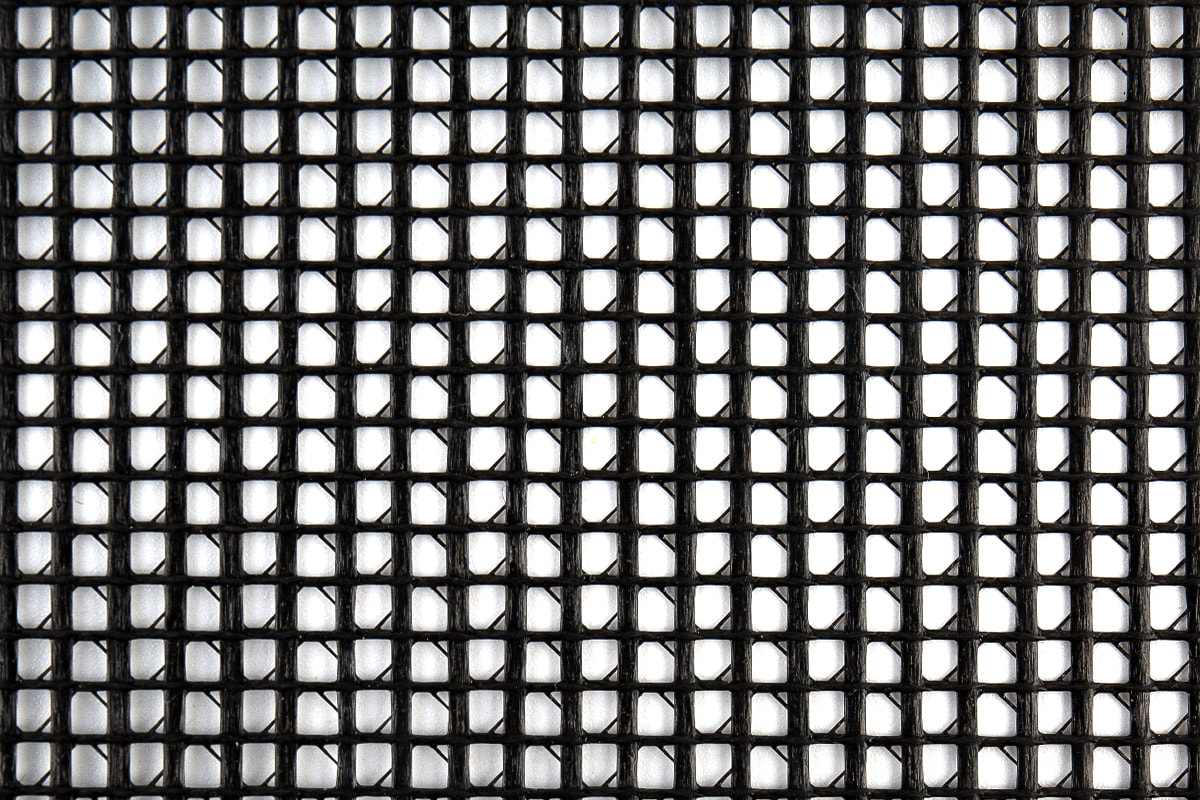

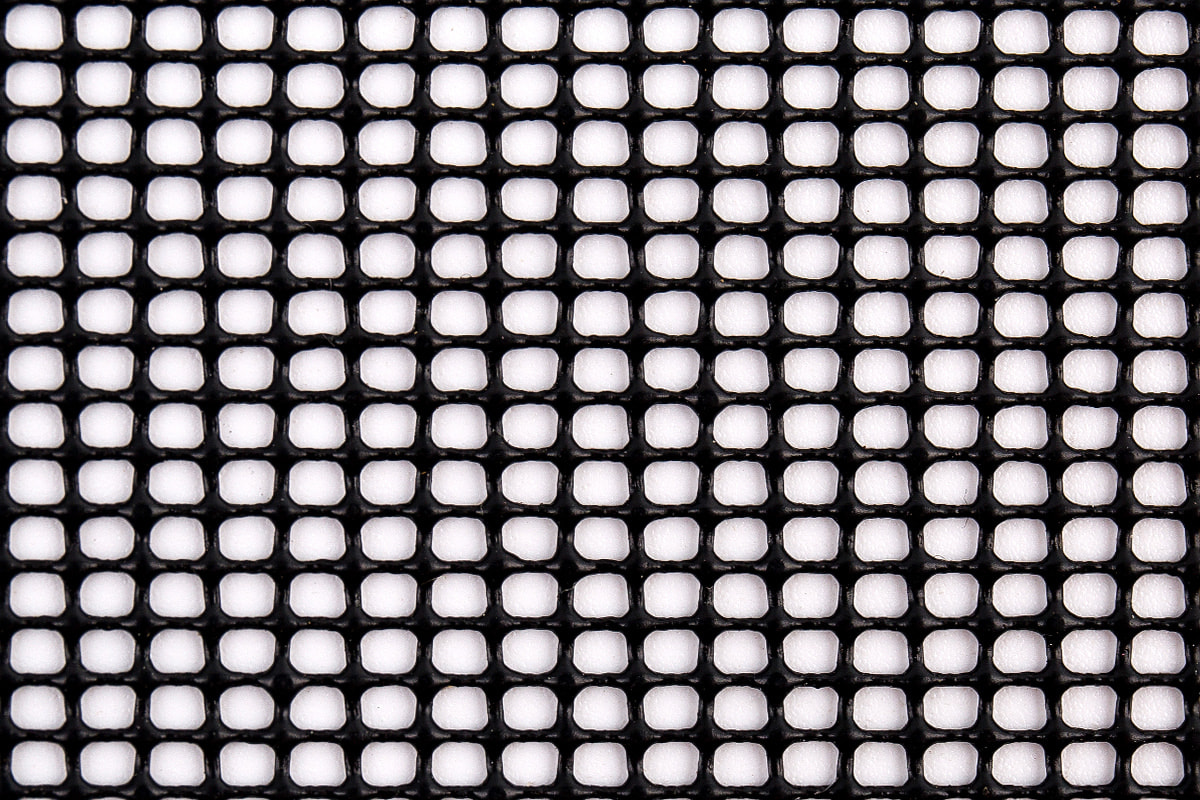

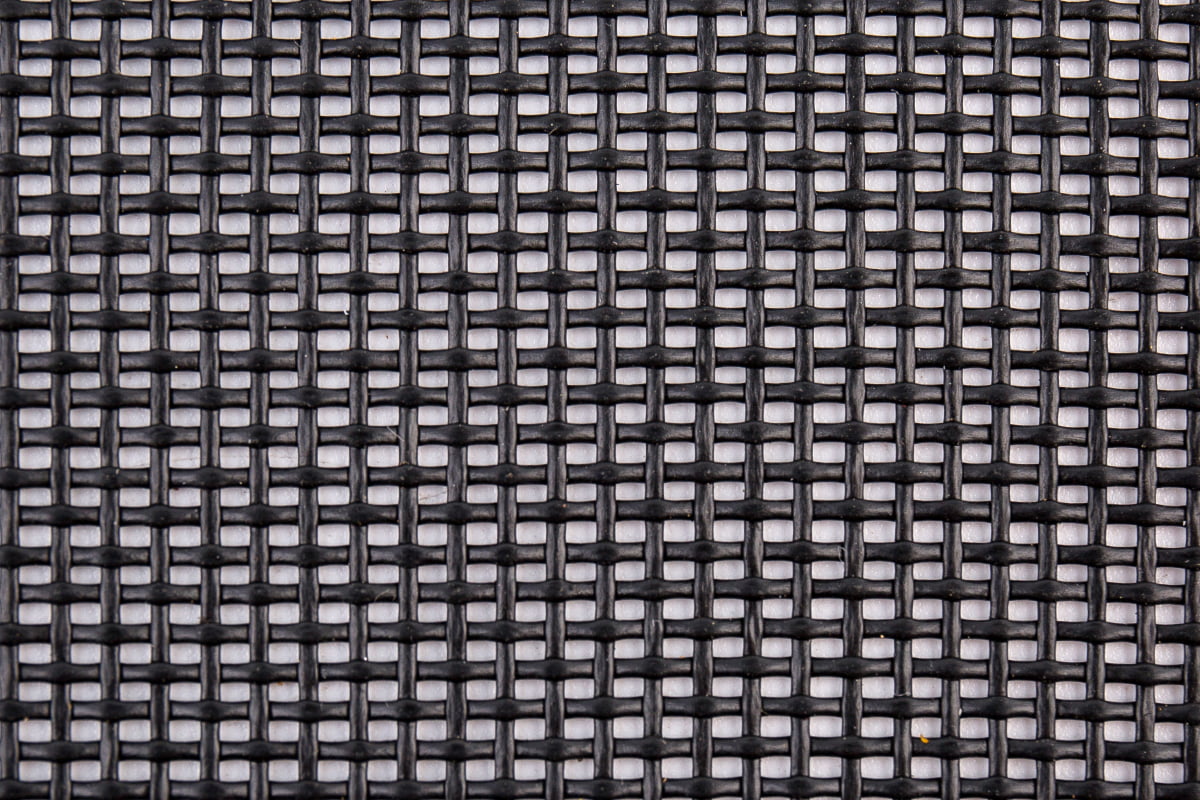

PVC coated polyester yarn is a versatile material widely used in various industries, including textiles, upholstery, industrial fabrics, and outdoor applications. Its unique combination of strength, flexibility, and resistance to environmental factors makes it a popular choice. However, selecting the right grade of PVC coated polyester yarn is essential to ensure the material meets the specific requirements of your project.

One of the key considerations when choosing PVC coated polyester yarn is the intended use of the final product. Different applications demand different properties from the yarn. For instance, outdoor products like awnings, tents, or tarpaulins require yarn with enhanced UV resistance and weatherproof capabilities. In contrast, upholstery or decorative fabrics may prioritize softness and colorfastness.

The grade of PVC coated polyester yarn is largely determined by the quality of the polyester base yarn and the thickness and composition of the PVC coating. Higher-grade yarns typically use polyester fibers with greater tensile strength and uniformity, which translates to better durability and performance. The PVC coating quality also plays a significant role in the yarn's resistance to abrasion, chemicals, and UV exposure.

Another important factor is the denier or thickness of the yarn. Denier affects the strength and texture of the coated yarn. For projects that require high tensile strength, such as industrial fabrics or heavy-duty covers, a thicker yarn with a heavier PVC coating may be more suitable. On the other hand, applications like fashion accessories or lightweight bags might benefit from finer yarns that allow more flexibility and a smoother finish.

Color and finish options are also relevant when selecting the right grade of PVC coated polyester yarn. Depending on the project, you may want yarn that holds vibrant colors without fading or discoloration over time. Some grades offer special coatings that enhance color retention and add resistance to dirt and stains. These features can extend the lifespan and maintain the appearance of the final product, especially in outdoor or high-traffic environments.

The method of manufacturing and quality control standards of the PVC coated polyester yarn supplier should not be overlooked. Consistency in yarn quality is crucial for reliable production outcomes. Suppliers who follow strict manufacturing protocols ensure that the yarn meets specific performance criteria such as tensile strength, elongation, and coating adhesion. Requesting samples and testing them under your project's expected conditions can provide insights into how the yarn will behave in real use.

Environmental considerations are increasingly important when selecting materials. Some grades of PVC coated polyester yarn use eco-friendlier PVC compounds or incorporate recycled polyester fibers. If sustainability is a priority for your project, inquire about the environmental certifications or practices of the yarn manufacturer. These aspects may influence your choice without compromising the material's functionality.

Cost is naturally a factor to weigh, but it should be balanced against the grade and performance needs. While higher-grade yarns might have a higher initial cost, they often provide better durability and reduce the need for repairs or replacements. Conversely, for projects with shorter lifespans or lower stress demands, mid-range or entry-level grades can offer a cost-effective solution.

In addition to technical specifications, communication with the PVC coated polyester yarn supplier can help tailor the material to your project. Some manufacturers provide custom coating thicknesses, colors, or fiber blends to better suit unique applications. Collaborating early with suppliers helps avoid mismatches between material properties and project demands.

Choosing the right grade of PVC coated polyester yarn involves evaluating the end use, required durability, tensile strength, color and finish, environmental impact, and cost. Understanding how these factors interact will guide you to a suitable yarn that supports the success of your project.

By focusing on quality, functionality, and specific project needs, you can select PVC coated polyester yarn that delivers reliable performance and satisfaction over time. This thoughtful approach ensures that the material you choose aligns well with your product's goals and usage environment.

en

en Español

Español