PVC coated polyester mesh fabric is widely used in industries such as construction, agriculture, transportation, and outdoor furniture due to its durability, flexibility, and resistance to environmental factors. The quality and performance of this fabric depend heavily on the coating techniques applied during production. Different methods of coating not only impact the physical properties of the material but also determine its suitability for various applications. Understanding how coating techniques affect this fabric helps manufacturers and users select the right type for their specific needs.

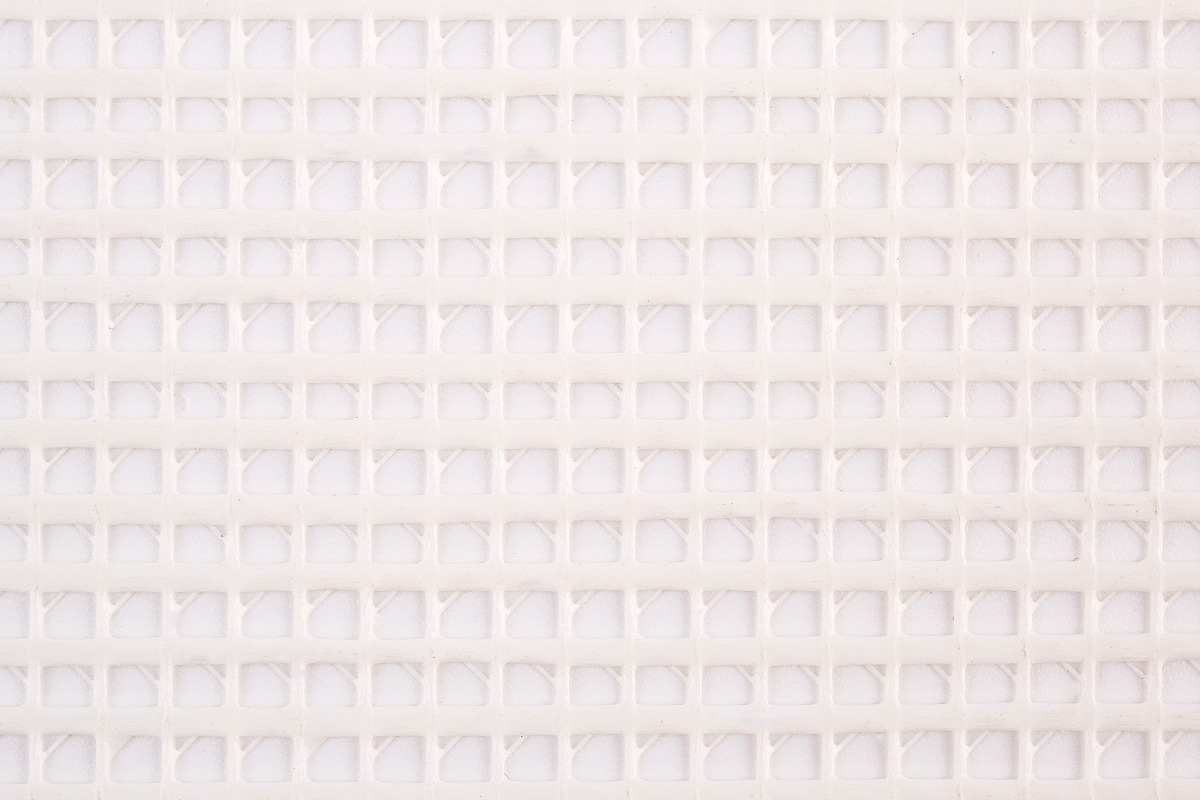

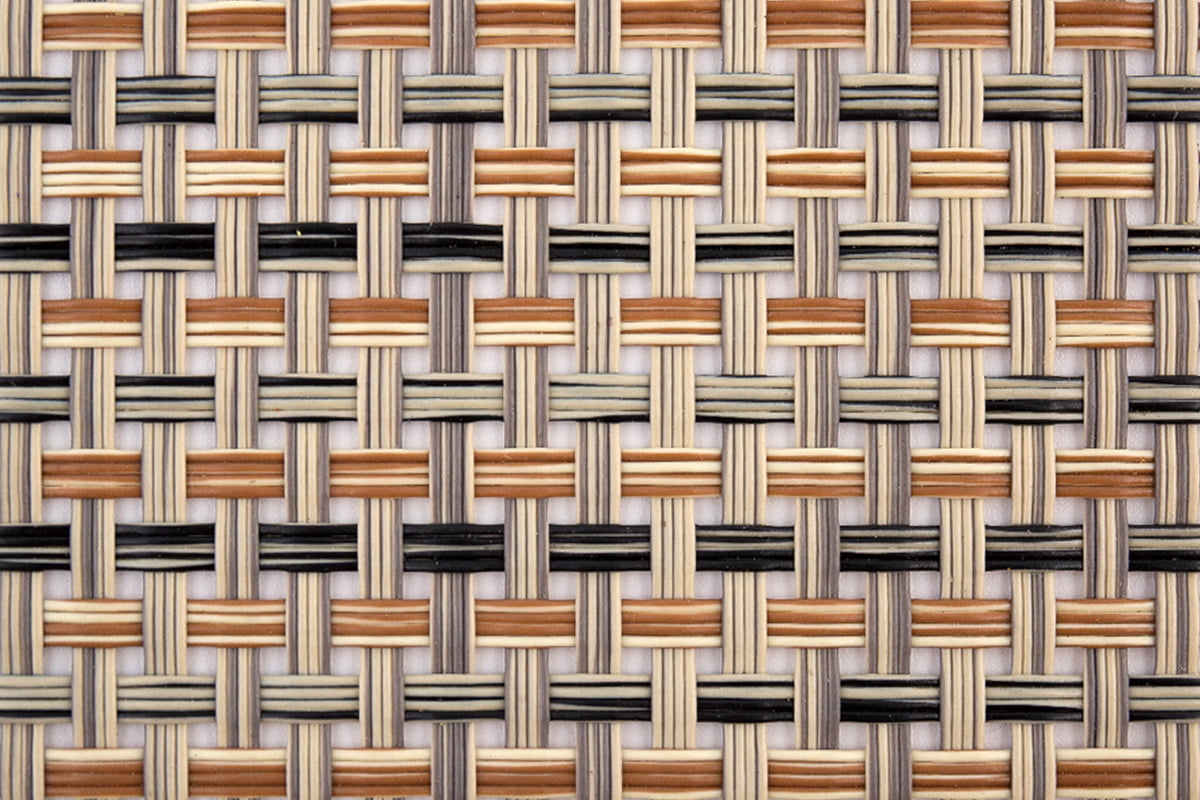

The foundation of PVC coated polyester mesh fabric is a woven polyester mesh. This base provides tensile strength, dimensional stability, and structural support. The PVC (polyvinyl chloride) coating is then applied to enhance properties such as water resistance, UV protection, flame retardancy, and ease of cleaning.

The way the PVC is applied—whether through knife coating, calendaring, or dip coating—has a direct effect on the final product's consistency, appearance, and performance. The uniformity, thickness, and adhesion of the coating all influence how well the fabric functions in different environments.

One common method used in manufacturing PVC coated polyester mesh fabric is knife coating. In this technique, the liquid PVC is spread evenly across the fabric using a blade. The gap between the knife and the fabric determines the coating thickness.

Knife coating offers good control over thickness and is ideal for applications where the fabric must maintain breathability while gaining weather resistance. However, achieving uniformity can be challenging if the fabric has any irregularities in the weave, which may result in slight variations in coating quality.

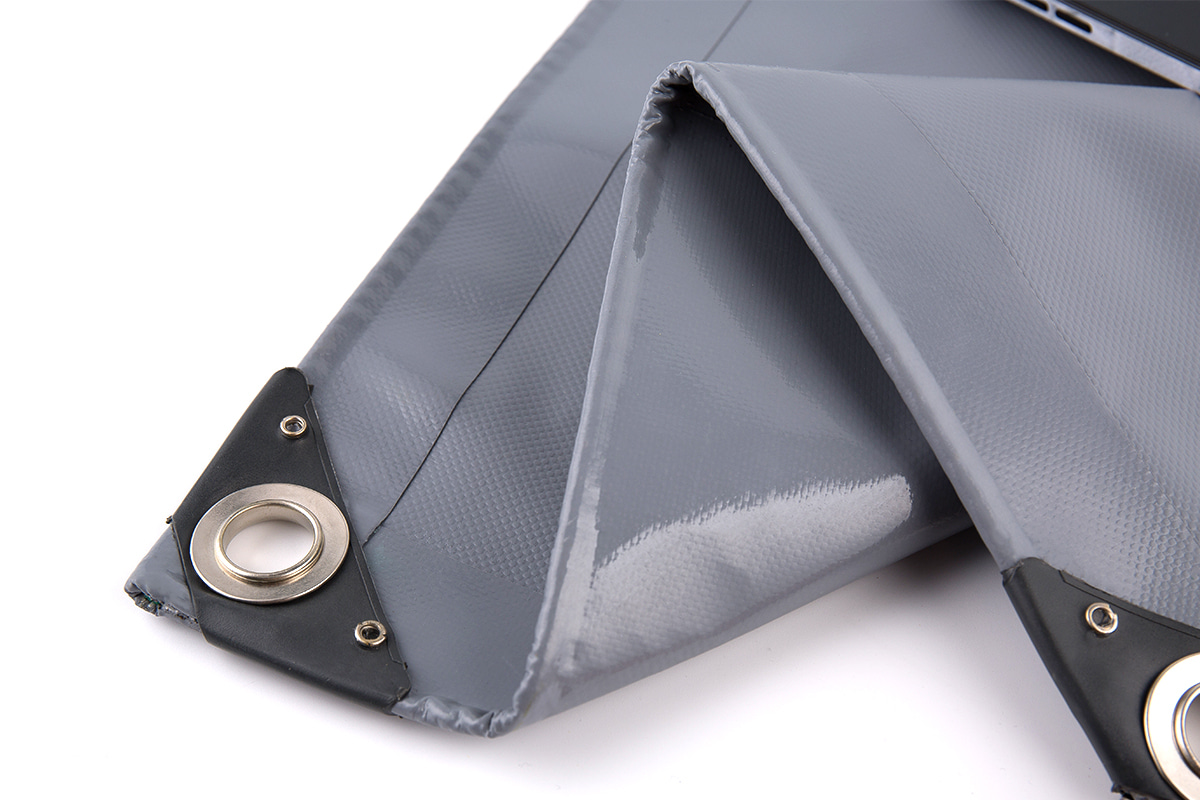

Calendaring involves passing the polyester mesh through heated rollers, which press and bond the PVC coating onto the surface. This method ensures a smooth, glossy finish and consistent thickness. PVC coated polyester mesh fabric produced through calendaring is often used in architectural applications, sunshades, or signage where appearance matters.

Calendaring can also improve bonding between layers, enhancing the durability and longevity of the fabric. However, this method may result in a stiffer texture, which might not be suitable for applications that require high flexibility.

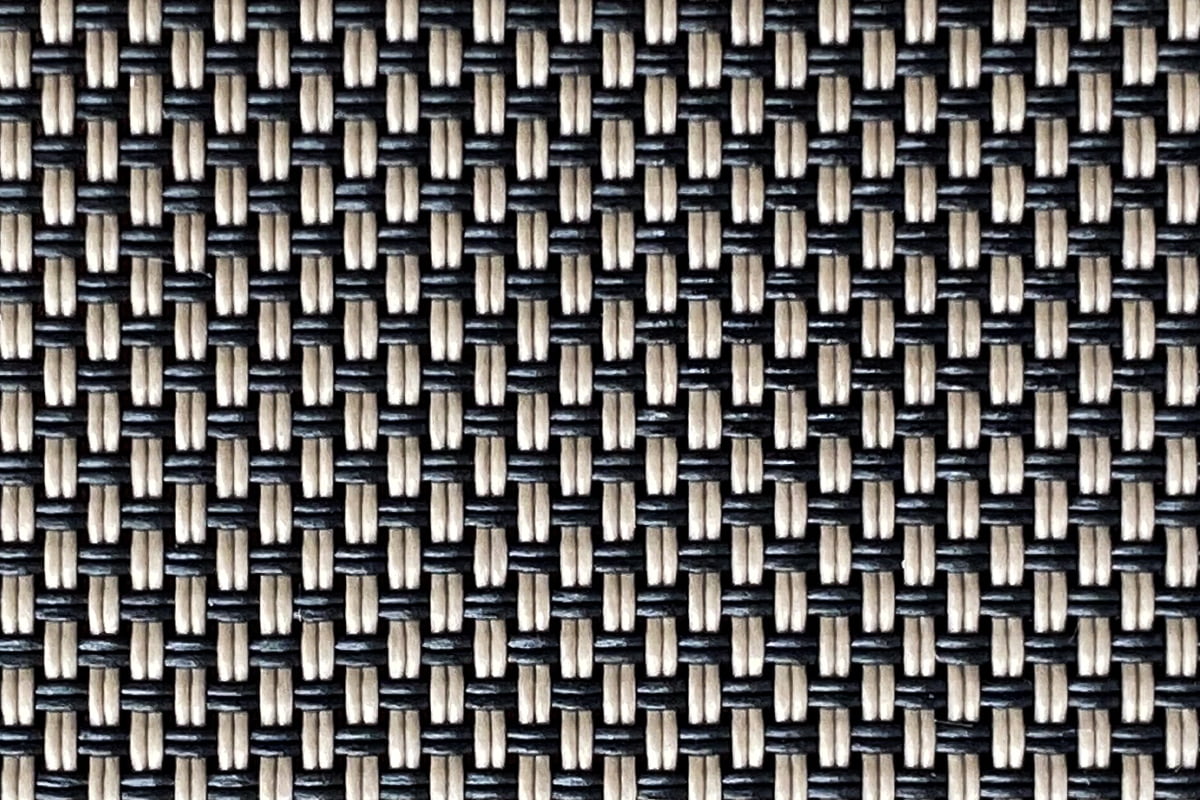

Dip coating, as the name suggests, involves immersing the polyester mesh into liquid PVC. This allows the coating to penetrate deeper into the fibers, providing thorough coverage and better encapsulation.

PVC coated polyester mesh fabric created through dip coating offers strong protection against moisture and chemical exposure. It is well-suited for uses in industrial or agricultural settings where the fabric is exposed to harsh environments.

Each coating method influences the quality of PVC coated polyester mesh fabric in different ways. Thinner coatings may offer better airflow and flexibility, while thicker coatings provide enhanced durability and resistance to abrasion or chemicals. The choice of technique depends largely on the intended application and the balance required between strength, breathability, and surface appearance.

The quality of the coating also depends on factors such as temperature control, curing time, and adhesion to the polyester base. Inconsistent processing can cause peeling, cracking, or early degradation under UV exposure.

The coating technique used in manufacturing PVC coated polyester mesh fabric plays a crucial role in determining its quality and suitability for specific applications. Whether through knife coating, calendaring, or dip coating, each method offers unique advantages and trade-offs. Selecting the right process ensures that the final fabric meets performance expectations and stands up to the conditions in which it will be used.

en

en Español

Español