different settings.

en

en Español

Español