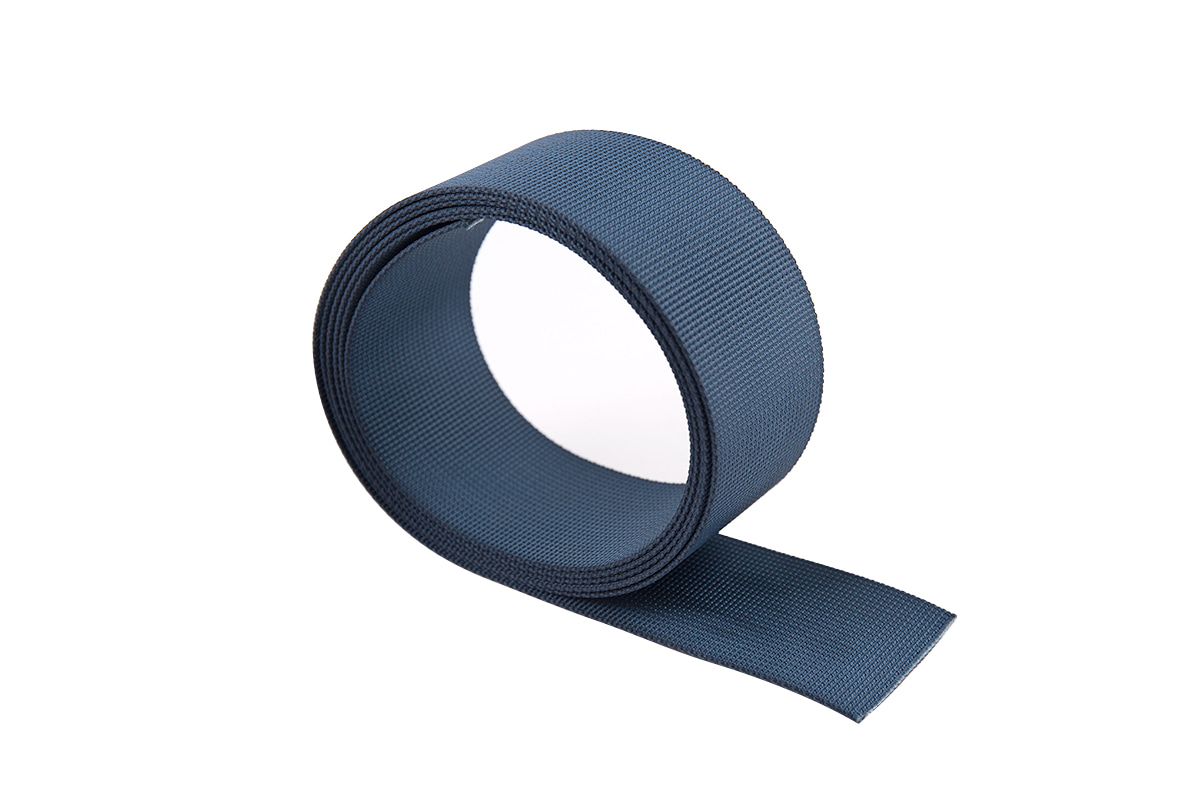

Car seat belts are critical for passenger safety, and one of the key components in their effectiveness is the seat belt webbing. The webbing, typically made from polyester or nylon, must be strong enough to withstand high forces in the event of a collision. Manufacturers put car seat belt webbing through rigorous testing to ensure it meets safety standards.

1. Tensile Strength Testing

One of the primary ways manufacturers test the strength of car seat belt webbing is through tensile strength testing. This test measures the amount of force that the webbing can withstand before it breaks or deforms. During the test, a sample of the seat belt webbing is pulled at a constant rate until it fails. The force required to break the webbing is recorded, providing data on the material's strength.

Tensile strength testing is essential because car seat belts need to withstand significant forces during an accident. The webbing must not snap under pressure, ensuring that it can restrain the occupant effectively during a collision.

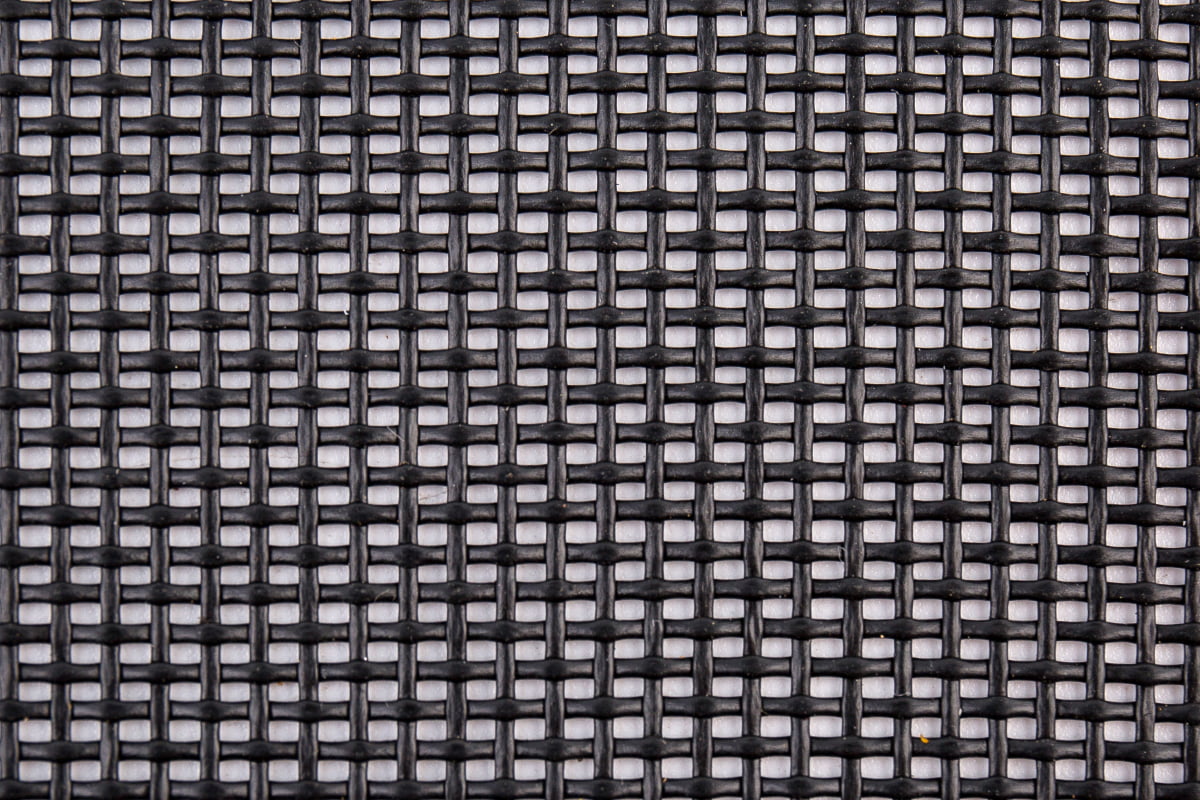

2. Abrasion Resistance Testing

Car seat belts are designed for daily use, and the webbing must be durable enough to withstand wear and tear over time. Manufacturers test the abrasion resistance of car seat belt webbing by subjecting it to frictional forces. In this test, the webbing is rubbed against a rough surface for a set number of cycles to simulate the wear it would experience over years of use.

The goal of abrasion resistance testing is to ensure that the seat belt webbing maintains its integrity and strength, even after extended exposure to friction, dirt, and environmental factors. This ensures that the webbing will continue to perform as expected throughout its lifespan.

3. Elongation and Stretch Testing

Another important test for car seat belt webbing is elongation and stretch testing. During this test, manufacturers apply a force to the webbing and measure how much it stretches before it reaches its breaking point. This test simulates the forces exerted on the webbing during a crash and helps to evaluate how much the webbing can stretch without losing its effectiveness in restraining the occupant.

Seat belt webbing must have some degree of stretch to absorb impact energy, but it should not stretch excessively, as this could compromise its ability to hold the passenger in place during an accident. The results of this test help manufacturers ensure the webbing has the right balance of flexibility and strength.

4. UV Resistance Testing

Car seat belts are exposed to sunlight, which can cause materials to degrade over time. Manufacturers test the UV resistance of car seat belt webbing by exposing samples to simulated sunlight for extended periods. This test evaluates how well the webbing resists UV damage, which can weaken the material and reduce its strength.

Webbing that is resistant to UV degradation will last longer and maintain its strength, ensuring that the seat belt remains effective throughout the vehicle's lifespan.

5. Certification Standards and Compliance

Manufacturers also ensure that their car seat belt webbing meets international safety standards, such as those set by the Federal Motor Vehicle Safety Standards (FMVSS) in the United States or the European Union's ECE regulations. These standards define the strength requirements for car seat belt webbing, and manufacturers must conduct a series of tests to verify compliance.

The strength of car seat belt webbing is critical for passenger safety, and manufacturers subject the material to various rigorous tests to ensure its durability and reliability. From tensile strength and abrasion resistance to UV testing, these evaluations help ensure that the seat belt webbing will perform effectively in real-world conditions. By meeting these standards, manufacturers provide consumers with a product that offers both safety and longevity.

en

en Español

Español