Vinyl woven mesh fabrics are widely used in outdoor furniture, shading solutions, and industrial applications due to their durability, breathability, and resistance to weather conditions. Businesses and designers often require custom specifications to meet unique project needs. This raises the question: can vinyl woven mesh fabric manufacturers offer custom solutions for bulk orders? The answer is yes, and understanding the customization process can help buyers get fabrics that meet their exact requirements.

Customization Options

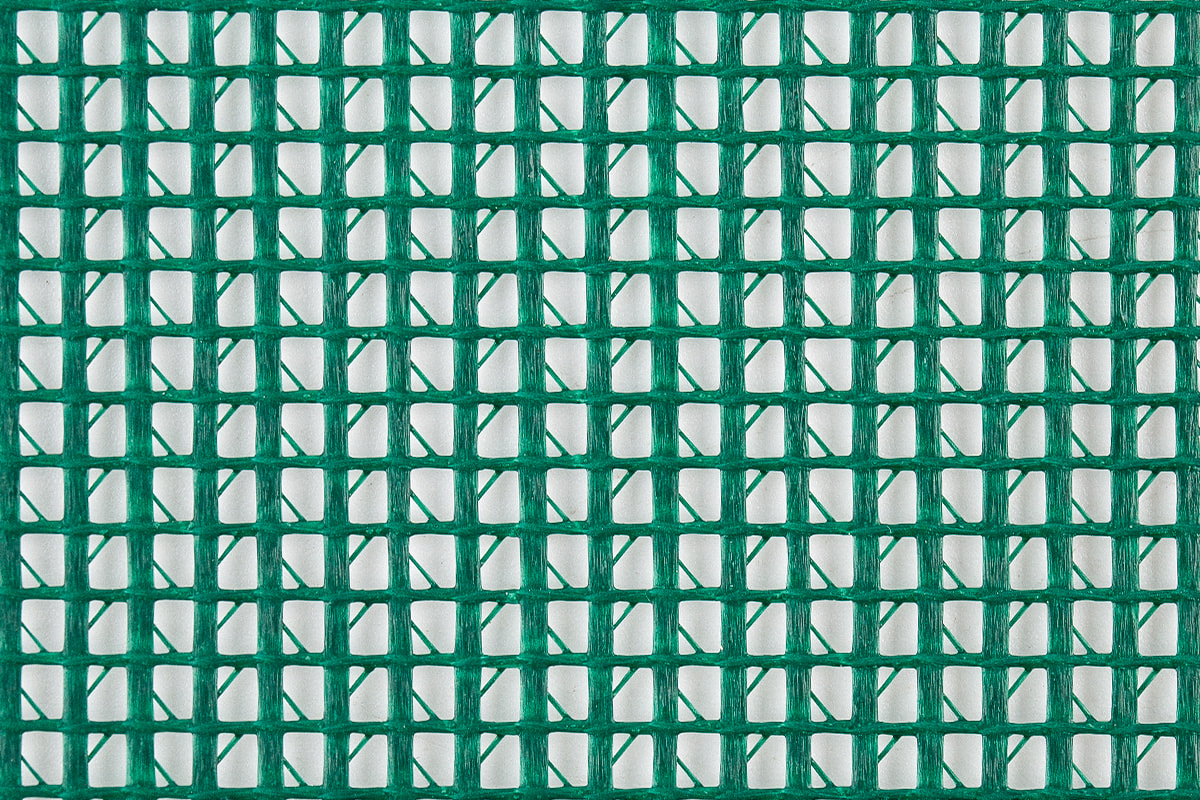

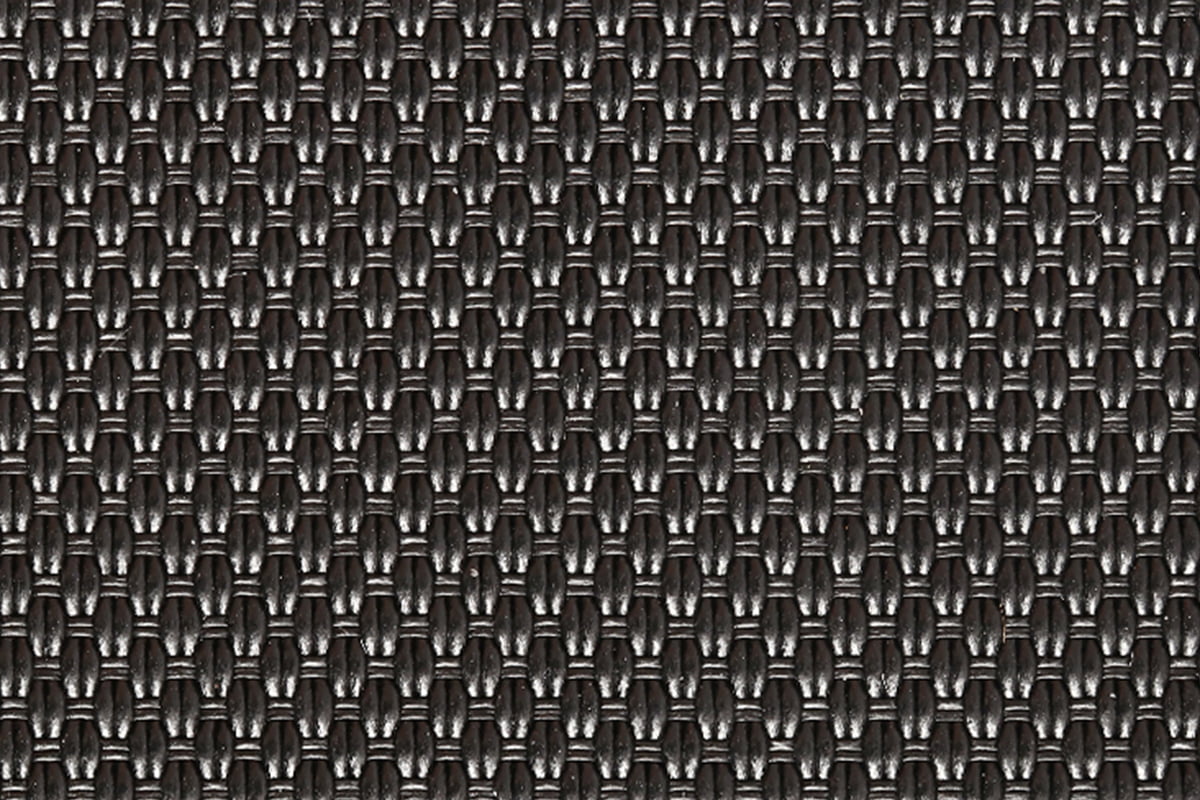

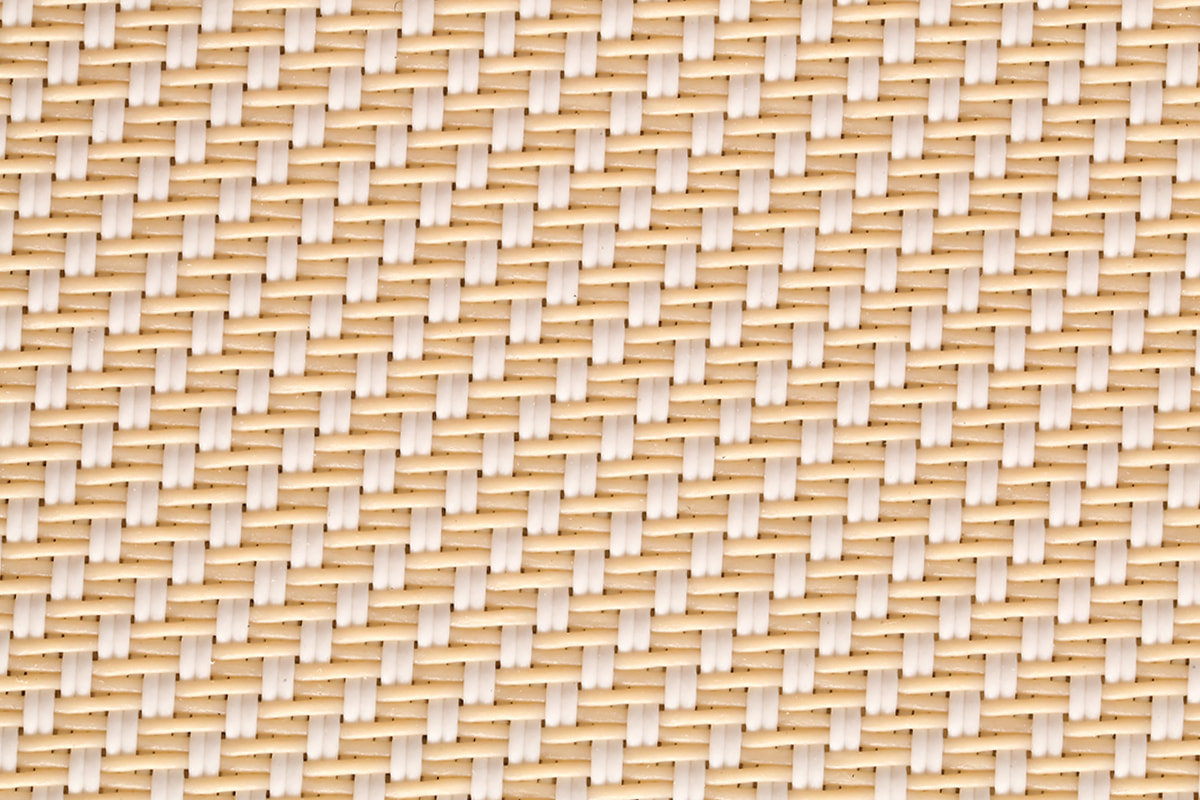

Vinyl woven mesh fabric manufacturers typically provide a range of customization options. This includes selecting the fabric's width, length, and color, as well as specifying mesh density and yarn thickness. These factors influence the fabric's strength, flexibility, and appearance. For example, a higher mesh density may be suitable for applications requiring privacy or sun protection, while lower density can offer more airflow. By communicating their requirements clearly, buyers can ensure that the custom fabrics align with the intended use.

Material Selection

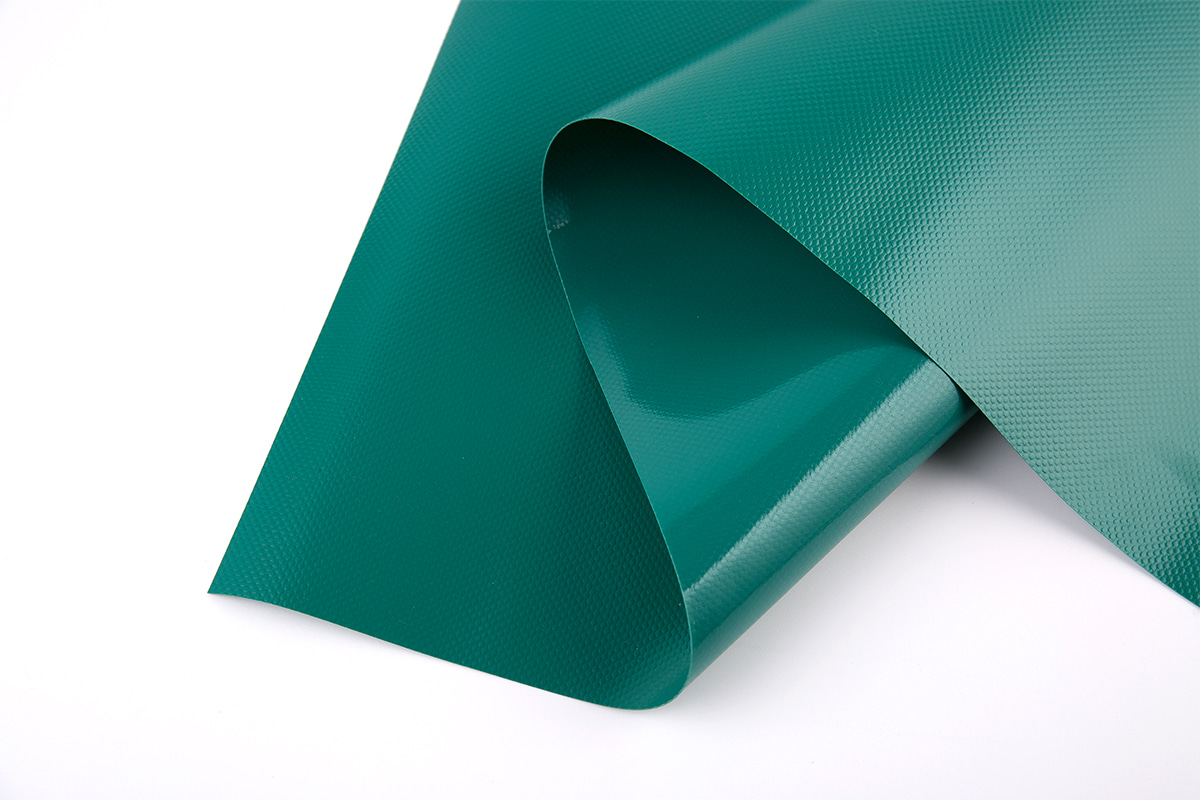

The core material in vinyl woven mesh fabrics is typically PVC-coated polyester or similar synthetic fibers. Manufacturers can adjust the composition and coating thickness to enhance durability, UV resistance, or fire retardancy. Some clients request eco-friendly materials or specialized coatings for industrial applications. Vinyl woven mesh fabric manufacturers are able to accommodate these requests, provided that the specifications are feasible within their production capabilities.

Color and Printing Options

Customization often extends to colors and patterns. Manufacturers can offer a wide palette of colors or even custom shades to match brand identity or project design. Some fabrics may also feature printed designs or logos. Vinyl woven mesh fabric manufacturers use specialized printing techniques that do not compromise the fabric's strength or weather resistance. This allows for both aesthetic appeal and functional performance in outdoor or commercial settings.

Production Considerations

Custom orders generally require more planning than standard products. Vinyl woven mesh fabric manufacturers will often request detailed specifications, including fabric dimensions, mesh count, color codes, and any additional features such as UV or fire resistance. Production timelines may be longer for custom fabrics, especially for large or complex orders. Bulk buyers are encouraged to coordinate closely with the manufacturer to ensure that timelines, quality standards, and budget constraints are all met.

Quality Assurance

Even with customization, maintaining quality standards is critical. Reputable vinyl woven mesh fabric manufacturers conduct inspections at multiple stages of production, checking for consistency in weave, color, coating, and overall durability. Some manufacturers also provide samples for client approval before starting large production runs. This helps ensure that the custom fabrics meet both aesthetic and functional requirements.

Vinyl woven mesh fabric manufacturers can offer a high degree of customization to meet the specific needs of clients. From adjusting mesh density and material composition to selecting colors, coatings, and patterns, manufacturers are capable of producing fabrics tailored to different applications. Close communication, detailed specifications, and collaboration with the manufacturer are key to achieving the desired outcome. By understanding the available options and planning effectively, buyers can obtain custom vinyl woven mesh fabrics that combine functionality, durability, and visual appeal for a wide range of projects.

en

en Español

Español