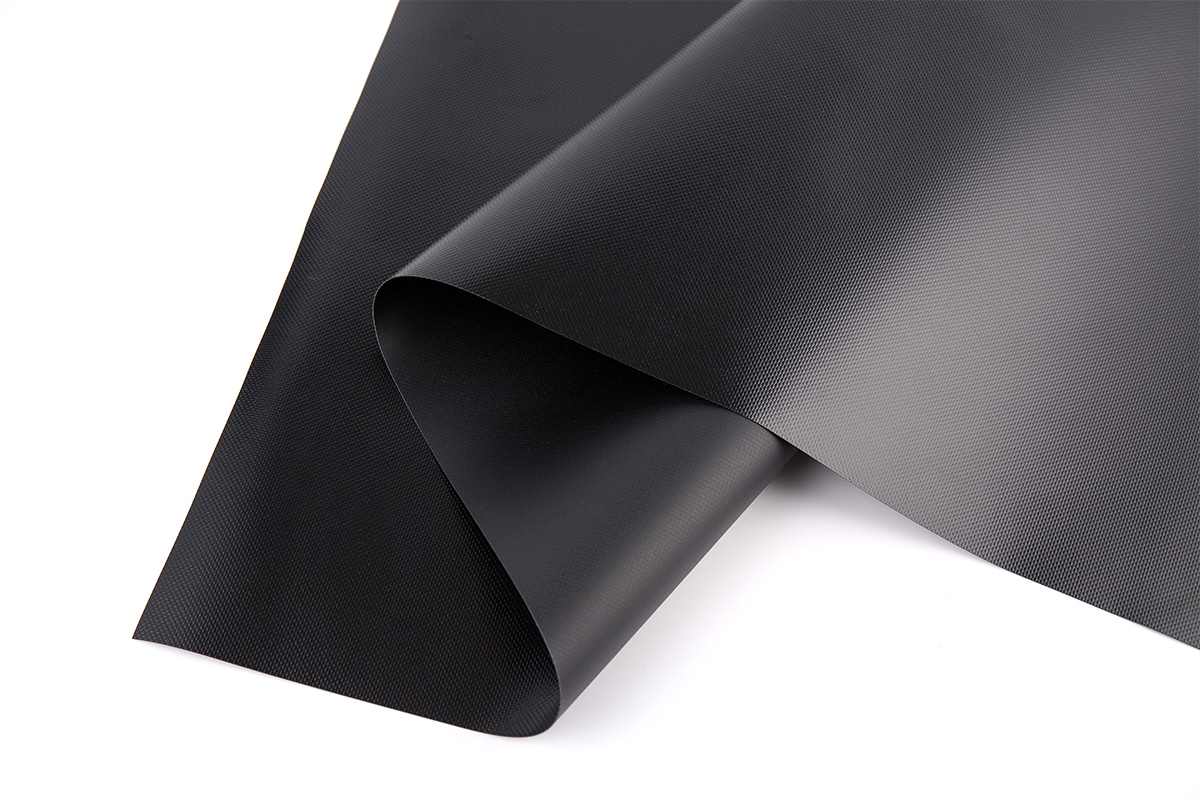

PVC mesh fabric is widely used in outdoor coverings, banners, tents, and industrial applications. The production of this versatile material requires careful handling of raw materials, weaving processes, and coating techniques. A PVC Mesh Fabric Factory ensures that the final product meets quality, durability, and functional requirements for various end-use applications.

Role of a PVC Mesh Fabric Factory

A PVC Mesh Fabric Factory is responsible for converting raw threads and PVC coatings into finished mesh products. The factory manages each stage of production, from selecting polyester or other synthetic yarns to coating, heat treatment, and finishing. Each step influences strength, flexibility, and resistance to environmental conditions such as UV exposure, moisture, and wear.

By maintaining consistency in production, a PVC Mesh Fabric Factory ensures that each roll of fabric performs as expected in industrial or commercial applications. This consistency is important for manufacturers and distributors who rely on predictable material performance.

Material Selection and Preparation

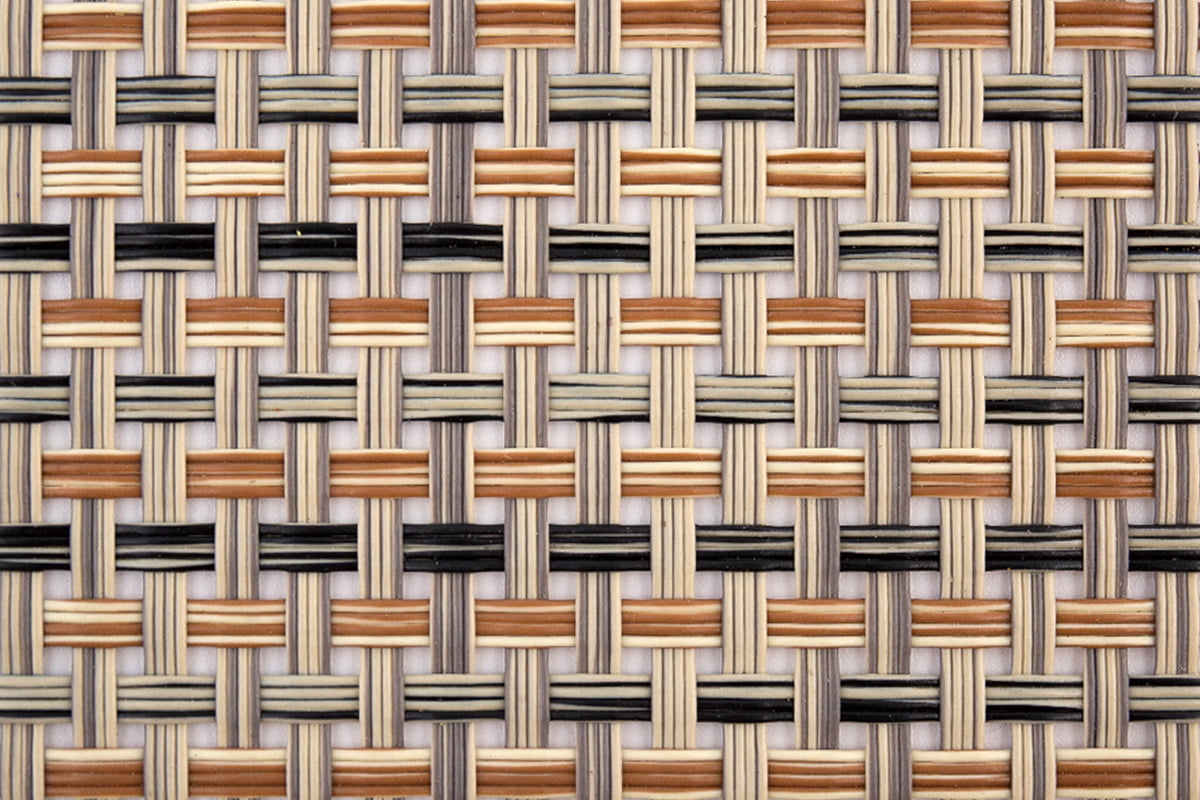

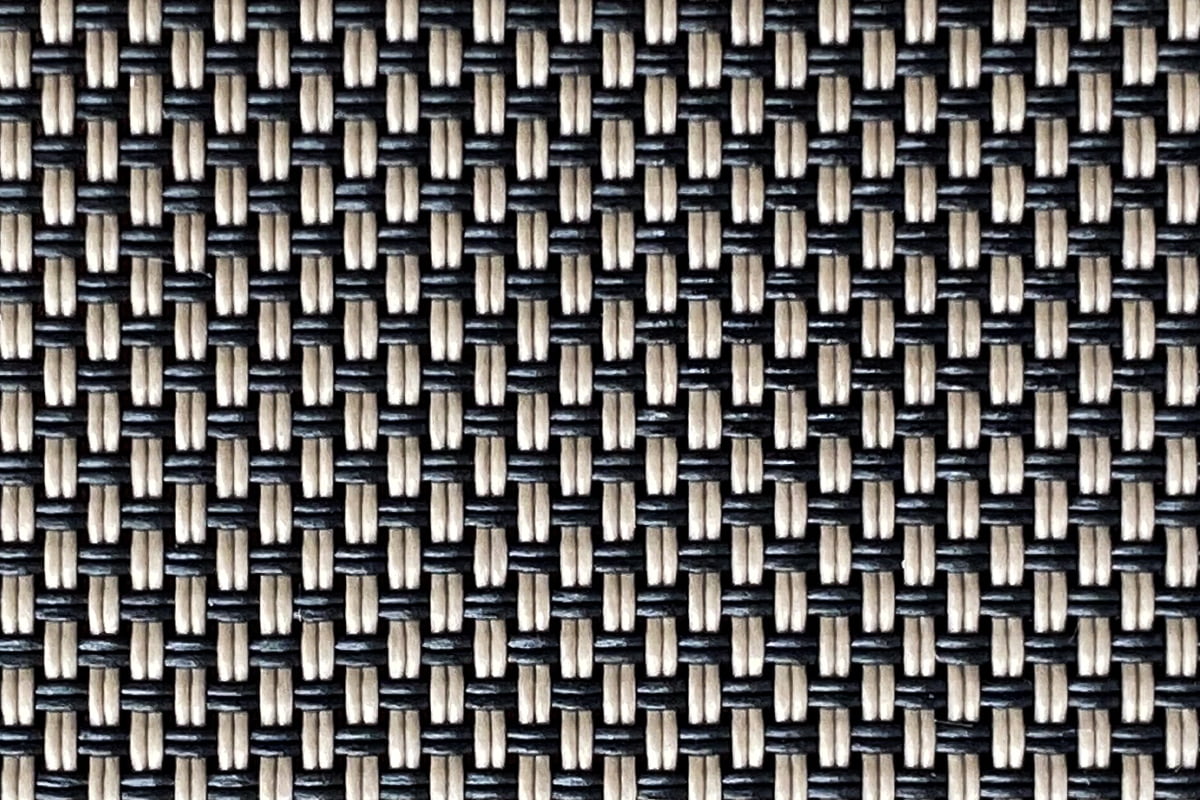

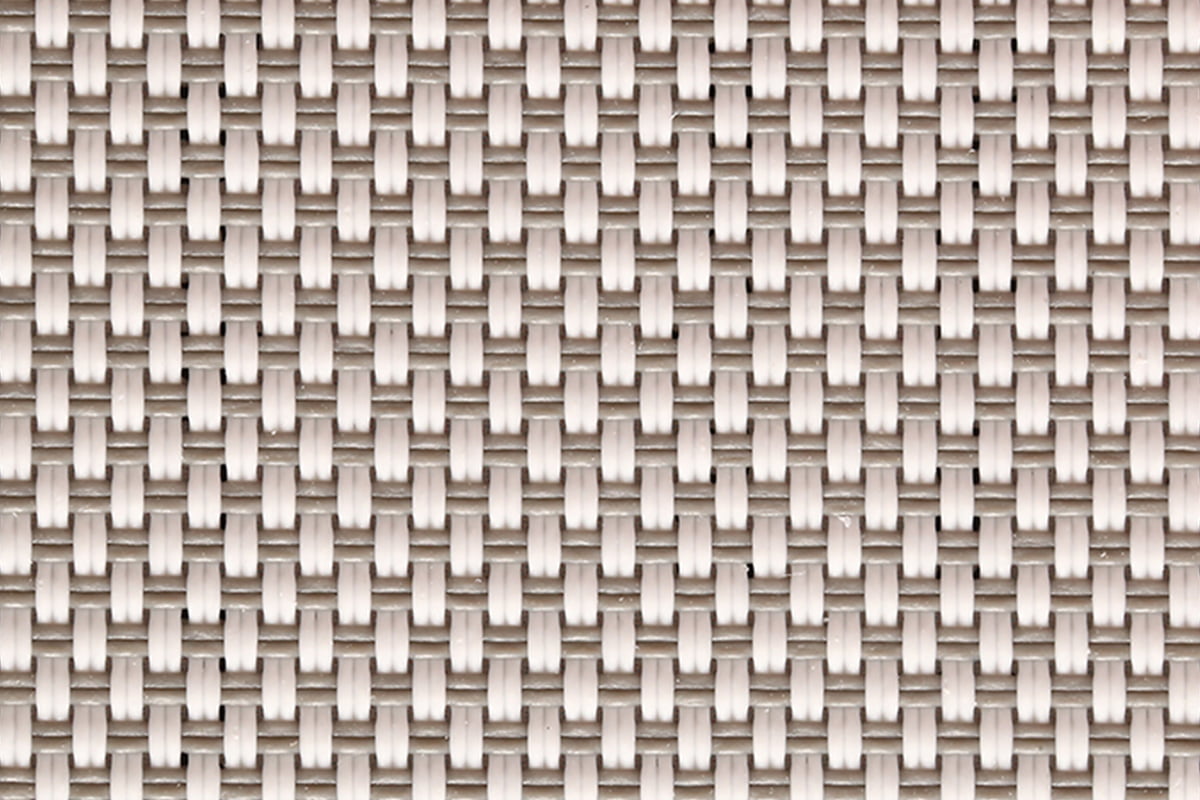

Material selection is one of the important steps in a PVC Mesh Fabric Factory. Polyester or nylon threads are commonly chosen for their tensile strength and flexibility. The mesh pattern is designed to balance airflow, weight, and durability.

PVC coating is applied to provide additional resistance to abrasion, water, and sunlight. The factory often controls coating thickness and uniformity to achieve the desired balance between protection and flexibility. Quality raw materials and precise preparation help produce durable and reliable mesh fabric.

Manufacturing Process

The production process typically begins with weaving or knitting the selected yarns into a mesh pattern. After weaving, PVC coating is applied either through calendaring, dipping, or coating machines. The coated fabric is then cured under controlled temperature conditions to ensure proper adhesion and durability.

Once cured, the fabric is inspected for defects, including uneven coating, weak areas, or irregular mesh patterns. The final product is rolled, labeled, and packaged for shipment. By controlling each stage, a PVC Mesh Fabric Factory ensures that the fabric meets both performance and safety requirements.

Applications of PVC Mesh Fabric

PVC mesh fabric is versatile and used across multiple industries. It is commonly applied in outdoor banners, tarpaulins, tents, construction safety nets, and even furniture covers. Its durability, combined with light weight and flexibility, makes it suitable for both temporary and permanent installations.

Manufacturers and suppliers rely on PVC Mesh Fabric Factories to deliver products that can withstand repeated use, exposure to weather, and mechanical stress. This reliability is particularly important for projects where safety and longevity are critical.

Quality Control and Industry Standards

Quality control is a continuous process in a PVC Mesh Fabric Factory. Each batch of fabric is tested for tensile strength, coating adhesion, flame resistance (if applicable), and dimensional consistency. These checks help prevent defects and maintain customer confidence.

Factories may also offer customization options such as color, mesh size, or coating type to meet specific client requirements. Clear labeling and documentation ensure buyers understand the product specifications and appropriate use cases.

A PVC Mesh Fabric Factory plays a critical role in producing durable, flexible, and functional mesh fabrics for a wide range of industries. From raw material selection to weaving, coating, and inspection, each step contributes to the overall quality and reliability of the final product. For manufacturers, distributors, and end-users, understanding the operations of a PVC Mesh Fabric Factory helps ensure that their projects receive material that meets performance and durability expectations.

en

en Español

Español