Safety in vehicles depends on many components, and one of the critical is the seat belt. At the heart of every seat belt system is the Car Seat Belt Webbing, a strong fabric strap designed to secure passengers and reduce injury during sudden stops or collisions.

The Role of Car Seat Belt Webbing

Car Seat Belt Webbing forms the main restraint element of seat belts. Unlike ordinary fabric, this webbing is engineered to handle high tensile loads while remaining flexible enough for comfortable use. It transfers the force of impact across the body, helping prevent passengers from striking the dashboard, windshield, or other hard surfaces.

Manufacturers of car seat belt webbing focus on both strength and consistency. Even small variations in thickness, weave, or material quality can affect performance, so precision is key.

Materials and Weaving Techniques

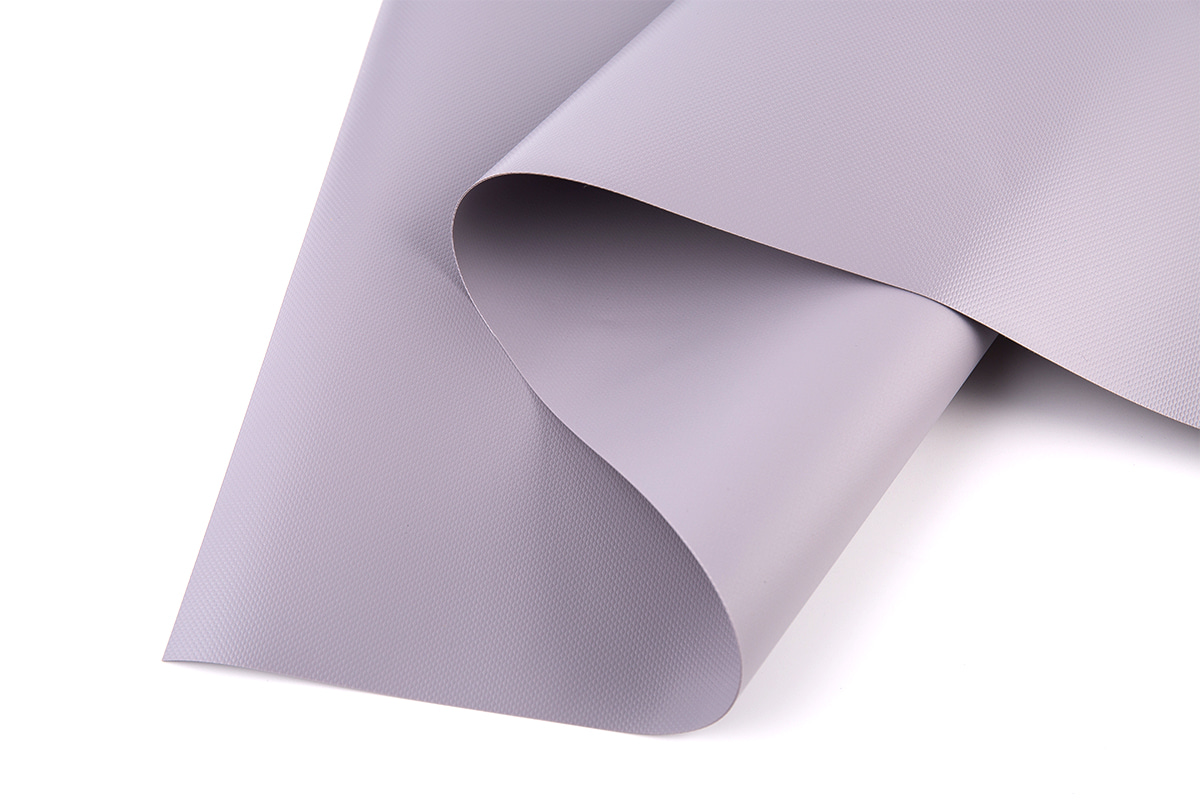

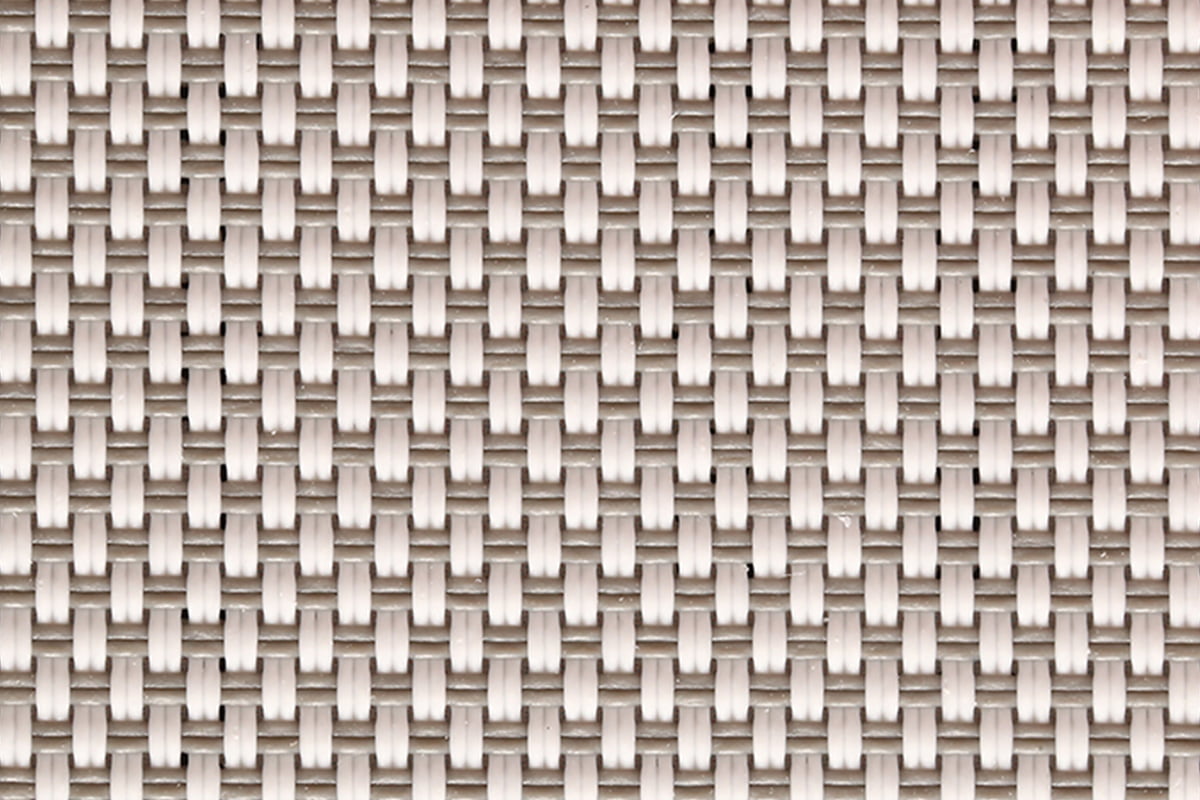

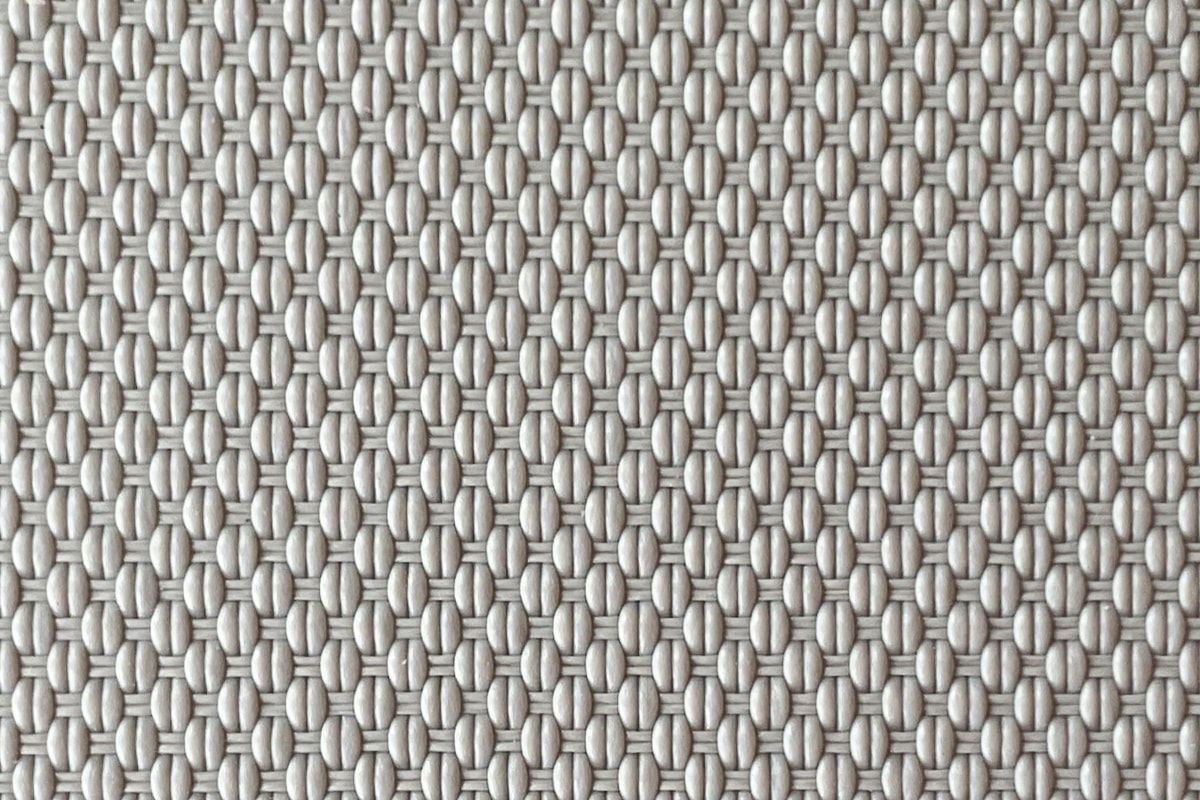

The materials used in car seat belt webbing are carefully selected for durability and resistance. Typically, polyester or high-strength nylon is used due to their tensile strength, low elongation, and resistance to abrasion. Some webbing also undergoes specialized coatings to resist UV light, moisture, or heat.

Weaving techniques also contribute to performance. A tight, uniform weave ensures the webbing stretches minimally under load while distributing force evenly. This makes the belt strong enough to handle high-speed impacts while remaining comfortable for daily use.

Production Process and Quality Control

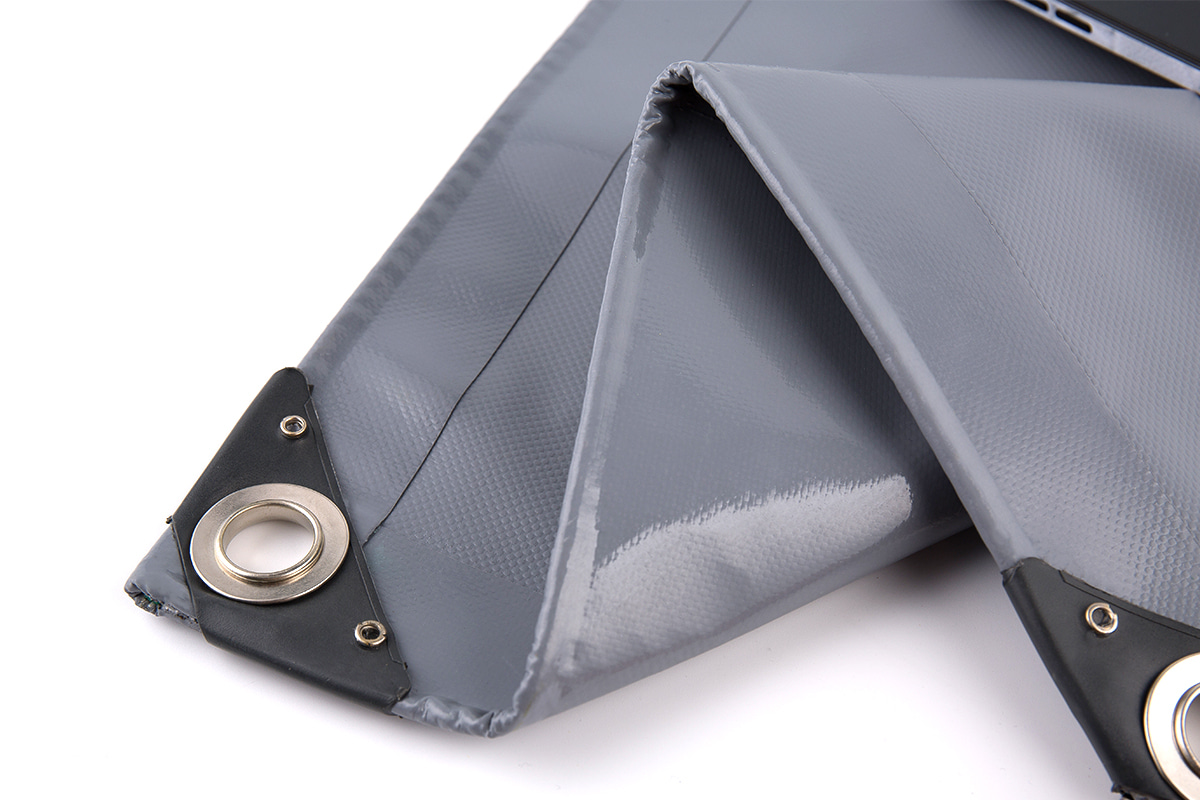

The production of Car Seat Belt Webbing involves several stages. Raw fibers are spun and dyed, then woven into wide rolls of webbing. Once woven, the webbing is inspected for defects, strength tested, and treated to improve durability or surface texture.

Quality control is rigorous. Factories may check thickness, tensile strength, elongation, and abrasion resistance. Sample webbing is often tested in simulated crash conditions to confirm it meets safety regulations. Consistent quality ensures that each seat belt performs reliably under stress.

Customization for Vehicle Models

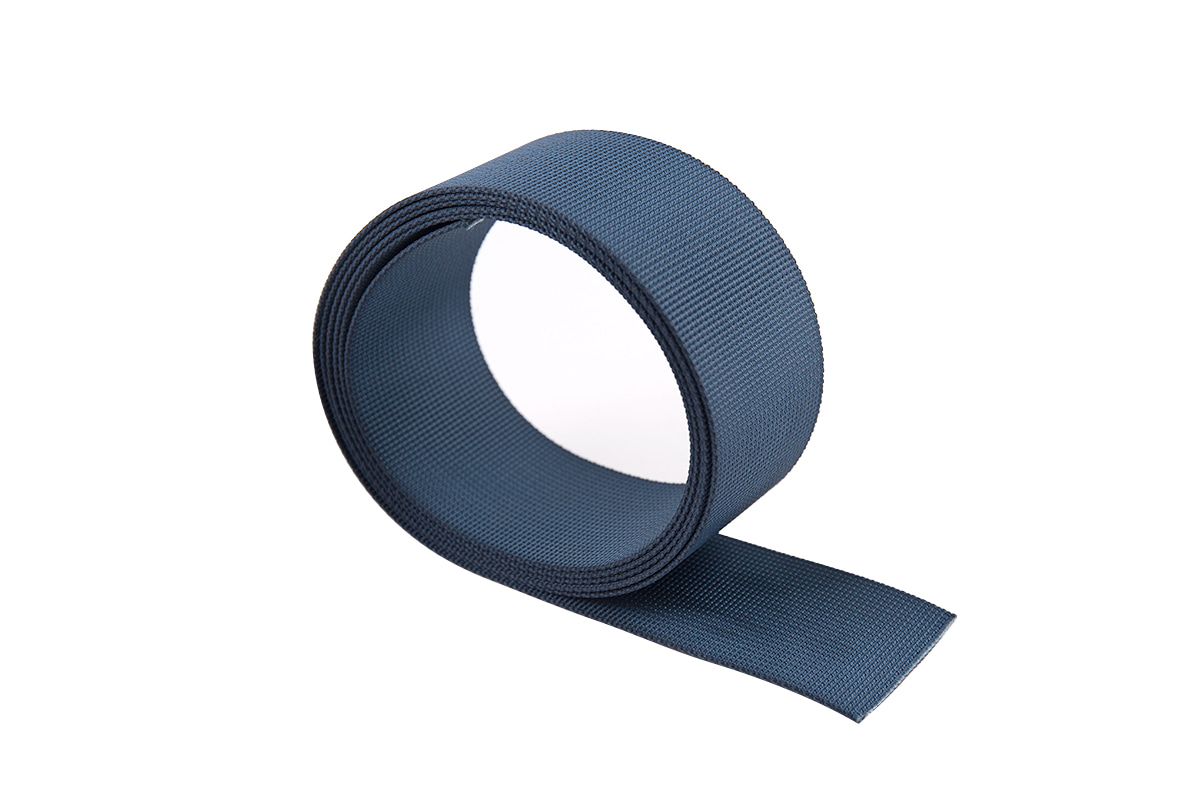

Different vehicles require different webbing lengths, widths, and colors. Car Seat Belt Webbing manufacturers often provide customization to meet the specifications of car makers, ensuring that belts integrate smoothly with retractors, buckles, and anchors.

Customization can also include patterns or branding, allowing car manufacturers to align safety components with interior design without compromising function.

Durability and Maintenance

Car Seat Belt Webbing is designed to last many years, even under frequent use. Its resistance to wear, UV exposure, and temperature fluctuations is critical for long-term performance. Vehicle owners should regularly inspect webbing for fraying, cuts, or damage, as compromised webbing may not provide adequate protection.

Simple care, such as gentle cleaning with mild soap and water, can maintain webbing flexibility and appearance without reducing safety.

The Importance of Reliable Webbing

Reliable car seat belt webbing is essential for overall passenger safety. In a crash, the webbing must hold strong while stretching just enough to absorb force. Properly manufactured and maintained webbing ensures the seat belt performs its intended function, protecting occupants and reducing the risk of injury.

Car Seat Belt Webbing is more than a strip of fabric—it is a critical safety component in every vehicle. Through careful material selection, precise weaving, and rigorous quality control, manufacturers produce webbing that is strong, durable, and reliable. Understanding the production and function of car seat belt webbing highlights its importance for daily driving safety, making it clear why consistent quality is essential for every vehicle.

en

en Español

Español