Car seat belt webbing plays a crucial role in vehicle safety by restraining passengers during sudden stops or collisions. The quality and reliability of this webbing depend heavily on the materials used in its production. Car seat belt webbing manufacturers carefully select materials that provide strength, durability, and comfort to ensure that the final product meets stringent safety requirements.

One of the primary materials used in car seat belt webbing is polyester. Polyester fibers are widely favored due to their great tensile strength and resistance to abrasion. These qualities help the seat belt webbing withstand high-impact forces and prevent premature wear, which is vital for maintaining safety over time. Additionally, polyester maintains its shape and color well, even after exposure to sunlight and various weather conditions. This durability makes polyester a common choice among car seat belt webbing manufacturers.

Nylon is another material often used by car seat belt webbing manufacturers. Nylon webbing is known for its elasticity and resilience, which allows it to absorb some of the shock during a collision. This stretchiness can contribute to reducing the risk of injury by distributing the force more evenly across the passenger’s body. However, nylon can absorb moisture, which may affect its performance in certain environments. For this reason, manufacturers sometimes blend nylon with other fibers or apply protective coatings.

In some cases, manufacturers use a combination of polyester and nylon to balance strength and flexibility. By blending these materials, car seat belt webbing can achieve an effective mix of durability and shock absorption. This approach helps meet the diverse requirements of different vehicle models and safety standards.

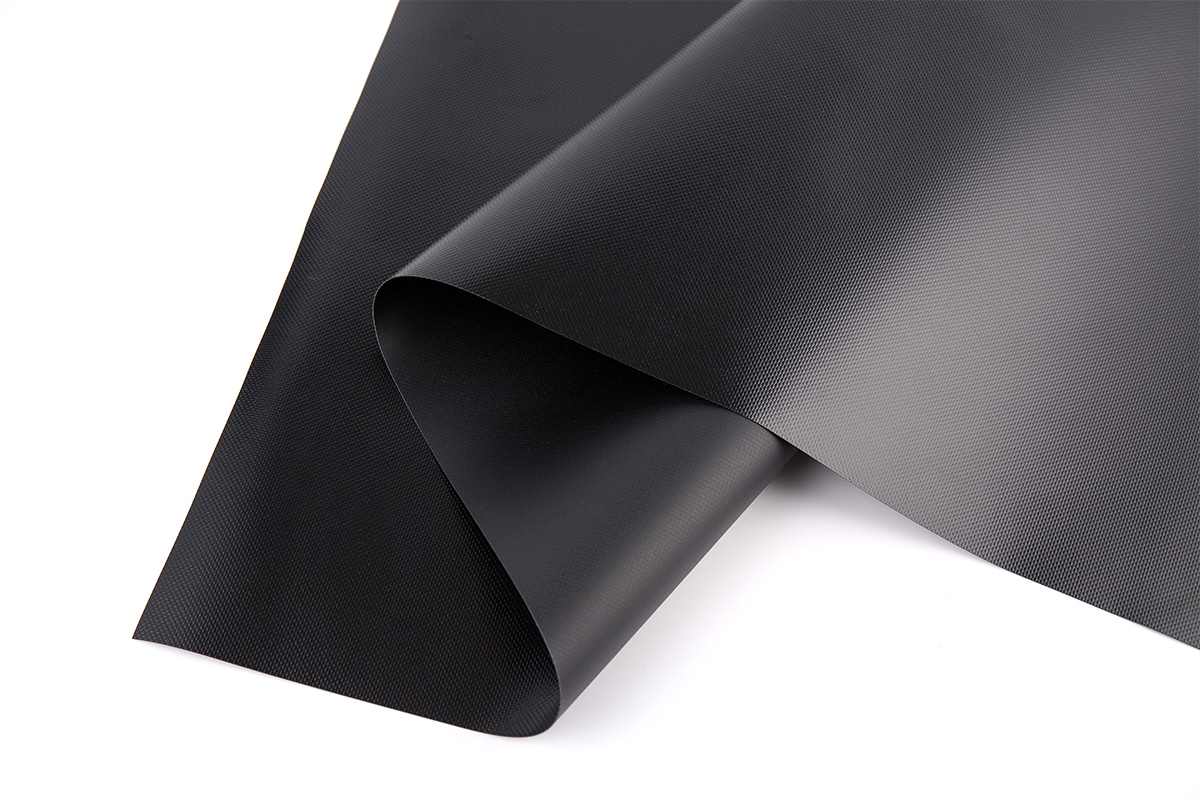

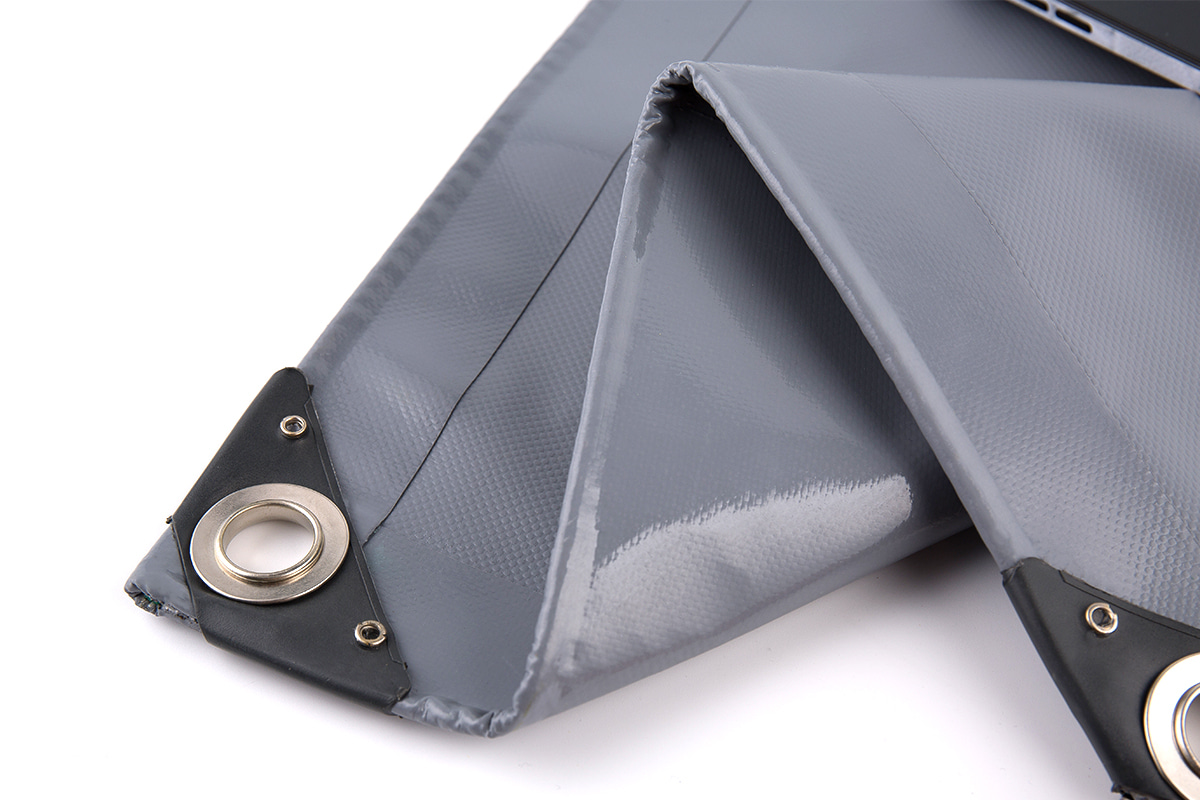

Apart from synthetic fibers, some car seat belt webbing manufacturers incorporate specialized coatings and finishes to enhance the webbing’s performance. For example, coatings can improve resistance to UV radiation, moisture, and chemicals, which helps prolong the lifespan of the seat belt webbing. These coatings also contribute to maintaining the webbing’s smooth texture, ensuring user comfort during regular use.

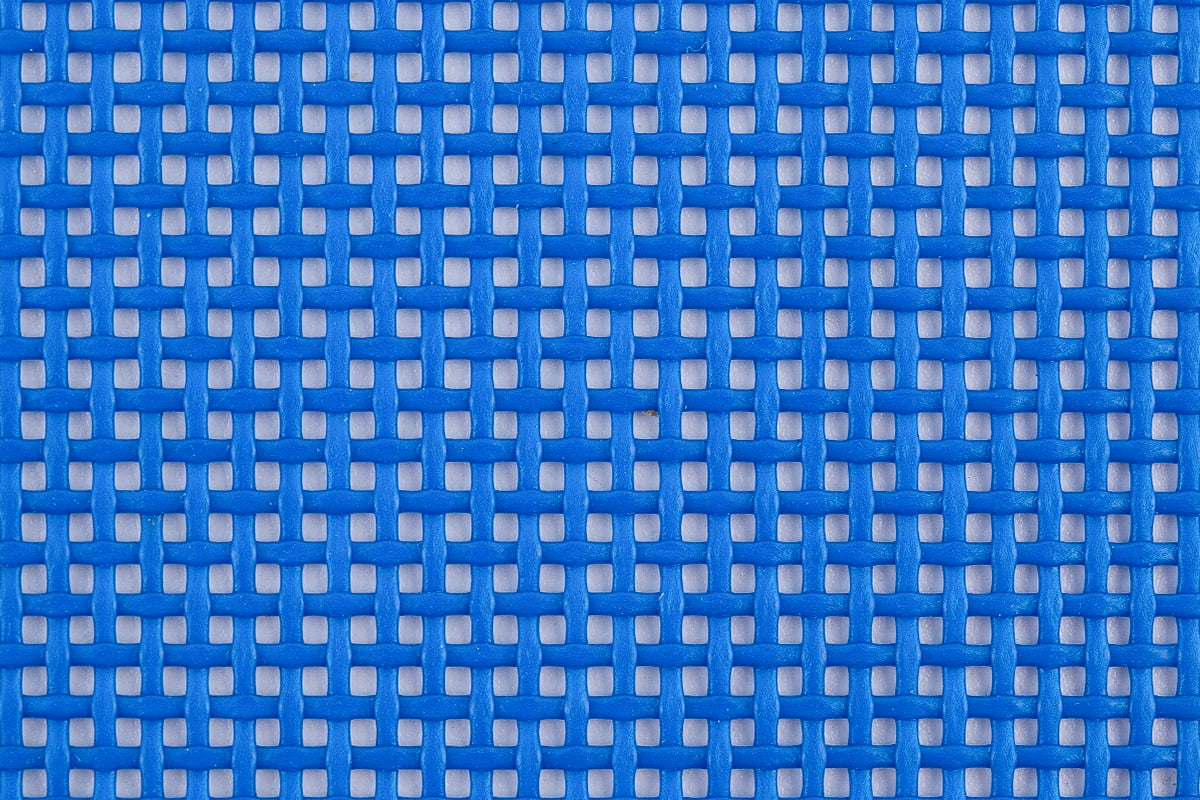

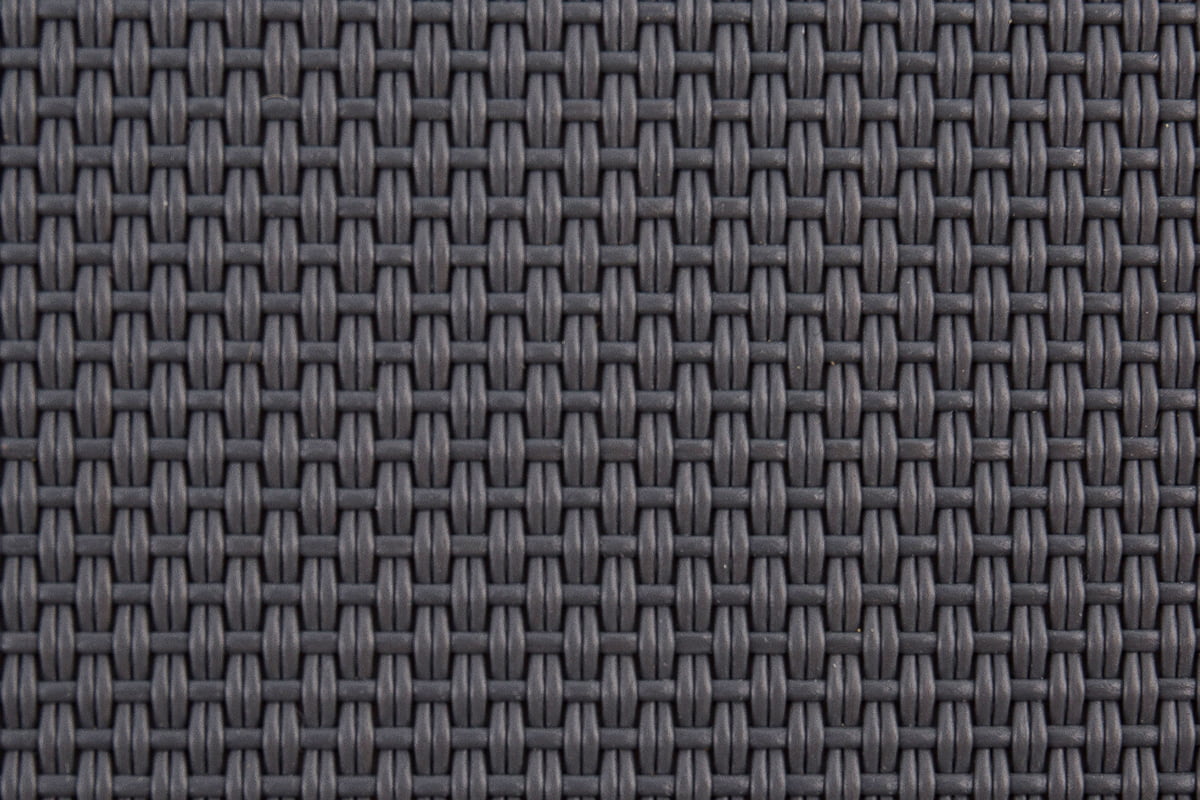

The weaving technique also plays a significant role in the final quality of car seat belt webbing. Manufacturers carefully design the weave pattern to optimize strength and flexibility. A tight weave can increase the webbing’s tensile strength, while specific patterns can enhance its ability to stretch and absorb energy during an impact.

Safety standards set by regulatory bodies guide car seat belt webbing manufacturers in selecting materials. These standards ensure that webbing performs reliably under different conditions, including mechanical stress. Manufacturers often test their webbing extensively to verify that the materials and construction meet or exceed these requirements.

The choice of materials by car seat belt webbing manufacturers directly affects the safety, durability, and comfort of the final product. Polyester and nylon are commonly used fibers, each offering unique advantages. Coatings and weaving techniques further enhance the webbing’s properties, ensuring that it can perform effectively in real-world conditions. By carefully selecting and combining these materials, car seat belt webbing manufacturers create products that contribute to vehicle safety and passenger protection.

en

en Español

Español