Sunscreen mesh fabric is a key material used in outdoor products like shade sails, canopies, and protective clothing. Its ability to block harmful UV rays while still allowing airflow makes it ideal for creating sun protection solutions. However, ensuring that this fabric performs as intended requires careful design, testing, and manufacturing processes. But how exactly do manufacturers ensure the effectiveness of sunscreen mesh fabric?

Material Selection and UV Protection

The foundation of any effective sunscreen mesh fabric begins with the choice of materials. High-quality synthetic fibers, such as polyester or nylon, are often chosen for their ability to withstand the elements. These fibers are naturally resistant to UV radiation, but the fabric’s overall UV blocking capabilities depend on the weaving technique and the incorporation of special UV-blocking additives. Manufacturers may treat the yarn with a UV stabilizer during production, which helps enhance the fabric's ability to block sunlight without compromising its flexibility and strength.

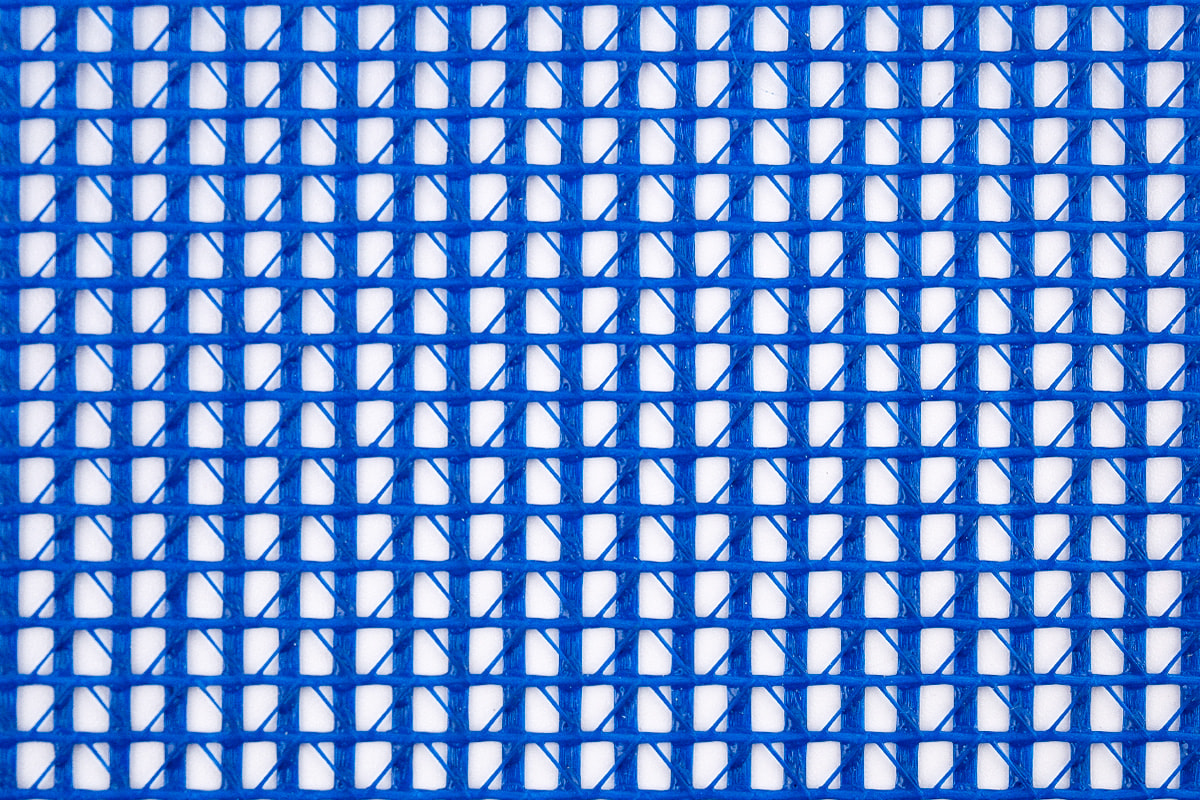

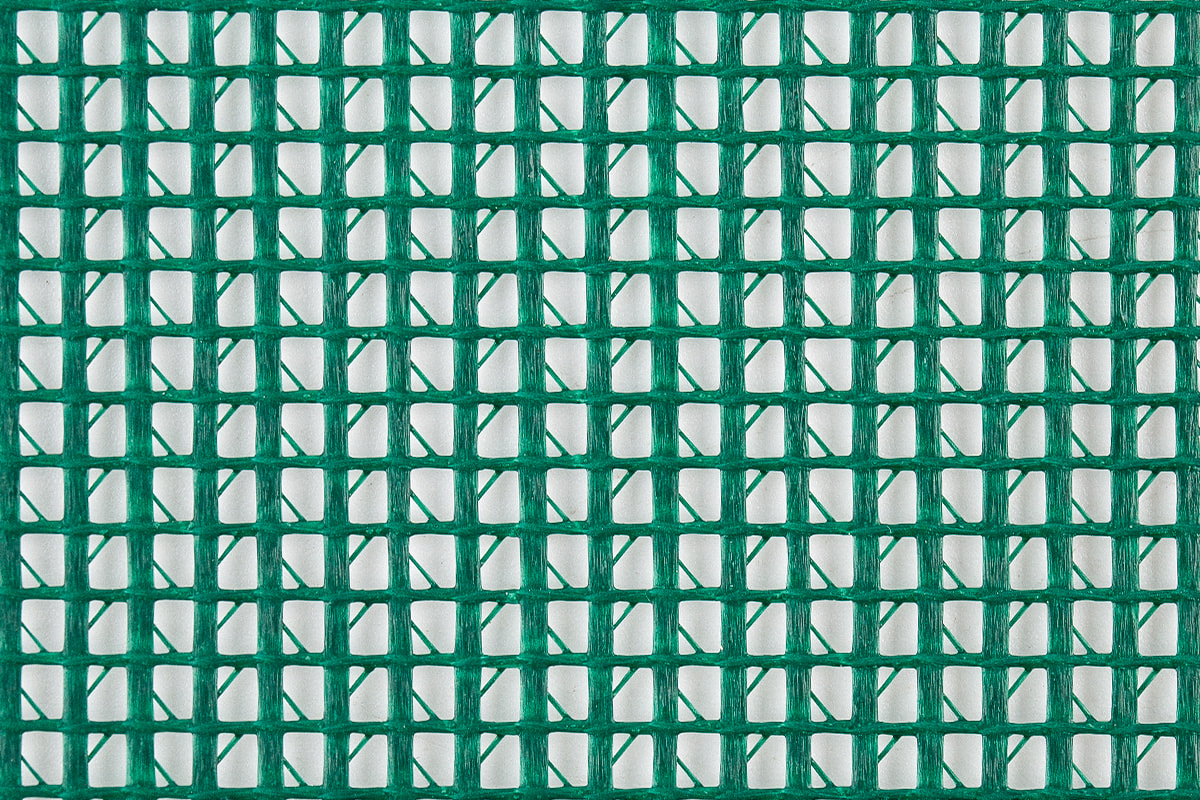

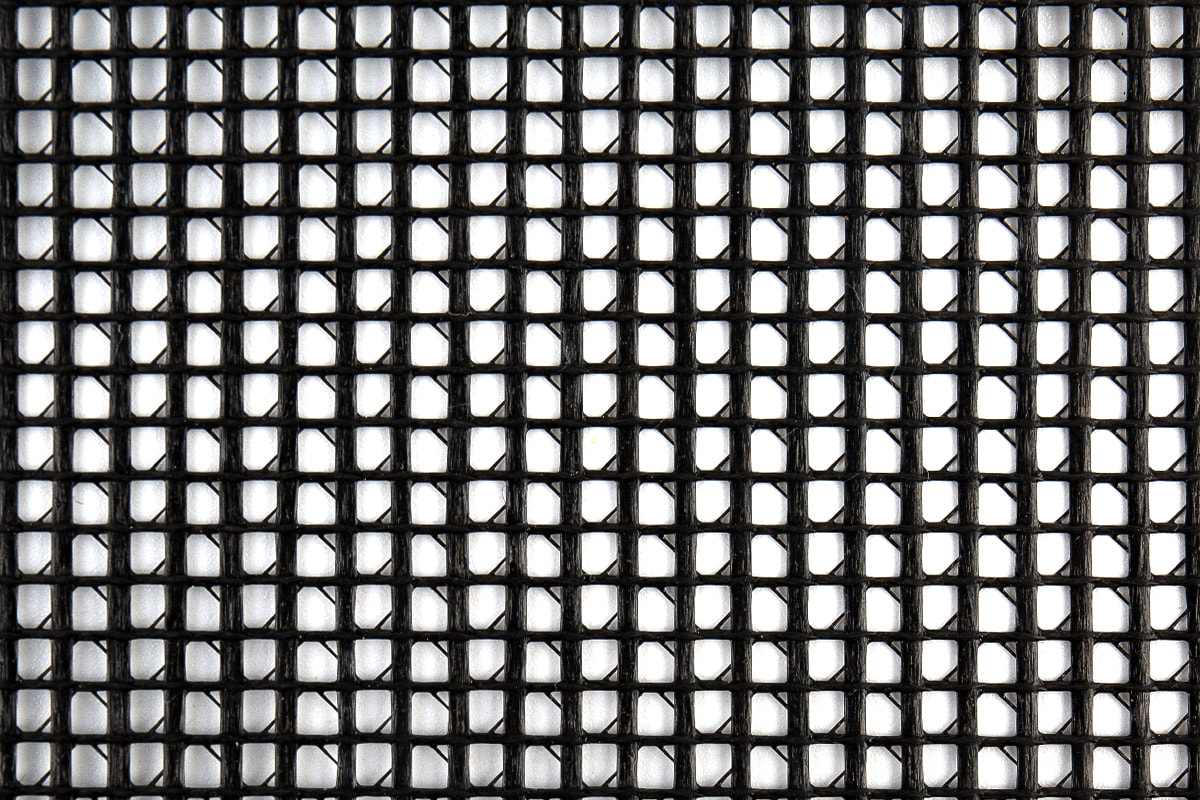

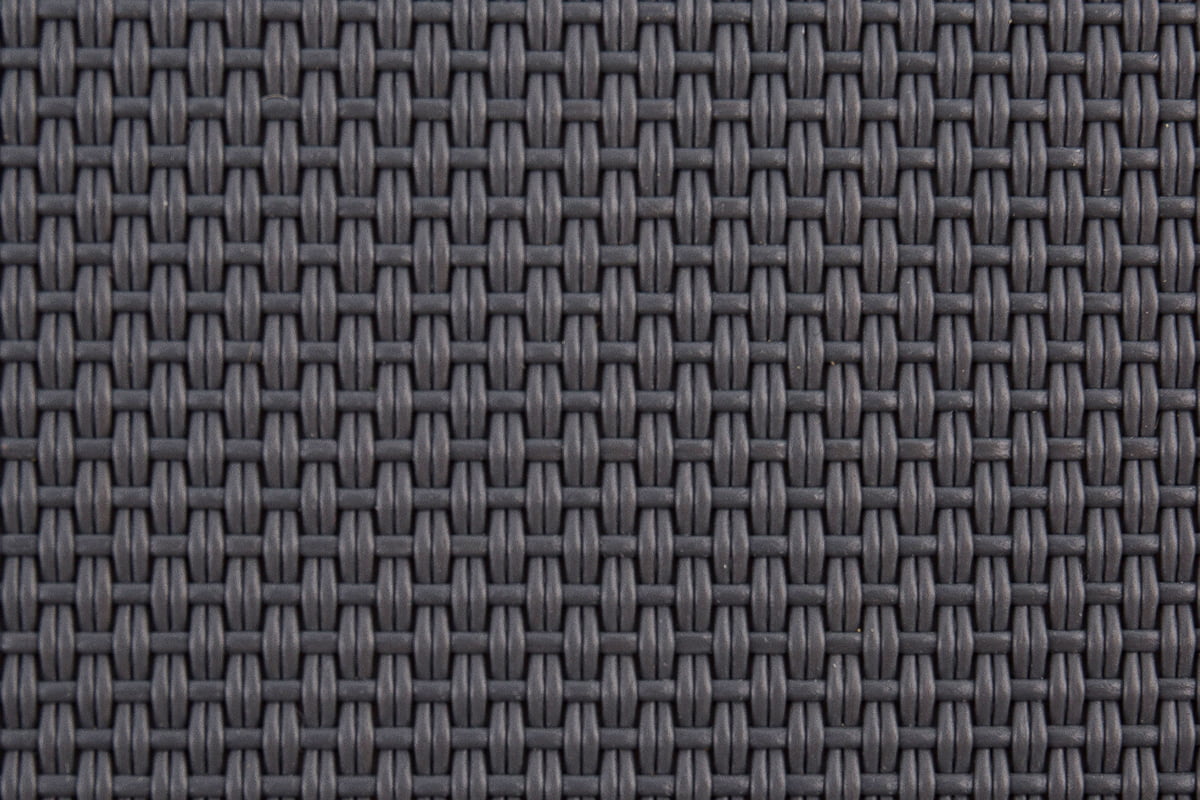

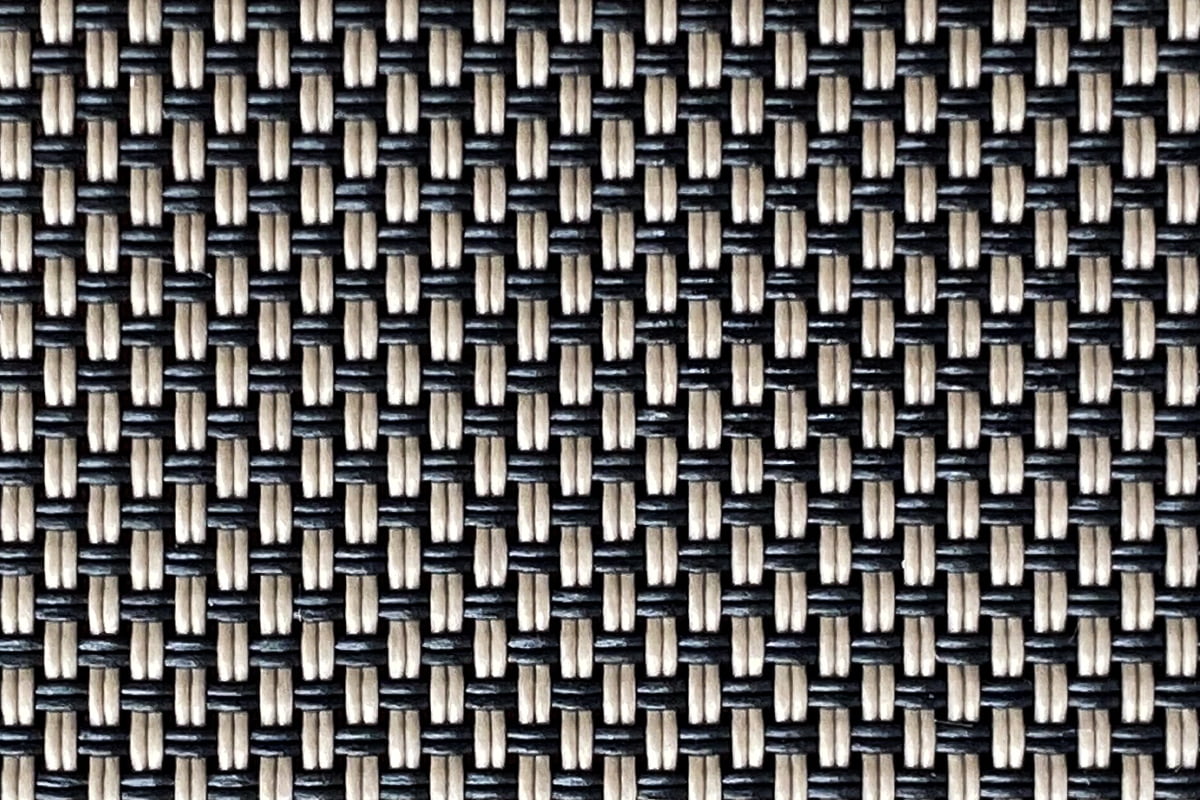

Weaving and Construction Techniques

The way the fabric is woven also plays a significant role in its UV protection. Sunscreen mesh fabric often features a specific weave pattern that ensures a balance between strength and UV shielding. A tightly woven pattern can increase the UV block, while a looser weave allows more light to penetrate. The design of the weave also contributes to the fabric’s durability and resistance to wear. Manufacturers often use advanced weaving techniques that enhance the fabric’s ability to resist fading, degradation, or stretching over time.

Testing for UV Protection

Once sunscreen mesh fabric is produced, manufacturers subject it to rigorous testing to ensure it meets specific UV protection standards. The UV protection factor (UPF) rating is a key indicator of how well a fabric blocks harmful UV rays. UPF is measured based on how much UV radiation can pass through the fabric. A higher UPF rating indicates better protection.

Manufacturers typically perform lab tests that simulate real-world exposure to UV rays. These tests measure how much UV radiation the fabric allows to pass through after hours of exposure to intense sunlight. Based on the results, the fabric is assigned a UPF rating. Sunscreen mesh fabric typically ranges from a UPF of 30 to 50+, which ensures that only a small fraction of harmful UV rays can penetrate the material.

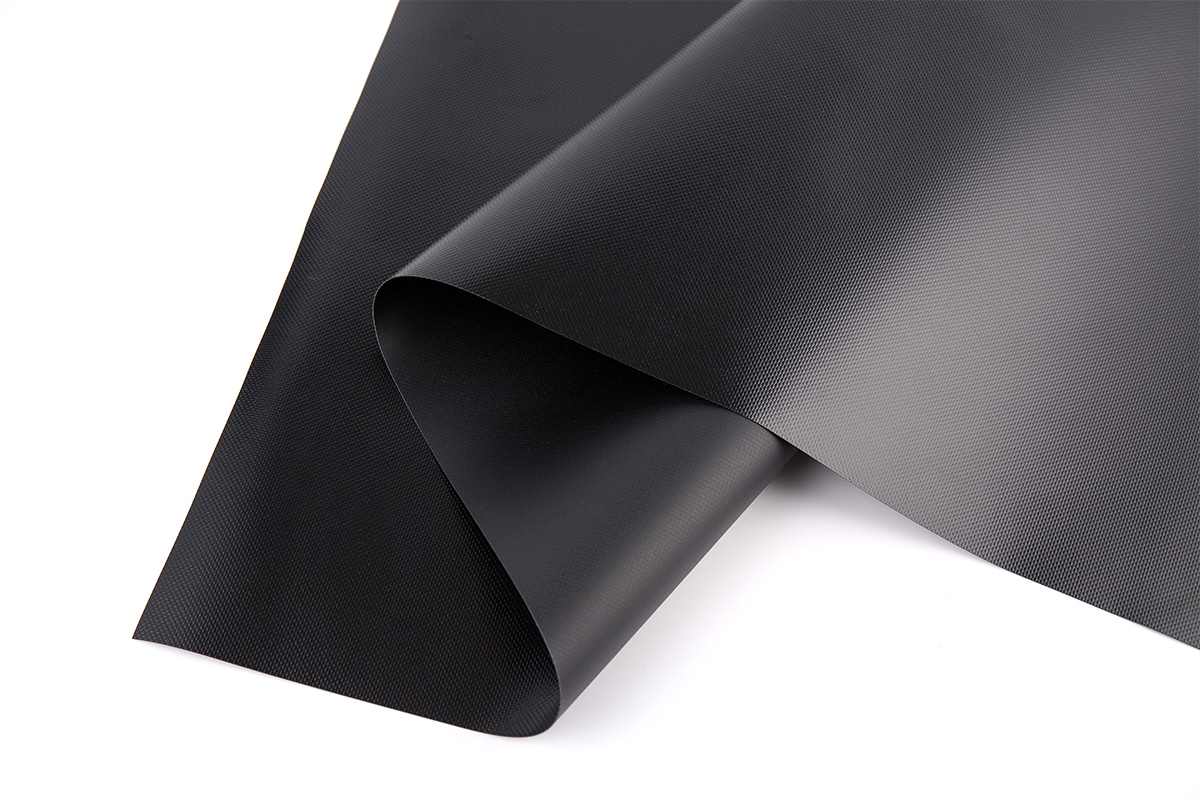

Durability and Longevity

To ensure that sunscreen mesh fabric maintains its effectiveness over time, manufacturers focus on creating a durable product. Sun exposure, wind, and rain can degrade the fabric, causing it to lose its protective capabilities. Therefore, durability is a critical factor in its design.

Manufacturers often incorporate anti-fade treatments and water-resistant coatings into the fabric. These treatments help the sunscreen mesh fabric maintain its appearance and UV-blocking abilities even after long-term use in outdoor conditions. Additionally, the material is often tested for its resistance to fading, shrinkage, and abrasion, ensuring that it will continue to offer reliable protection year after year.

Manufacturers ensure the effectiveness of sunscreen mesh fabric through a combination of careful material selection, advanced weaving techniques, UV treatments, and rigorous testing. The result is a versatile fabric that provides reliable sun protection while maintaining comfort and durability. Whether used in outdoor gear or architectural applications, sunscreen mesh fabric continues to be a popular choice for those seeking effective UV protection for both personal and structural use.

en

en Español

Español