The quality of custom heavy duty mesh tarps largely depends on the manufacturing process used by suppliers and factories. This process influences the durability, strength, and overall performance of the tarps in various applications, from construction sites to agricultural uses. Understanding how the manufacturing steps impact the final product can help buyers make informed decisions when selecting custom heavy duty mesh tarps for their needs.

The important factors in the manufacturing process is the selection of raw materials. Custom heavy duty mesh tarps typically use high-density polyethylene (HDPE) or similar strong synthetic fibers as the base material. The quality and grade of these fibers determine the tarp’s resistance to tearing, UV exposure, and weather elements. Manufacturers who carefully source and test their raw materials provide a more reliable product that performs well in demanding environments.

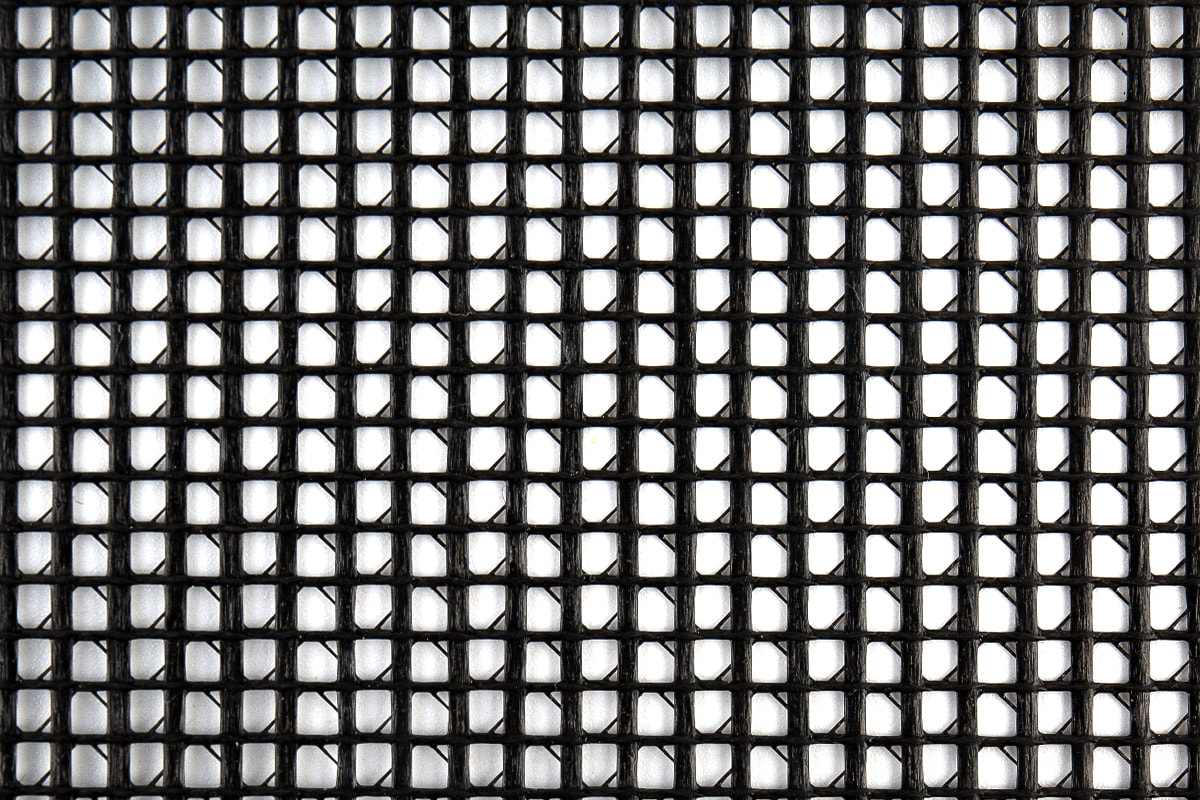

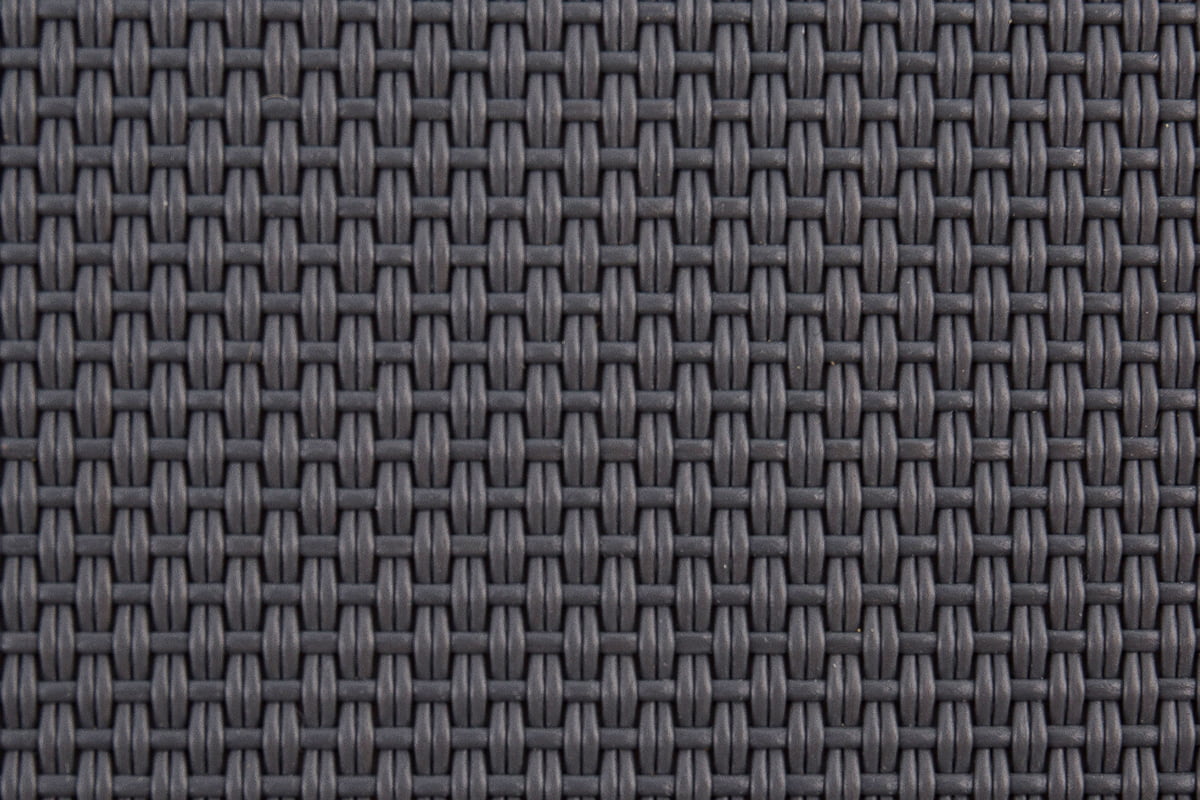

The weaving technique employed during production also plays a significant role in the quality of custom heavy duty mesh tarps. A tight and uniform weave ensures that the mesh fabric maintains its strength while allowing airflow and water drainage. This balance is essential because it reduces wind resistance and prevents water accumulation, which could otherwise damage the tarp or the covered items. Manufacturers with advanced weaving technology can create tarps with consistent mesh sizes and fewer weak points, resulting in better durability.

Another critical step in the manufacturing process is the coating or treatment applied to the mesh fabric. Many custom heavy duty mesh tarps undergo UV stabilization treatments to prevent damage from prolonged sun exposure. This treatment extends the life of the tarp by reducing fading, brittleness, and degradation. Additionally, coatings that improve water resistance and mildew prevention enhance the tarp’s suitability for outdoor use. The application of these treatments requires precision to ensure even coverage and long-lasting protection.

The fabrication stage, which includes cutting, hemming, and reinforcing, also affects the overall quality. Edges of custom heavy duty mesh tarps are often folded and double-stitched to prevent fraying and improve strength. Reinforced corners with heavy-duty grommets allow for secure fastening and reduce the chance of tearing under tension. Manufacturers that pay attention to these details produce tarps that withstand heavy use and harsh conditions without failure.

Quality control throughout the manufacturing process cannot be overlooked. Reputable manufacturers implement rigorous inspections to identify defects such as uneven weaving, weak seams, or poorly applied coatings. These checks ensure that each custom heavy duty mesh tarp meets required specifications before it reaches customers. Without strict quality control, tarps may fail prematurely, causing costly replacements and safety risks.

Customization options provided by manufacturers further influence quality. Being able to tailor mesh size, tarp dimensions, color, and reinforcement features allows users to obtain products designed specifically for their applications. Custom heavy duty mesh tarps made to fit exact requirements reduce waste and improve functionality, demonstrating how manufacturing flexibility contributes to product value.

The manufacturing process impacts the quality of custom heavy duty mesh tarps through raw material selection, weaving technique, coating application, fabrication details, and quality control measures. Each stage contributes to the tarp’s durability, strength, and suitability for various environments. When sourcing custom heavy duty mesh tarps, understanding these factors helps ensure that buyers receive reliable products that perform as expected in demanding situations.

en

en Español

Español