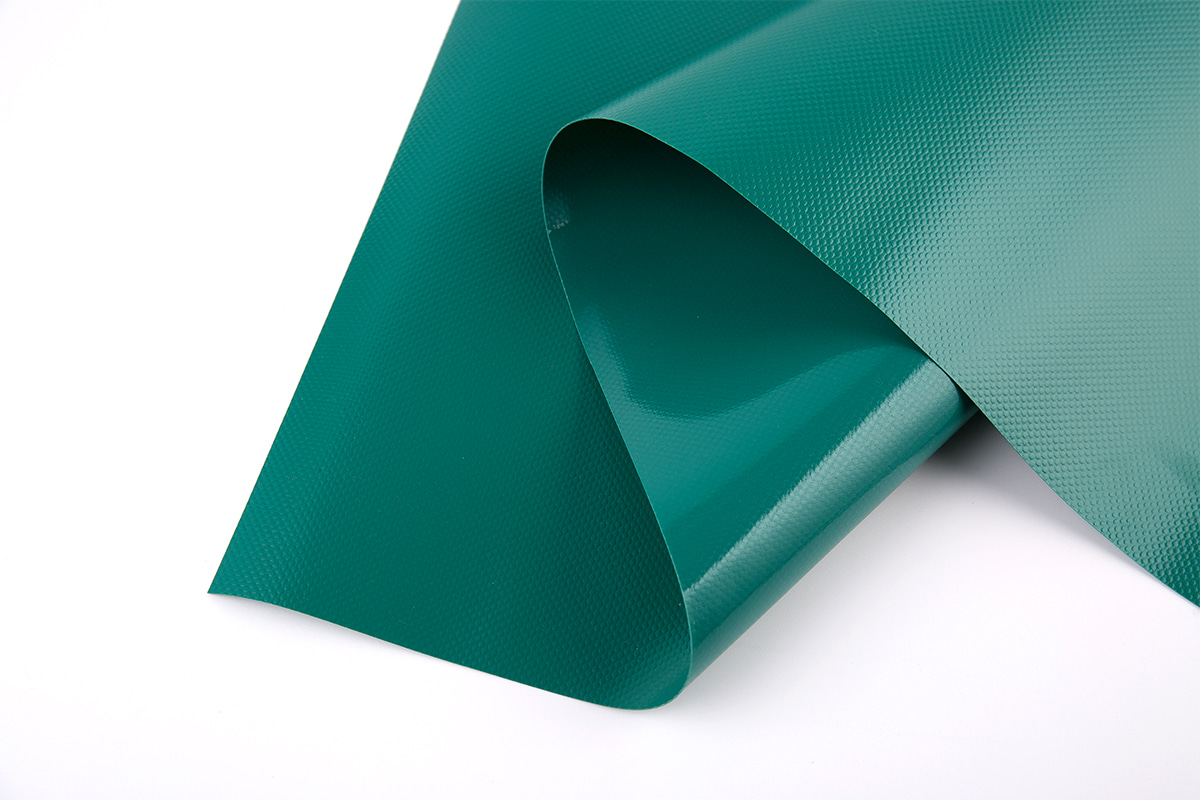

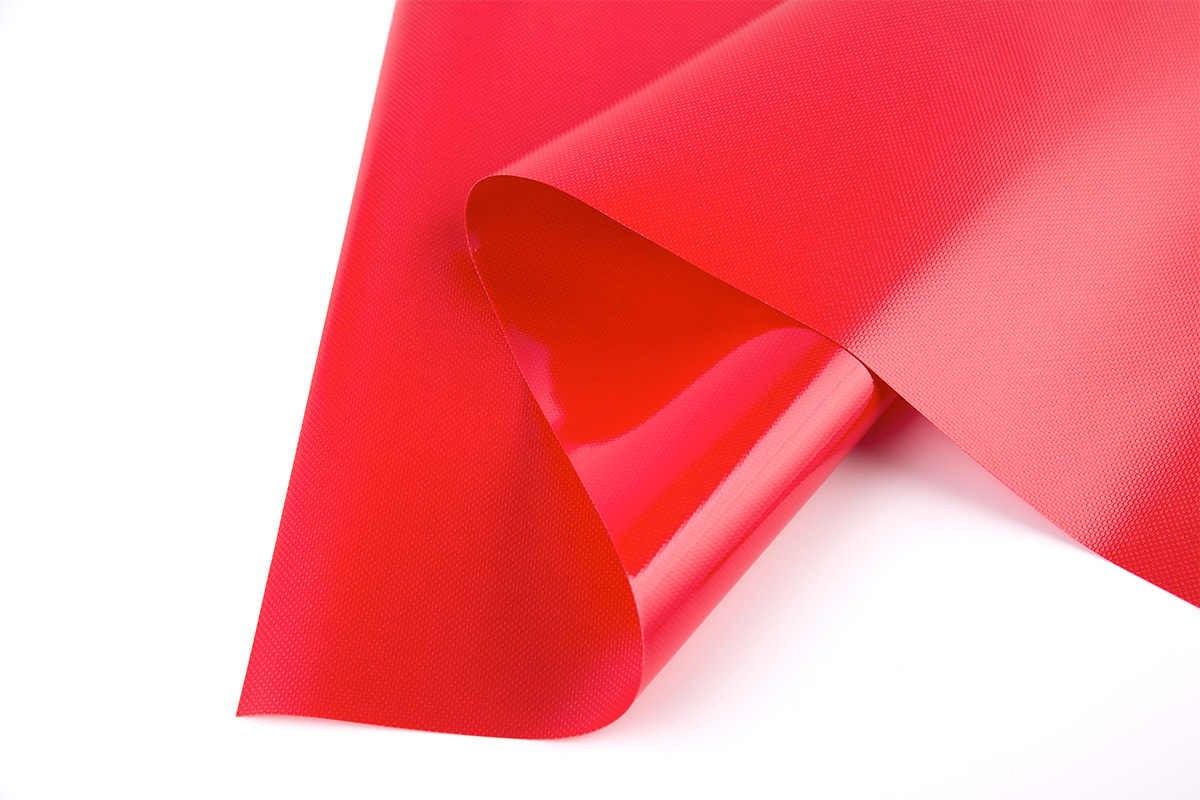

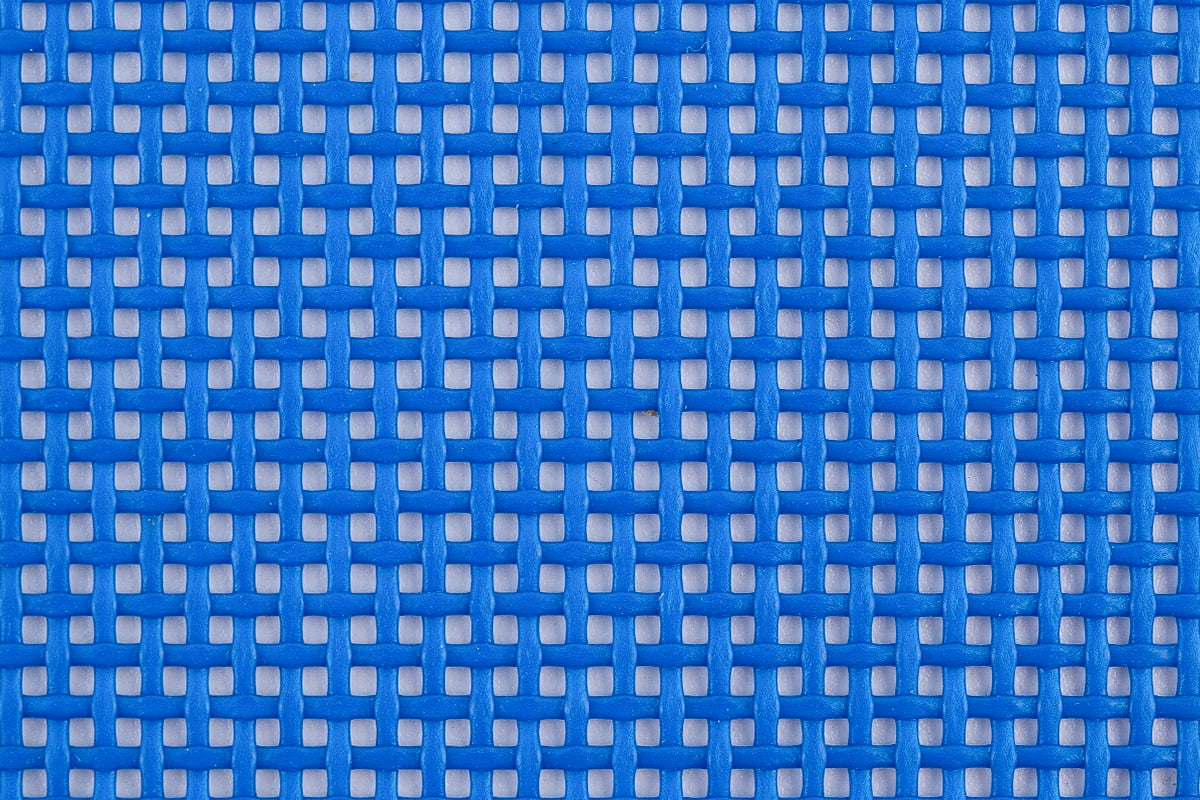

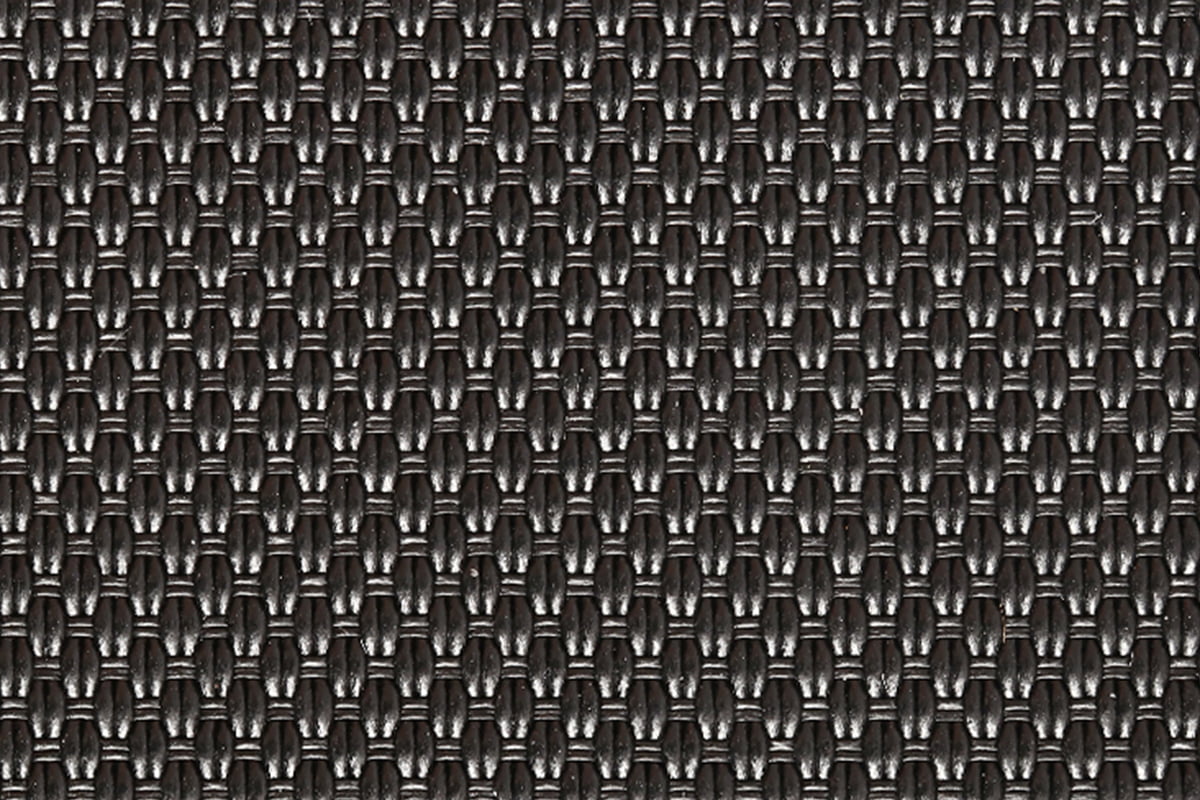

PVC Coated Polyester Yarn is a versatile material widely used in industries such as outdoor fabric manufacturing, awnings, tarpaulins, and industrial textiles. It combines the durability of polyester with the protective and flexible qualities of polyvinyl chloride (PVC), making it suitable for applications where strength, resistance to moisture, and longevity are important. Understanding how PVC Coated Polyester Yarn is manufactured offers insight into why it performs well in demanding conditions.

The manufacturing process of PVC Coated Polyester Yarn begins with the production of the base polyester yarn. Polyester fibers are synthesized from petrochemical sources, typically through a polymerization process that converts ethylene glycol and terephthalic acid into polyethylene terephthalate (PET). Once the polymer is formed, it is melted and extruded into filaments. These filaments are then cooled, stretched to increase strength, and wound onto spools as yarn.

After the base polyester yarn is produced, the next step is to prepare it for the coating process. The yarn is cleaned to remove any residual oils or particles that might affect the adhesion of the PVC layer. This is done through a washing and drying process that ensures the surface of the yarn is clean and smooth.

The core step in creating PVC Coated Polyester Yarn is the coating itself. In this stage, the polyester yarn is passed through a bath or extrusion system containing melted or liquefied PVC. There are different methods used for this step, including dip coating and extrusion coating. In dip coating, the yarn is submerged in a PVC solution and then heated to allow the PVC to bond to the fiber. In extrusion coating, melted PVC is directly applied to the yarn under controlled pressure and temperature conditions.

Once the yarn has been coated with PVC, it goes through a curing process. The coated yarn is passed through a heated chamber or oven that helps solidify the PVC layer and ensure it adheres evenly to the polyester core. Proper temperature control is critical during this stage to prevent damage to the yarn or uneven coating.

After curing, the PVC Coated Polyester Yarn is inspected for uniformity, thickness, and strength. Quality control checks are conducted to verify that the coating adheres properly and that the yarn meets required specifications for its intended use. Depending on the application, the yarn may be treated further with UV stabilizers, flame retardants, or color pigments to enhance its functional characteristics.

The manufacturing process of PVC Coated Polyester Yarn involves multiple stages: producing the base polyester yarn, cleaning it, coating it with PVC, curing the coating, conducting quality checks, and preparing the finished product for shipment. Each step plays a crucial role in ensuring that the yarn performs effectively in a range of industrial and commercial applications. The combination of polyester strength and PVC resilience makes this material a practical choice for many textile and fabric-related industries.

en

en Español

Español