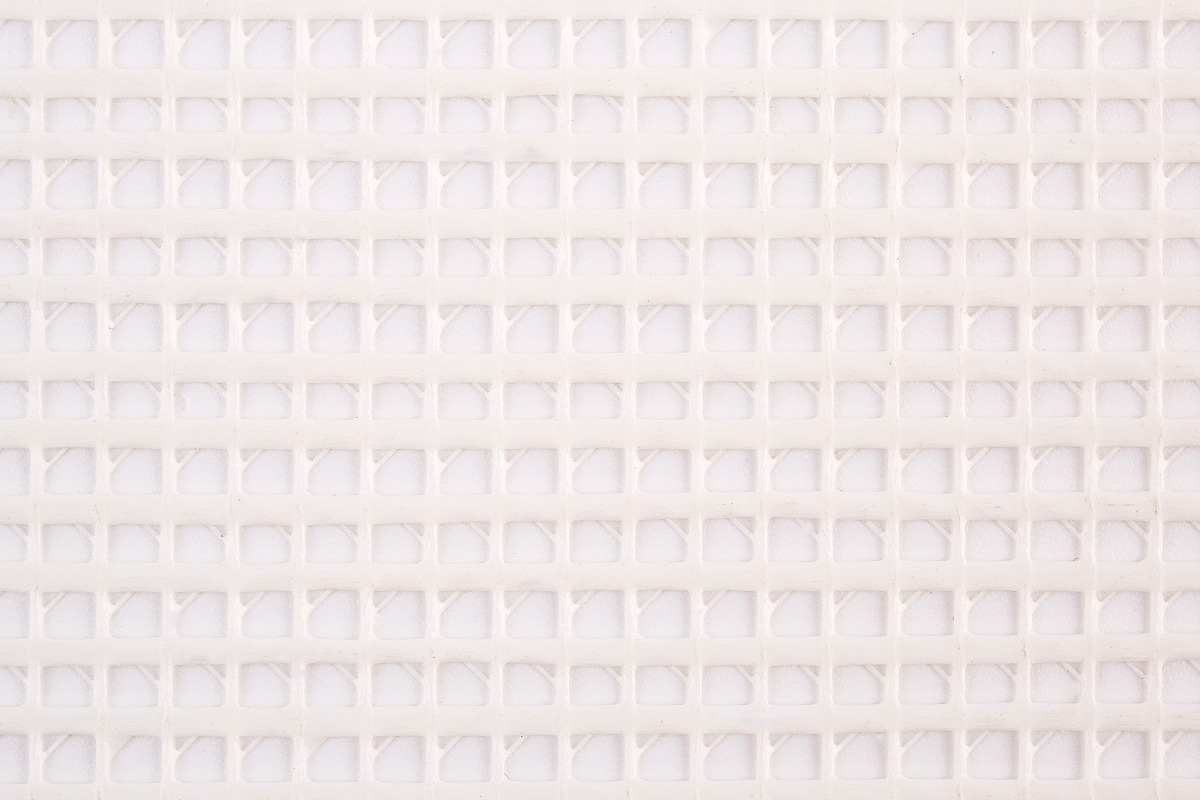

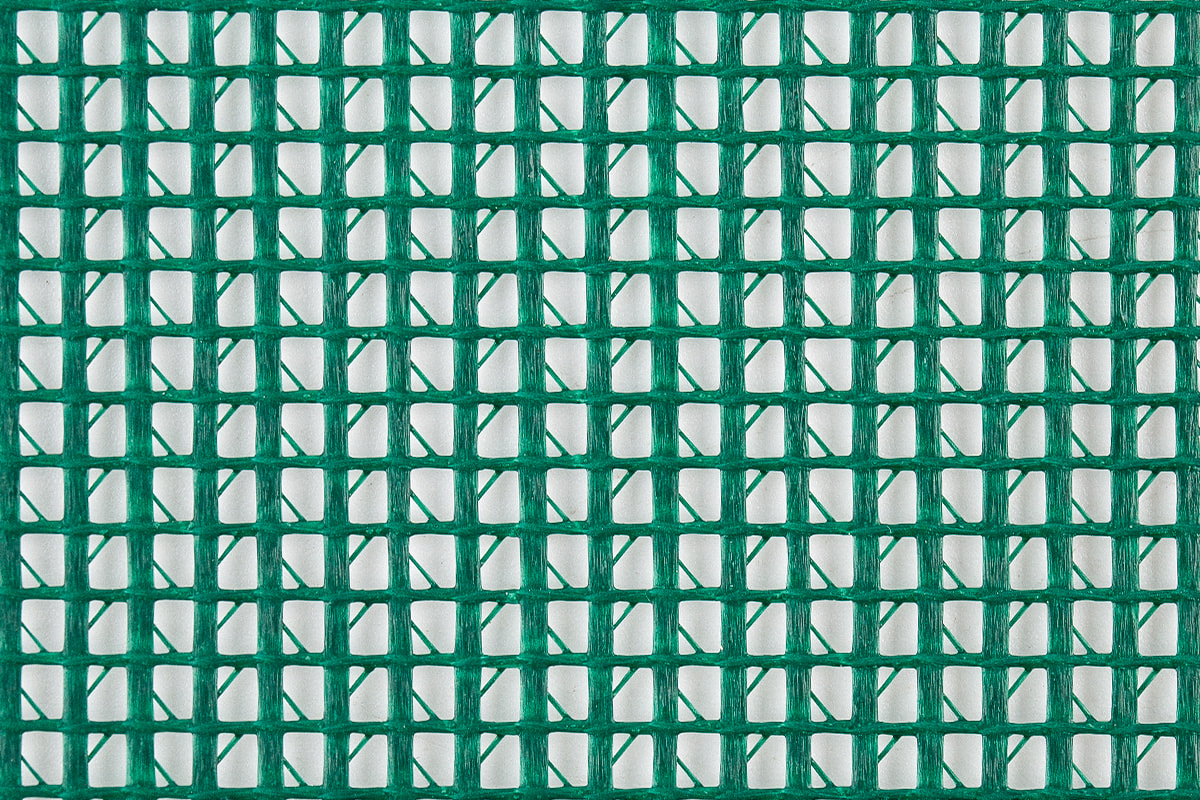

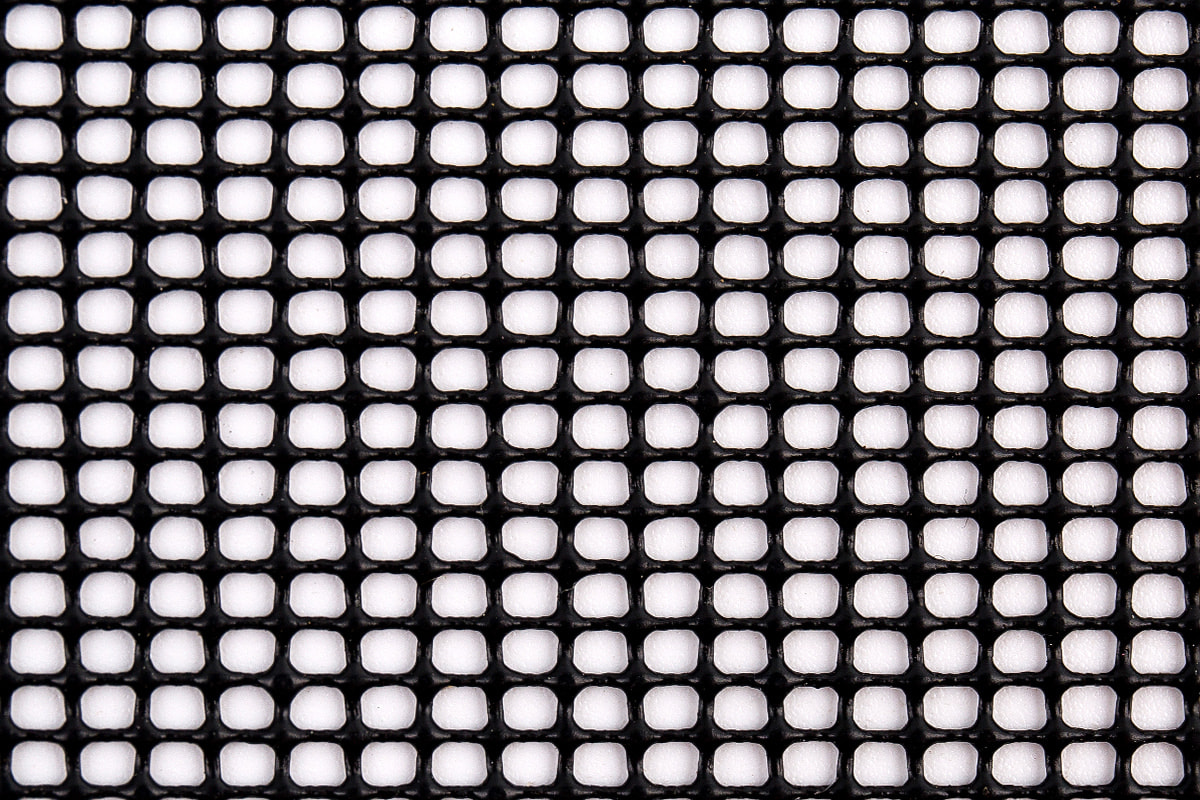

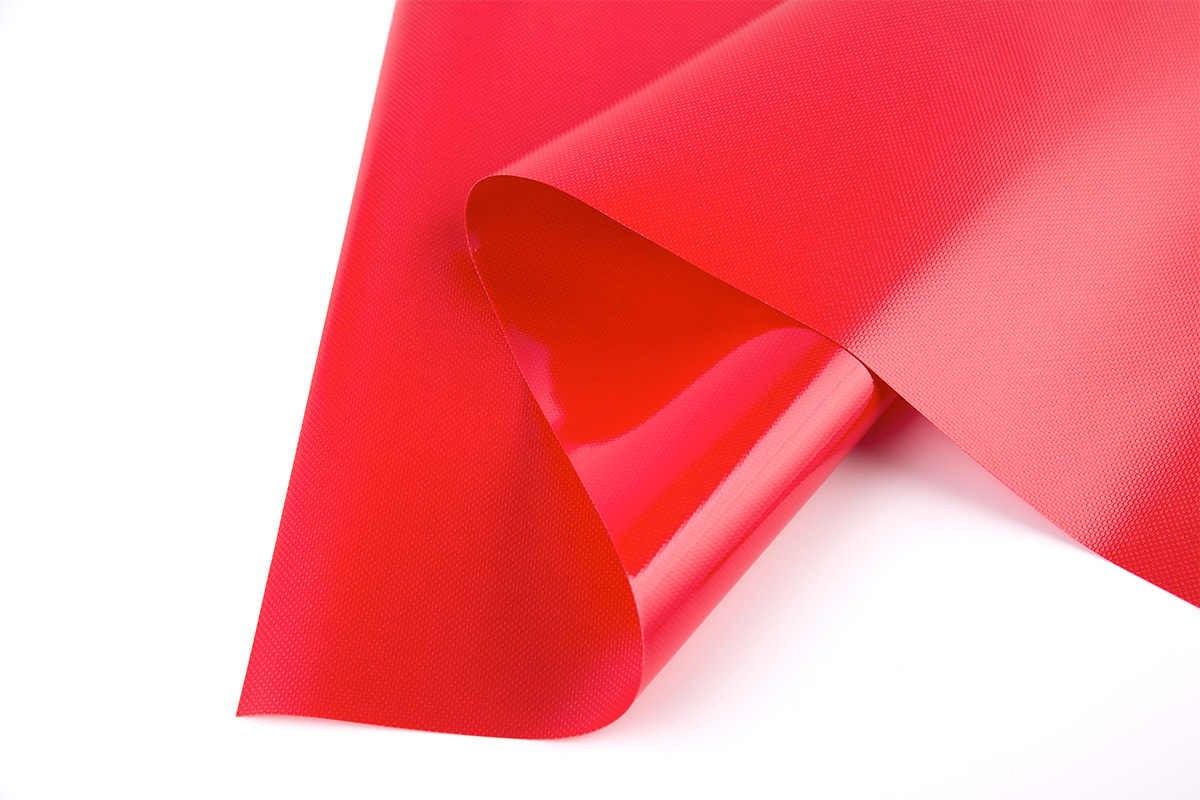

PVC mesh fabric is widely used in applications ranging from industrial coverings to outdoor furniture and sports equipment. Ensuring the durability of this material is essential for both manufacturers and end-users. PVC mesh fabric factories employ a series of tests to evaluate strength, flexibility, and resistance to environmental factors.

Tensile Strength Testing

One of the primary measures of durability is tensile strength. PVC mesh fabric factories perform tensile tests to determine how much force the material can withstand before tearing. Samples are stretched using specialized equipment that records the breaking point and elongation. This test helps factories ensure that the mesh can handle expected loads in its intended applications. By regularly testing tensile strength, factories can maintain consistent production standards and adjust material composition if needed.

Abrasion and Wear Resistance

Abrasion resistance is another key factor in durability. PVC mesh is often exposed to friction, whether in outdoor settings or during handling and transportation. Factories use abrasion testing machines to simulate repeated wear on fabric samples. These machines apply controlled rubbing or scraping to the mesh, assessing how quickly the surface deteriorates. Results guide manufacturers in selecting suitable coatings or reinforcement techniques that extend the fabric's service life.

UV and Weather Resistance

Many PVC mesh products are used outdoors, making UV and weather resistance essential. PVC mesh fabric factories conduct accelerated weathering tests that expose samples to intense sunlight, moisture, and temperature fluctuations. These tests help evaluate color retention, strength maintenance, and overall material integrity under environmental stress. By assessing UV and weather resistance, factories can offer products suitable for long-term outdoor use, reducing the risk of premature fading, cracking, or brittleness.

Chemical and Stain Resistance

Durability also includes the fabric's ability to resist chemicals and stains. PVC mesh may come into contact with oils, cleaning agents, or other substances during use. Factories test resistance by applying various chemicals to fabric samples and observing changes in appearance or structure. Stain resistance tests ensure that the material maintains visual quality while remaining easy to clean, which is particularly important for commercial and consumer applications.

Quality Control and Batch Testing

Beyond individual tests, PVC mesh fabric factories implement batch testing as part of quality control. Random samples from production batches are tested for consistency in strength, flexibility, and resistance properties. This process helps identify any variations in raw materials or manufacturing conditions that could affect durability. Continuous quality monitoring ensures that the final product meets performance expectations and reduces the likelihood of defects reaching customers.

PVC mesh fabric factories use a combination of tensile, abrasion, UV, weather, and chemical resistance tests to evaluate and ensure durability. These assessments help maintain consistent quality, adapt production processes, and provide products that withstand environmental and operational challenges. By understanding the testing procedures employed by these factories, buyers can make informed decisions when selecting PVC mesh fabrics for various applications. Durable materials not only improve product performance but also enhance long-term satisfaction for both commercial and personal use.

en

en Español

Español