Solar Screen Mesh Fabric has become an essential component in building construction, offering heat reduction, glare control, and UV protection. Behind every roll of this fabric is a structured manufacturing process that ensures consistent quality, durability, and performance.

Raw Materials and Selection

The production of Solar Screen Mesh Fabric begins with careful selection of raw materials. factories use fiberglass, polyester, or PVC-coated polyester fibers for their strength, flexibility, and resistance to UV exposure. Fiberglass offers high dimensional stability, while polyester adds toughness and flexibility. Some manufacturers add coatings to enhance durability, reduce static, or provide water and weather resistance.

The choice of material directly impacts the fabric's tensile strength, longevity, and effectiveness in blocking heat and sunlight, making it a critical step in manufacturing.

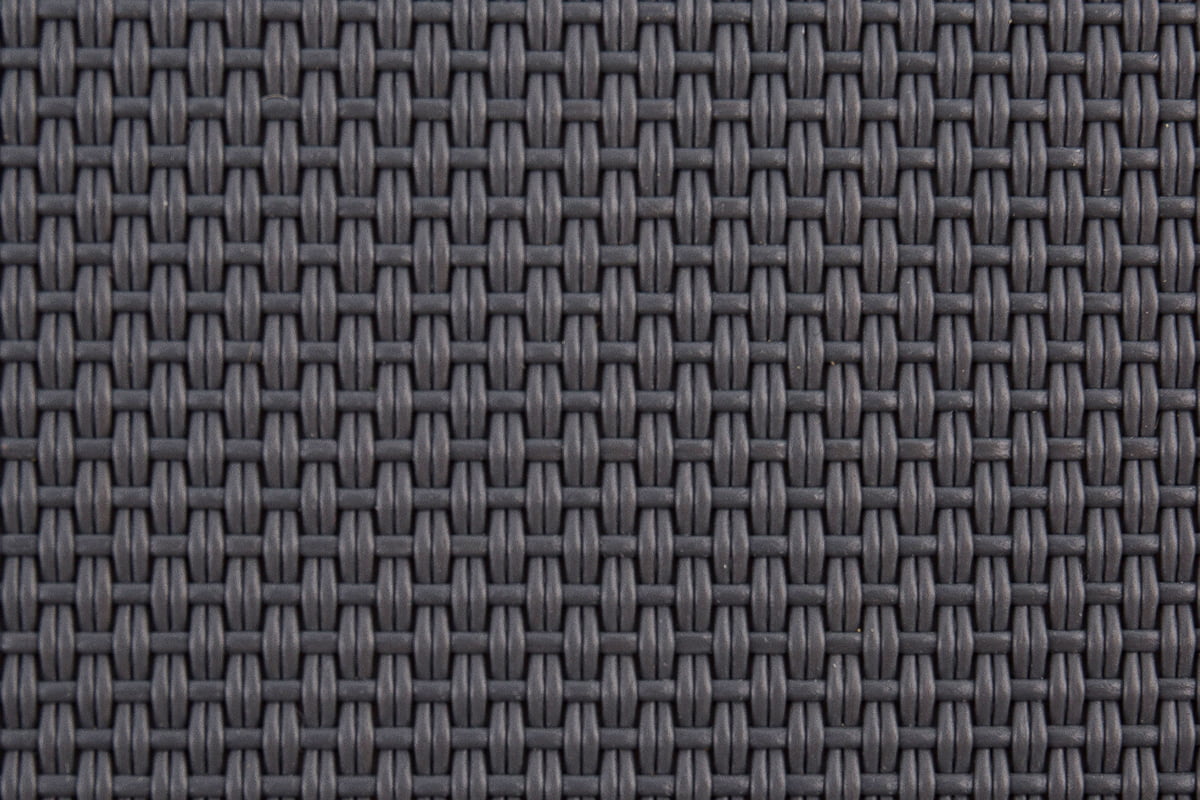

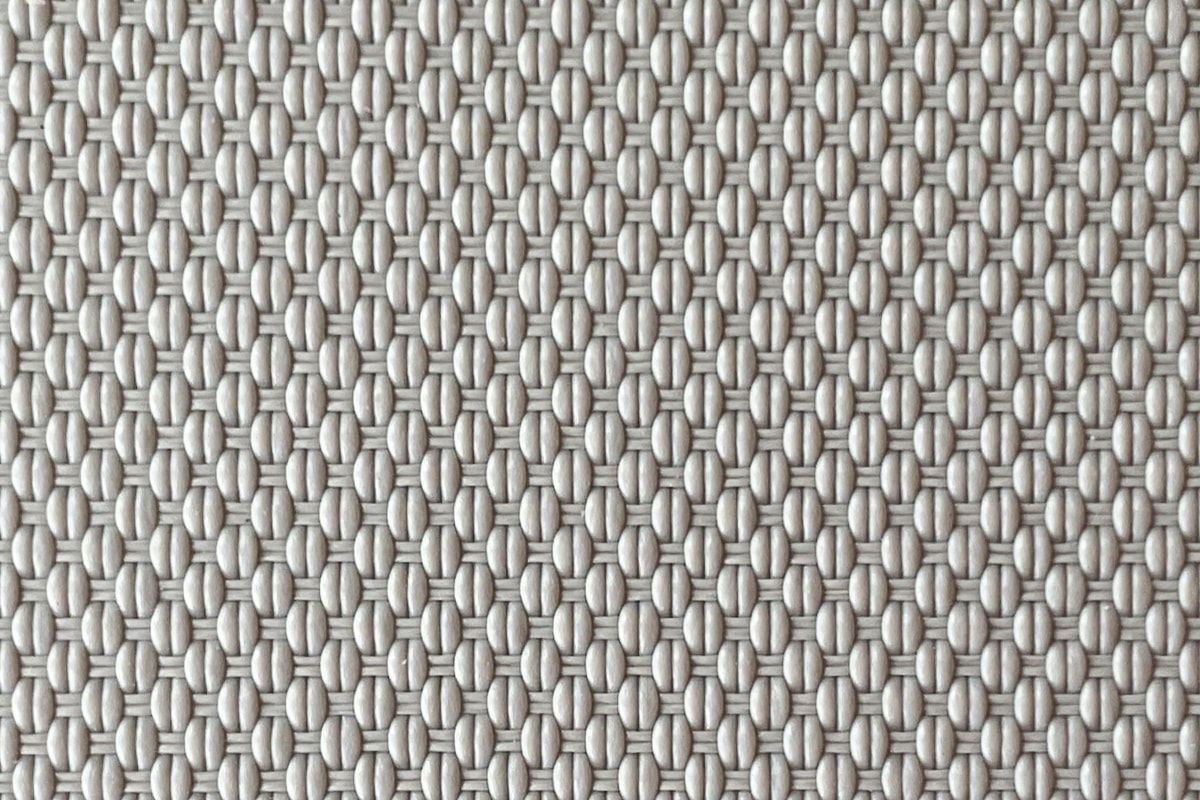

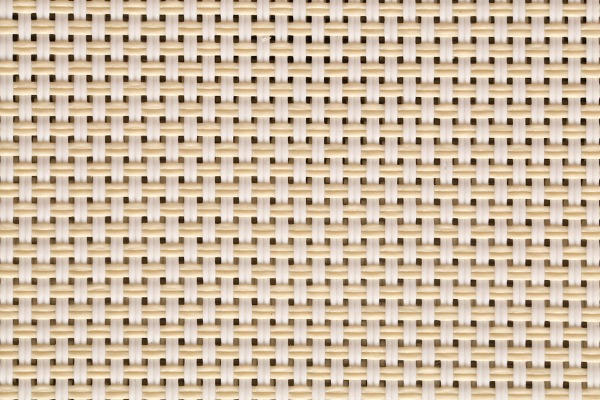

Weaving and Fabric Formation

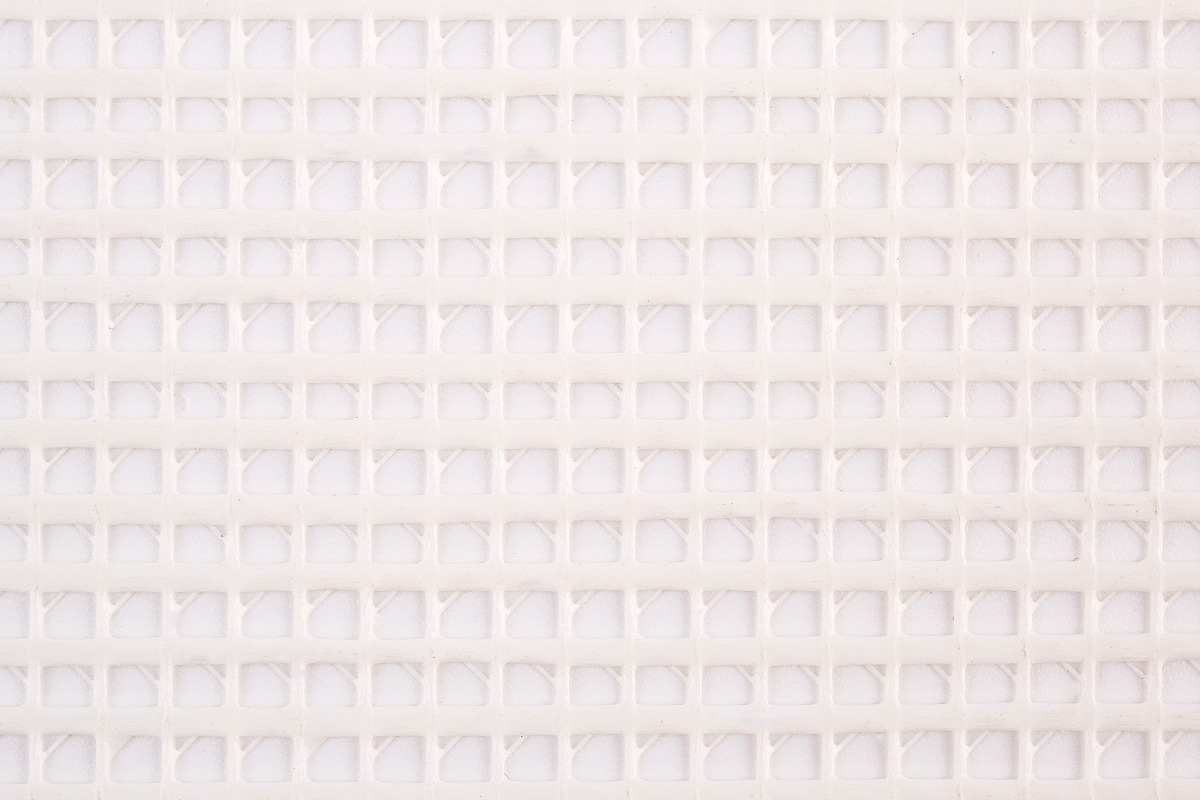

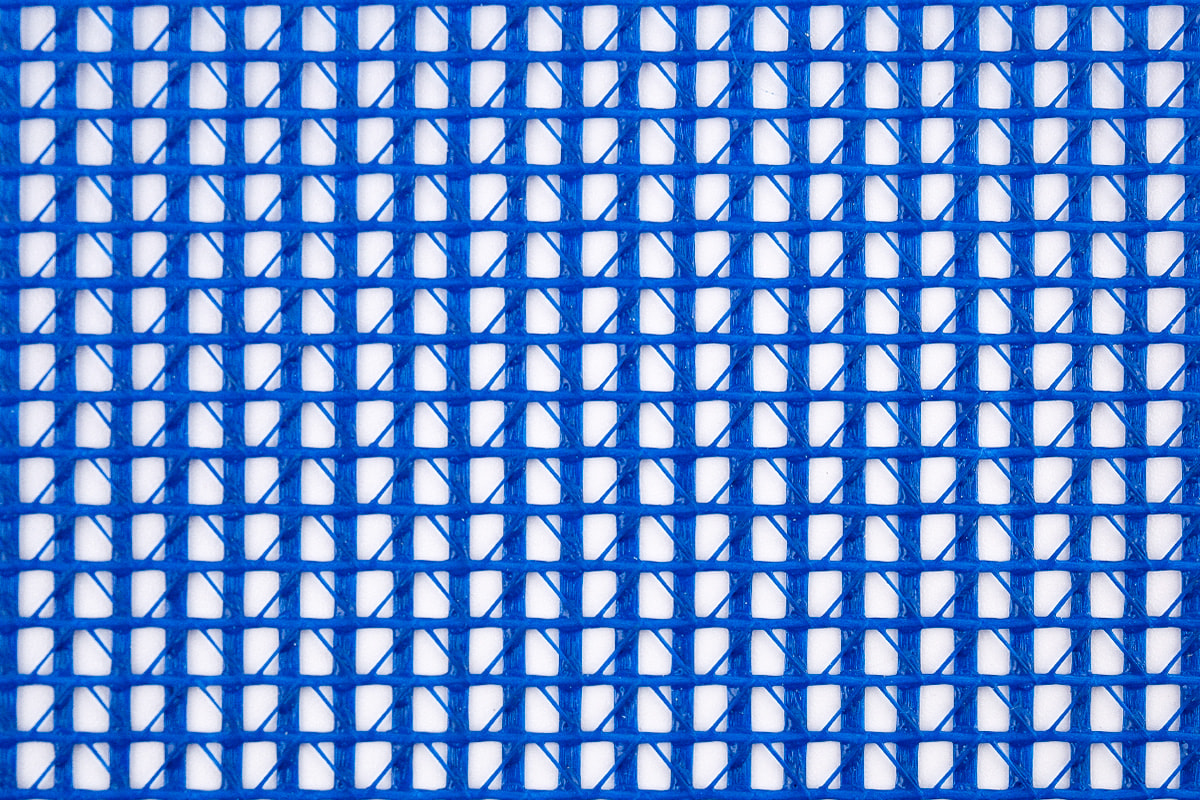

Once raw materials are selected, the next step in a Solar Screen Mesh Fabric factory is weaving. The fibers are spun and aligned into a tight mesh structure, with uniform spacing to achieve the desired sunlight control. Weave density affects both light transmission and solar heat reduction: tighter weaves block more sunlight but reduce visibility, while looser weaves preserve light flow.

Modern factories often use automated looms to maintain consistency and precision. Quality monitoring during weaving ensures even tension, proper alignment, and consistent mesh size across the entire roll.

Coating and Finishing

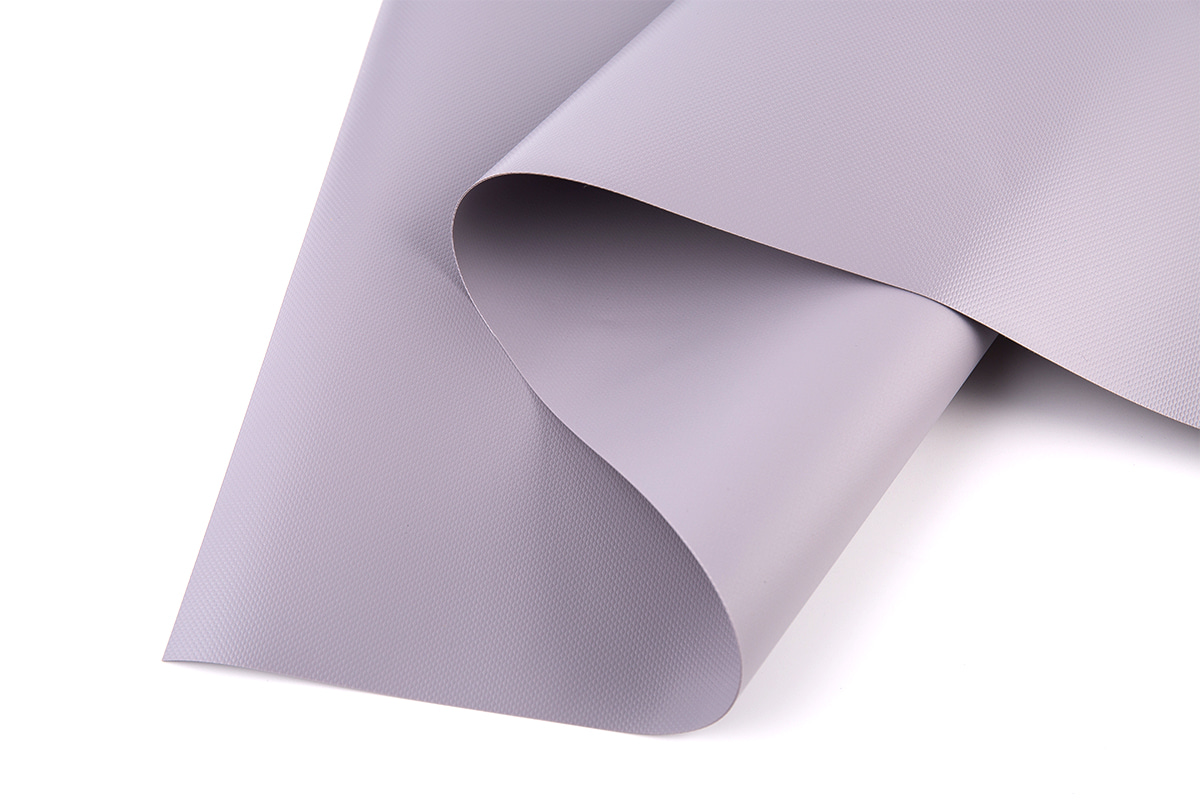

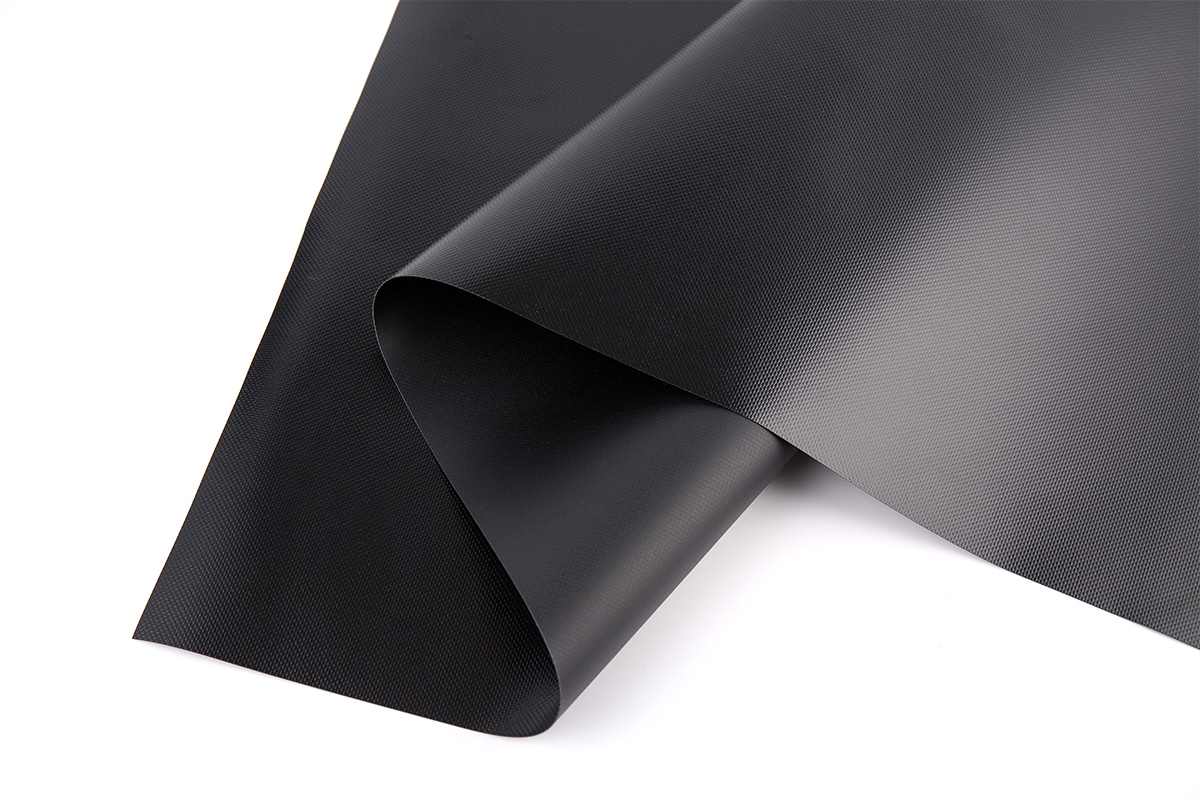

After weaving, the fabric may undergo additional coating or finishing. PVC coating, for example, improves weather resistance and extends the lifespan of the mesh. Some factories apply UV stabilizers to prevent discoloration and degradation under prolonged sun exposure. Surface treatments also enhance flexibility and reduce fraying, which is important for installation and long-term performance.

These finishing steps are carefully controlled in a Solar Screen Mesh Fabric factory to ensure uniform coverage and durability.

Quality Control and Testing

Quality assurance is a major part of the manufacturing process. Factories test Solar Screen Mesh Fabric for tensile strength, tear resistance, UV stability, and dimensional accuracy. Samples may undergo simulated weathering, abrasion tests, and colorfastness checks to ensure consistent performance.

Regular inspections during production catch defects early, reducing waste and ensuring that each roll meets the required specifications for industrial or commercial clients.

Cutting, Rolling, and Packaging

Once tested, the fabric is cut to standard widths or custom sizes as required by clients. The rolls are tightly wound and labeled with batch information for traceability. Packaging is designed to protect the fabric during transportation and storage, preventing moisture damage or deformation.

Customization and Industrial Flexibility

A Solar Screen Mesh Fabric factory often provides customized options for color, coating type, weave density, and roll width. This flexibility allows manufacturers to meet diverse client demands, from residential windows to large commercial curtain wall projects.

Manufacturing Solar Screen Mesh Fabric is a precise and multi-step process that combines careful material selection, controlled weaving, surface finishing, and rigorous quality checks. A factory environment ensures consistent strength, durability, and solar performance, making the fabric a reliable solution for sunlight control in homes and commercial buildings. Understanding the production process highlights why factory standards matter and how careful manufacturing contributes to long-term functionality.

en

en Español

Español